CONTENT

1SRG-4500 OVERVIEW....................................................................................................

1.1 OUTLINE OF THE SRG-4500.........................................................................................................4

1.2 MEASUREMENT PRINCIPLE ..........................................................................................................4

1.3 FEATURES OF SRG-4500..............................................................................................................4

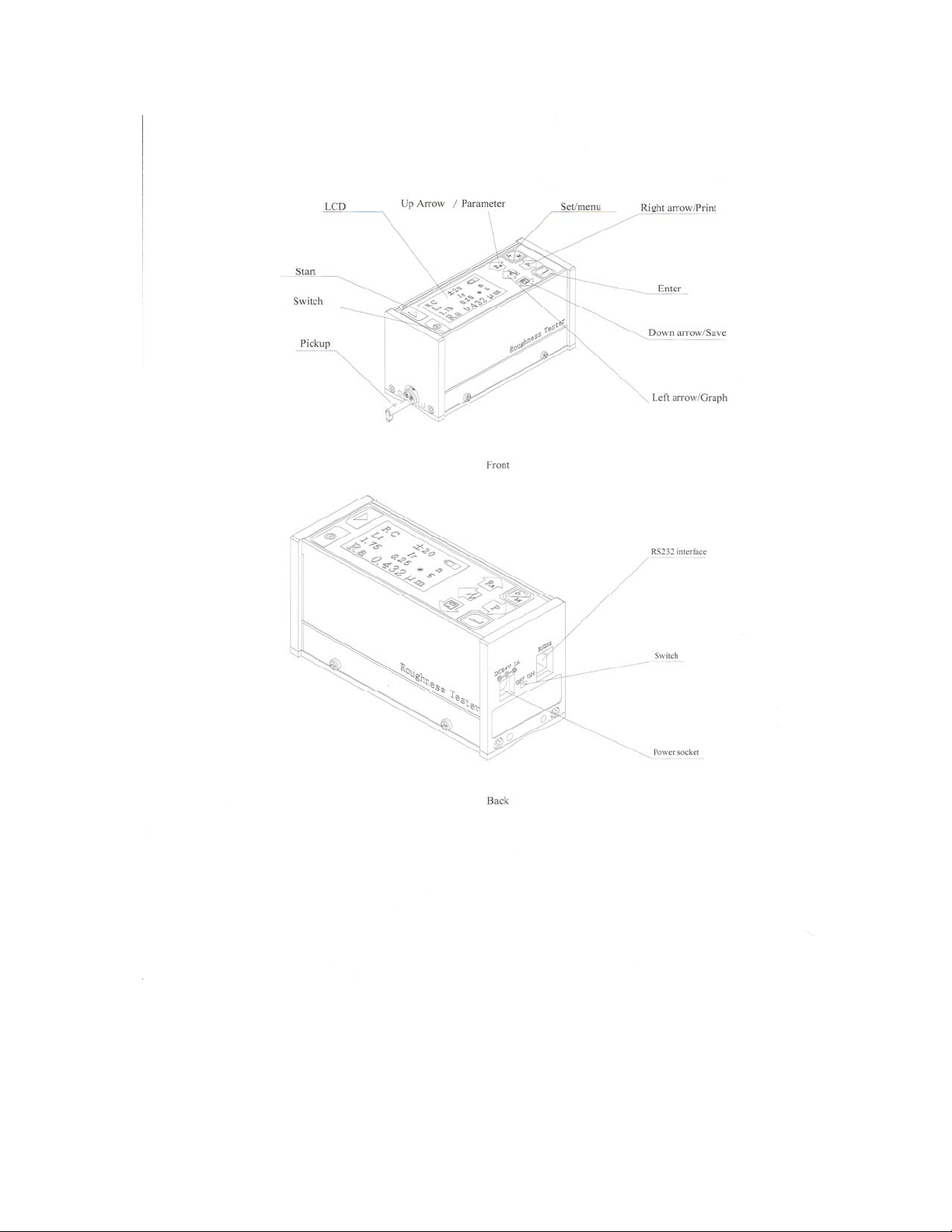

1.4 NOMENCLATURE..........................................................................................................................4

1.5 FUNCTION OF SHEET KEYS..........................................................................................................6

1.6 STANDARD CONFIGURATION .......................................................................................................7

1.7 BASIC CONNECTION ....................................................................................................................7

1.8 TURNING ON/OFF THE POWER SUPPLY .......................................................................................7

1.8.1 Turning On/Off Power button ................................................................................................7

1.8.2 Turning On/Off Battery switch..............................................Error! Bookmark not defined.

1.9 BATTERY CHARGING....................................................................................................................8

2SETTINGS SYSTEM INFORMATION..........................................................................................

