PFT G 5 SUPER Operating Manual Issued 11.2008

Knauf PFT GmbH & Co.KG

4

Contents

Dear PFT customer ....................................................................................................................... 3

Contents ........................................................................................................................................ 4

Applications: .................................................................................................................................. 6

Proper use of the machine ............................................................................................................ 6

Description of functions ................................................................................................................. 6

Dangers and warning symbols ...................................................................................................... 7

Basic safety instructions................................................................................................................ 8

Basic safety instructions................................................................................................................ 9

Signs ........................................................................................................................................... 11

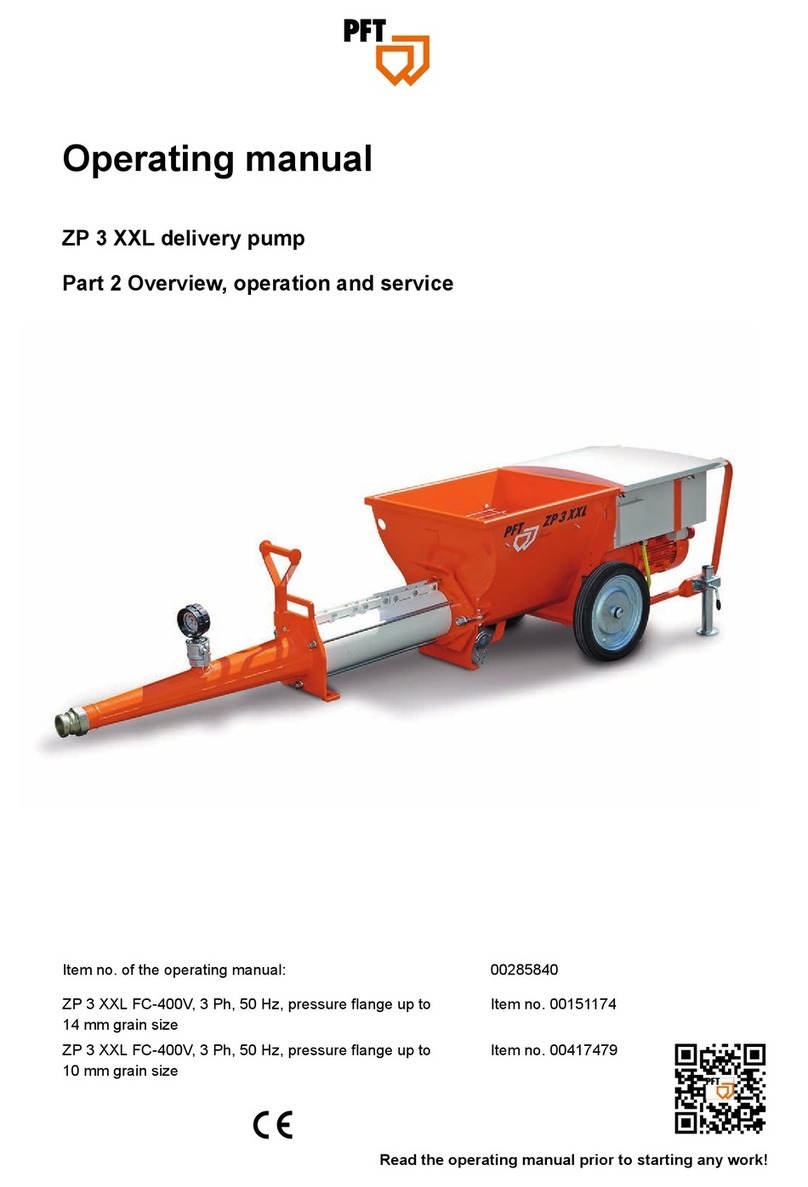

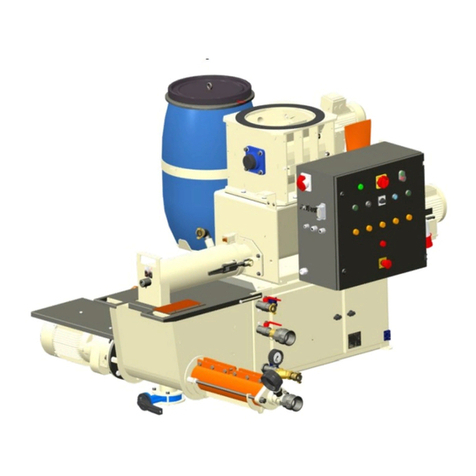

Overview of G 5 SUPER: ltem number 00 00 84 05 ................................................................... 13

Overview of CADDY G 5 SUPER: ltem number 00 00 82 15...................................................... 14

Overview of control box G 5 SUPER: ltem number 00 00 71 34................................................. 15

Overview of water / air manifold .................................................................................................. 16

Technical Specifications.............................................................................................................. 17

Caddy Icons ................................................................................................................................ 18

Settings ....................................................................................................................................... 19

Settings ....................................................................................................................................... 19

Mortar pressure ........................................................................................................................... 20

PFT pump components ............................................................................................................... 20

Checking the conveying pressure and back pressure................................................................. 21

Pump System adjustable............................................................................................................. 22

Start-up........................................................................................................................................ 23

Setting the water factor ............................................................................................................... 25

Procedures at the End of Work and Cleaning ............................................................................. 29

Getting Rid of Hose Blocks ......................................................................................................... 31

Measures for Power Failure and Water Supply Failure............................................................... 31

Measures for Water Supply Failure............................................................................................. 32

Measures for Suzero Temperatures............................................................................................ 32

Transport ..................................................................................................................................... 34

Maintenance................................................................................................................................ 34

Accessories ................................................................................................................................. 35

Fault – Cause – Remedy............................................................................................................. 36

Spare parts list for chassis G 5 SUPER: part no. 00008223....................................................... 38

Spare parts list geard motor / mixing tube................................................................................... 40

Spare parts list pump unit / mortar pressure gauge .................................................................... 42

Spare parts list chassis caddy, compressor K2N and manifold box............................................ 44

Spare parts list water manifold G 5 SUPER: part no. 00008260................................................. 46