Mixing pump RITMO XL 400V Overview – Operation

Table of Contents

2019-12-11

3

1

EC Declaration of Conformity..................... 5

2

General notes............................................... 6

2.1

Information about operating

instructions........................................... 6

2.2

Please retain the instructions for

later use............................................... 6

2.3

Division................................................ 6

3

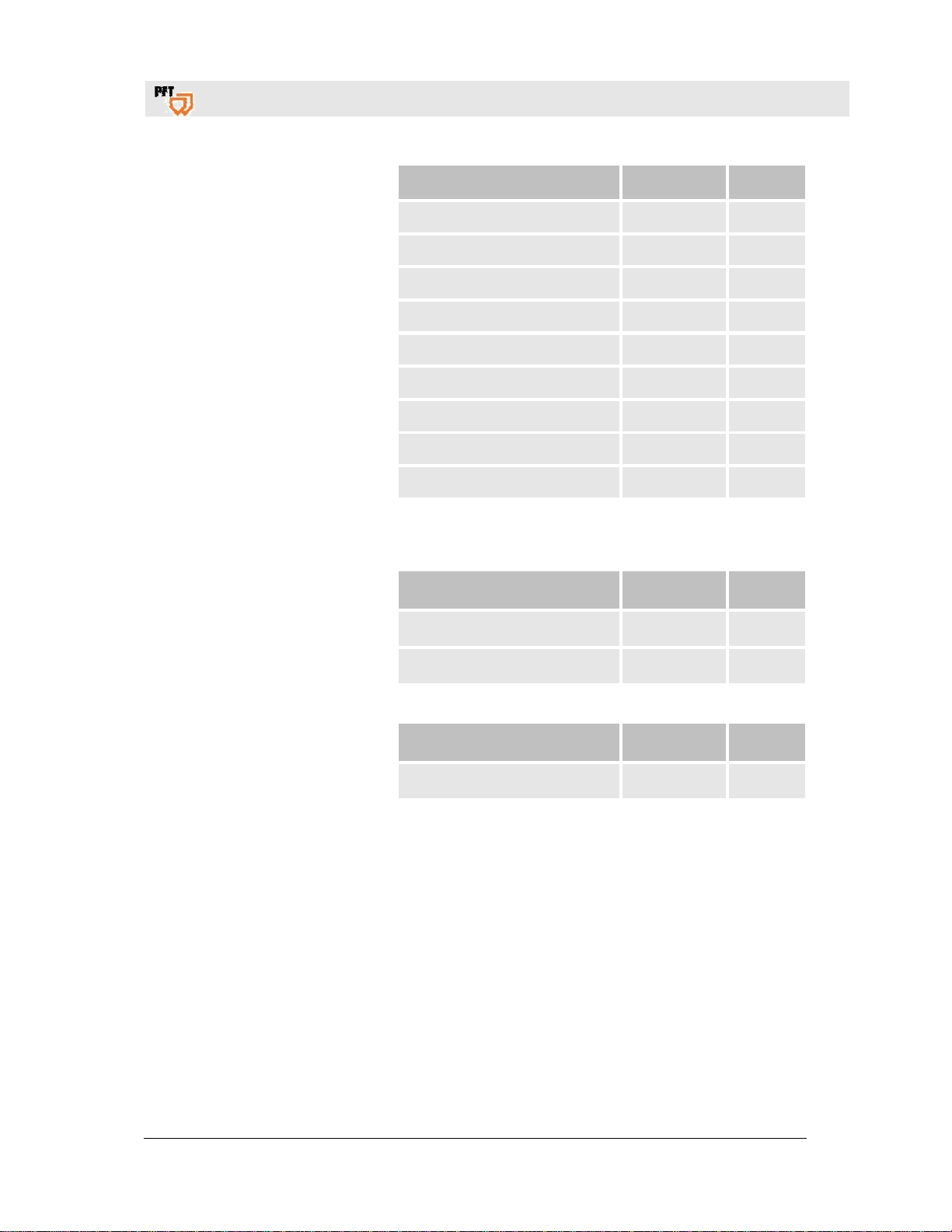

Spare part lists............................................. 7

3.2

Technical data ..................................... 8

3.3

General data........................................ 8

3.4

Connection values............................... 8

3.5

Operating conditions............................ 9

3.6

Performance values........................... 10

3.7

Noise level......................................... 10

3.8

Vibrations........................................... 10

3.9

Dimension sheet................................ 11

3.10

Type plate.......................................... 11

3.11

Quality control sticker........................ 11

4

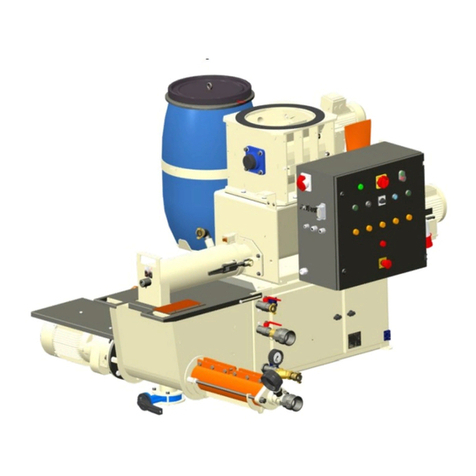

Installation and function ........................... 12

4.1

Overview............................................ 12

4.2

Overview............................................ 13

5

Module description.................................... 13

5.1

Mixing tube with material container... 13

5.2

Undercarriage with compressor and

control cabinet ................................... 14

6

Connections ............................................... 14

6.1

Connections of water and air............. 14

6.2

Connection of material hose.............. 14

7

Overview of control cabinet...................... 15

7.1

Modes, pressure boosting pump....... 15

8

Accessories................................................ 16

8.1

PFT - remixer for RITMO XL ............. 16

8.2

Covers ............................................... 16

8.3

Power cable / water-/air hose............ 16

9

Brief description ........................................ 17

10

Material ....................................................... 17

10.1

Flowability / conveying property.........17

11

Mortar pressure manometer......................17

12

Safety rules.................................................18

13

Transport, packing and storage................18

13.1

Safety instructions for transport .........18

13.2

Transport inspection...........................19

13.3

Transport in single parts.....................19

13.4

Transportation with crane...................20

14

Packaging....................................................21

15

Operation.....................................................22

15.1

Safety.................................................22

16

Preparation..................................................23

16.1

Connection of power supply...............23

16.2

Connection of water supply................24

16.3

Water from water barrel .....................24

17

Activation ....................................................25

17.1

Default of water flow volume..............25

18

Mortar pressure manometer......................26

19

Operating the machine ..............................26

19.1

Checking mortar consistency.............26

19.2

Machine "Flying start" ........................27

20

Mortar hoses...............................................27

20.1

Preparing mortar hoses......................27

20.2

Connecting mortar hose.....................27

21

Spraying gun...............................................28

21.1

Connecting spraying gun ...................28

21.2

Activating the air compressor.............28

22

Feeding machine with factory dry

material........................................................29

23

Applying mortar..........................................30

23.1

Opening air cock on the spraying

gun .....................................................30

23.2

Closing air cock..................................31

23.3

Work interruption................................31