3.MEASURINGTHICKNESS

3.1SoundVelocityCalibration

In order for the gauge to make accurate measurements, it must besettothecorrectsoundvelocityforthe

materialbeingmeasured.Differenttypesofmaterialhavedifferentinherentsoundvelocities.Ifthegaugeisnotsetto

thecorrectsoundvelocity,allofthemeasurementsthegaugemakeswillbeerroneousbysomefixedpercentage.The

One‐Pointcalibrationisthesimplestandmostcommonlyusedcalibrationprocedureoptimizinglinearityoverlarge

ranges. The Two‐pointcalibration allows for greater accuracy over small ranges by calculating the probe zero and

velocity.

Note:OneandTwopointcalibrationsmustbeperformedonmaterialwiththepaintorcoatingremoved.Failureto

removethepaintorcoatingpriortocalibrationwillresultinamultimaterialvelocitycalculationthatmaybedifferent

fromtheactualmaterialvelocityintendedtobemeasured.

Calibrationtoaknownthickness

Note:Thisprocedurerequiresasamplepieceofthespecificmaterialtobemeasuredwithaknownthickness

value.Thispartshouldbemeasuredwithacaliperormicrometer.

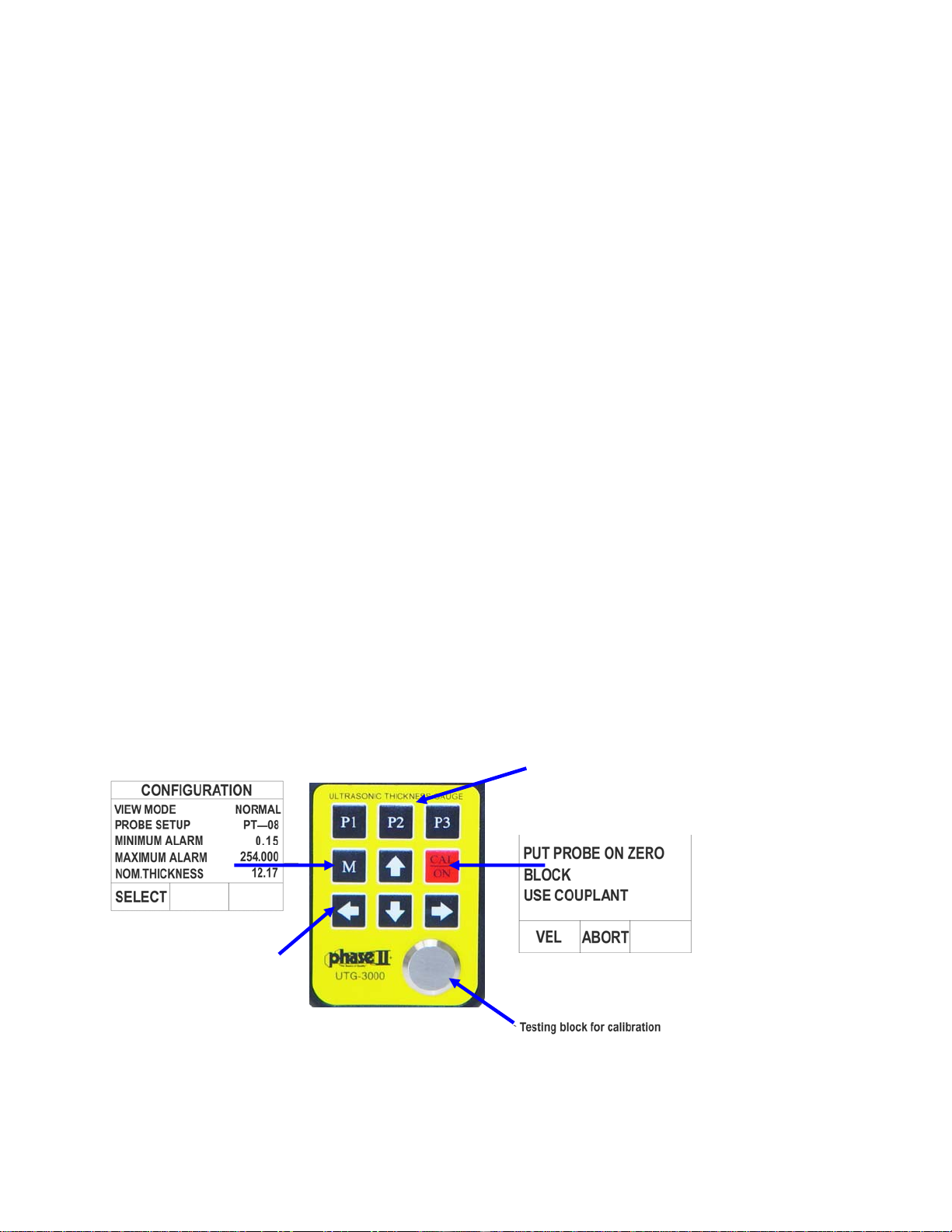

1) Performatestonthebuilt‐intestblocktoverifyunitisfunctioningproperly

2) Applycouplanttoyoursamplepiece.