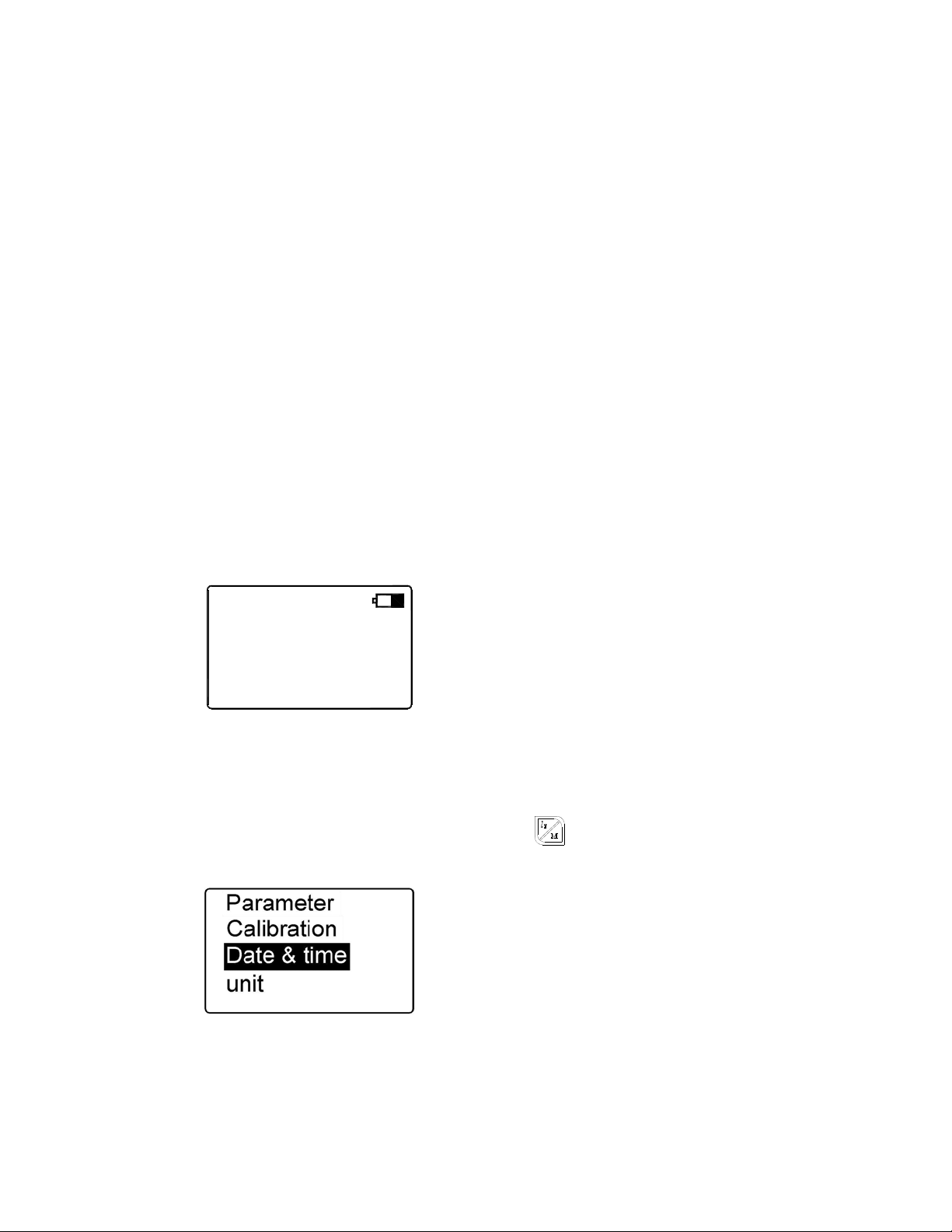

2.1 SETTING THE CLOCK .......................................................... ERROR!BOOKMARK NOT DEFINED.

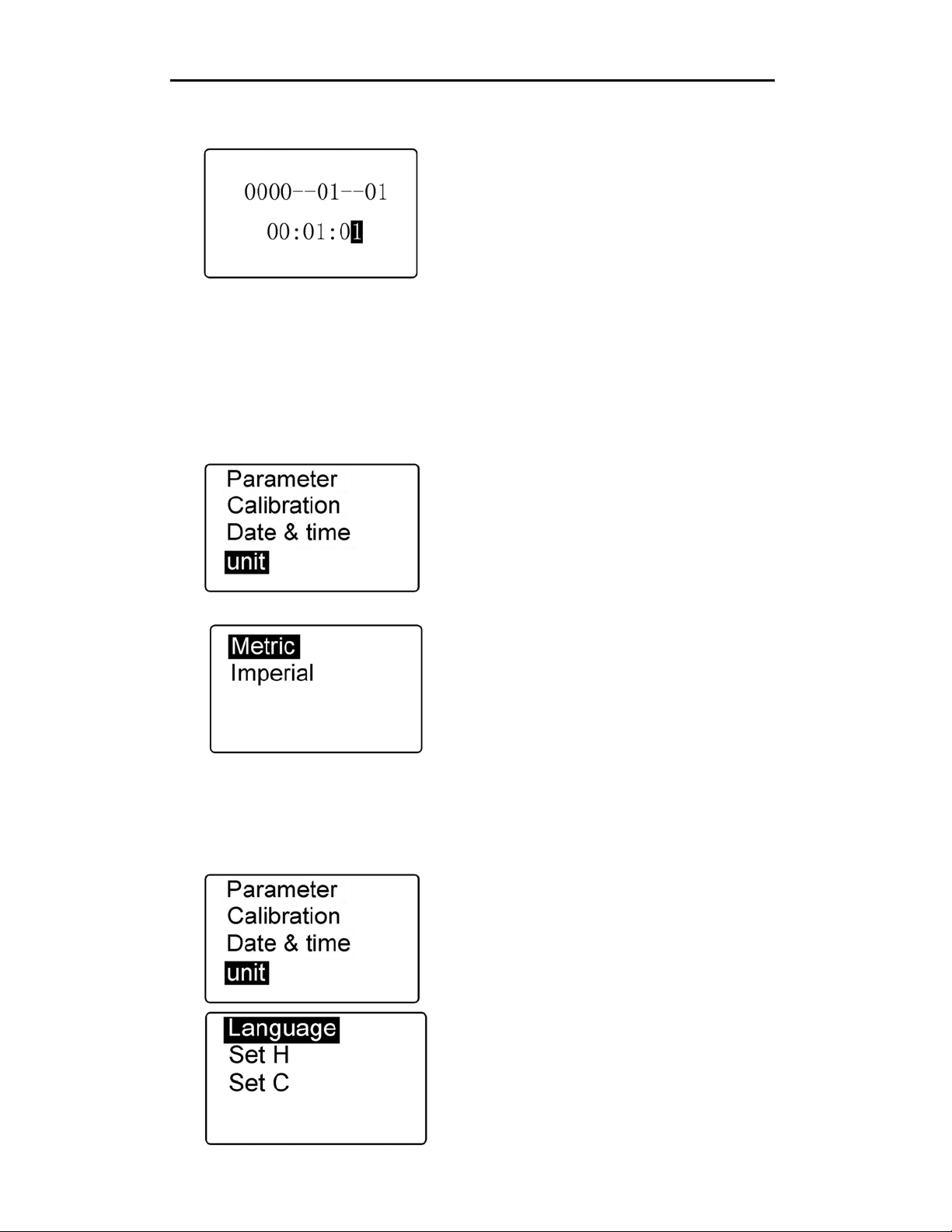

2.2 UNIT OF MEASUREMENT ..............................................................................................................9

2.3 SETTING LANGUAGE....................................................................................................................9

3MEASUREMENT OPERATION.................................................................................................

3.1 STYLUS POSITION.......................................................................................................................10

3.2 CALIBRATION.............................................................................................................................10

3.3 STARTING MEASUREMENT .........................................................................................................11

3.4 RESULTS DISPLAY ......................................................................................................................12

3.5 SAV E /READ MEASUREMENT RESULTS ......................................................................................13

3.6 PRINT MEASUREMENT RESULTS .................................................................................................14

3.7 DISPLAY MEASUREMENT RESULTS IN THE COMPUTER ...............................................................15

4SET MEASUREMENT CONDITIONS............................................................................................

4.1 MODIFY SAMPLING LENGTH ......................................................................................................15

4.2 MODIFY ASSESSMENT LENGTH.................................................................................................15

4.3 MODIFY FILTER ..........................................................................................................................15

4.4 MODIFY RANGE .........................................................................................................................16

4.5 MODIFY THE PARAMETERS OF MAIN INTERFACE.......................................................................16

4.6 MODIFY THE UNIT OF MEASUREMENT .......................................................................................16

4.7 SELECT PRINT PARAMETERS ......................................................................................................16

4.8 SETTING HVA L U E ......................................................................................................................16

4.9 SETTING CVA L U E ......................................................................................................................17

5MAINTENANCE ...........................................................................................................

5.1 PICKUP ........................................................................... ERROR!BOOKMARK NOT DEFINED.17

5.2 SRG-4500 ...................................................................... ERROR!BOOKMARK NOT DEFINED.17