____________________________________________________________________________________________________________

PFT G 5 c FU 230 4

Table of Contents 01.2005

____________________________________________________________________________________________________________

________________________________________________________________________________________

Knauf PFT GmbH & Co. KG Telephone 09323 / 31-760

PO Box 60 Telefax 09323 / 31-770

D-97343 Iphofen Internet www.pft.de

________________________________________________________________________________________

General information............................................................................................................................................1

PFT sales information.........................................................................................................................................3

Table of contents................................................................................................................................................4

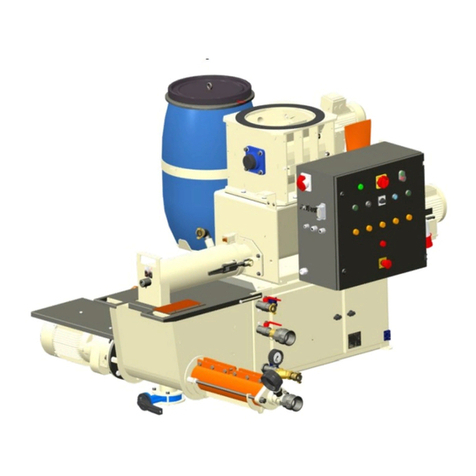

Overview.............................................................................................................................................................5

Water manifold ...................................................................................................................................................6

Air manifold.........................................................................................................................................................7

Description of functions ......................................................................................................................................9

Basic safety instructions .................................................................................................................................. 10

Setting values ...................................................................................................................................................12

Mortar pump .....................................................................................................................................................13

Initial Start.........................................................................................................................................................15

Mortar consistency / spraying guns and nozzles / interruption of work.............................................................19

Measures at the end of work and when cleaning .............................................................................................20

Check list..........................................................................................................................................................22

Clearing hose blocks ........................................................................................................................................24

Maintenance .....................................................................................................................................................25

Accessories ......................................................................................................................................................27

Circuit diagrams................................................................................................................................................28

Spare part lists..................................................................................................................................................30

Technical data ..................................................................................................................................................44