3) Pressthetransduceragainstyoursamplepiece,makingsurethatthetransducersitsflatagainstthesurface

ofthesample.Thedisplayshouldshowa“whitecolored”thicknessvalue.

4) Havingachievedastablereading,removethetransducer.Ifthedisplayedthicknesschangesfromthevalue

shownwhilethetransducerwascoupled,repeatstep3.

5) PresstheCAL/ONbuttontoenterCalibrationmode.OnthebottomleftcornerofthedisplayitwillshowVEL.

PressthevirtualP1buttontoentervelocitysetting.

6) Pressthetransduceragainstthesamplepiece,makingsurethatthetransducersitsflatagainstthesurfaceof

thesample.ThedisplayshouldshowsomethicknessvalueintheTopLeftCornerasT=X.XXX.

7) Whileholdingtheprobeonyoursample,usethe4‐Arrowbuttonstochangethevelocityvalueuntilyousee

theT=theactualthicknessofyourpart.

8) PressP2(Done)buttontosavethesetting.

9) Youcannowbegintestingyourapplication(s)ofthissamematerial.

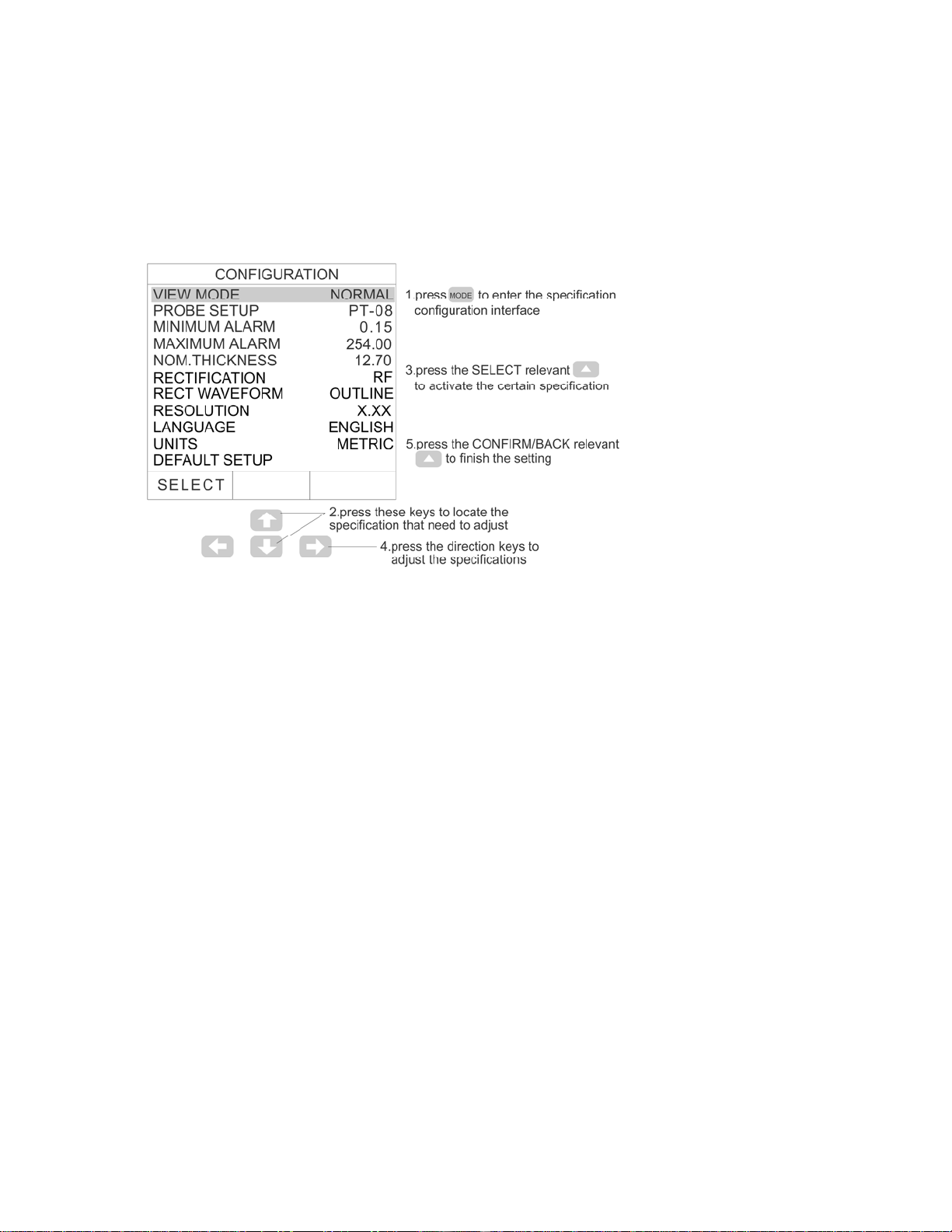

3.2.Adjustthevelocitydirectlyifthematerialvelocityisknown.Seeillustrationbelow.