7

2. INSTALLATION

Models are available in Type 1 indoor or Type 3R rain proof enclosures. The unit

should be securely mounted to a level surface and care taken to minimize the

introduction of dust and other contaminants into ventilation openings.

2.1 PHYSICAL INSTALLATION

Properly locating Phase Perfectis important to the performance and normal

operating life of the unit. The unit should be installed in a location free from:

Excessive dirt and dust

Corrosive gases or liquids

Excessive vibration

Airborne metallic particles

It is important that the unit be located away from excessive dirt and dust. Phase

Perfectshould be set on a clean, flat horizontal surface. Elevating the unit

above the ground will help to reduce the introduction of dust and contaminants

into the enclosure.

Models DPC-20 and DPC-30 are provided with lifting brackets inside the

enclosure. CABLES, STRAPS OR CHAINS USED FOR LIFTING THESE UNITS

MUST BE ATTACHED ONLY TO THE PROVIDED BRACKETS. Access the

brackets by removing the top cover of the enclosure. Brackets with a hole for

attaching lifting equipment are located on each side-wall of the enclosure.

In order to provide proper ventilation, do not obstruct the open space under and

around the enclosure. Make sure air intake and exhaust openings are not

obstructed. If the unit is mounted in a cabinet or shed, make certain there is

adequate ventilation to provide cooling for the unit.

2.2 ELECTRICAL INSTALLATION

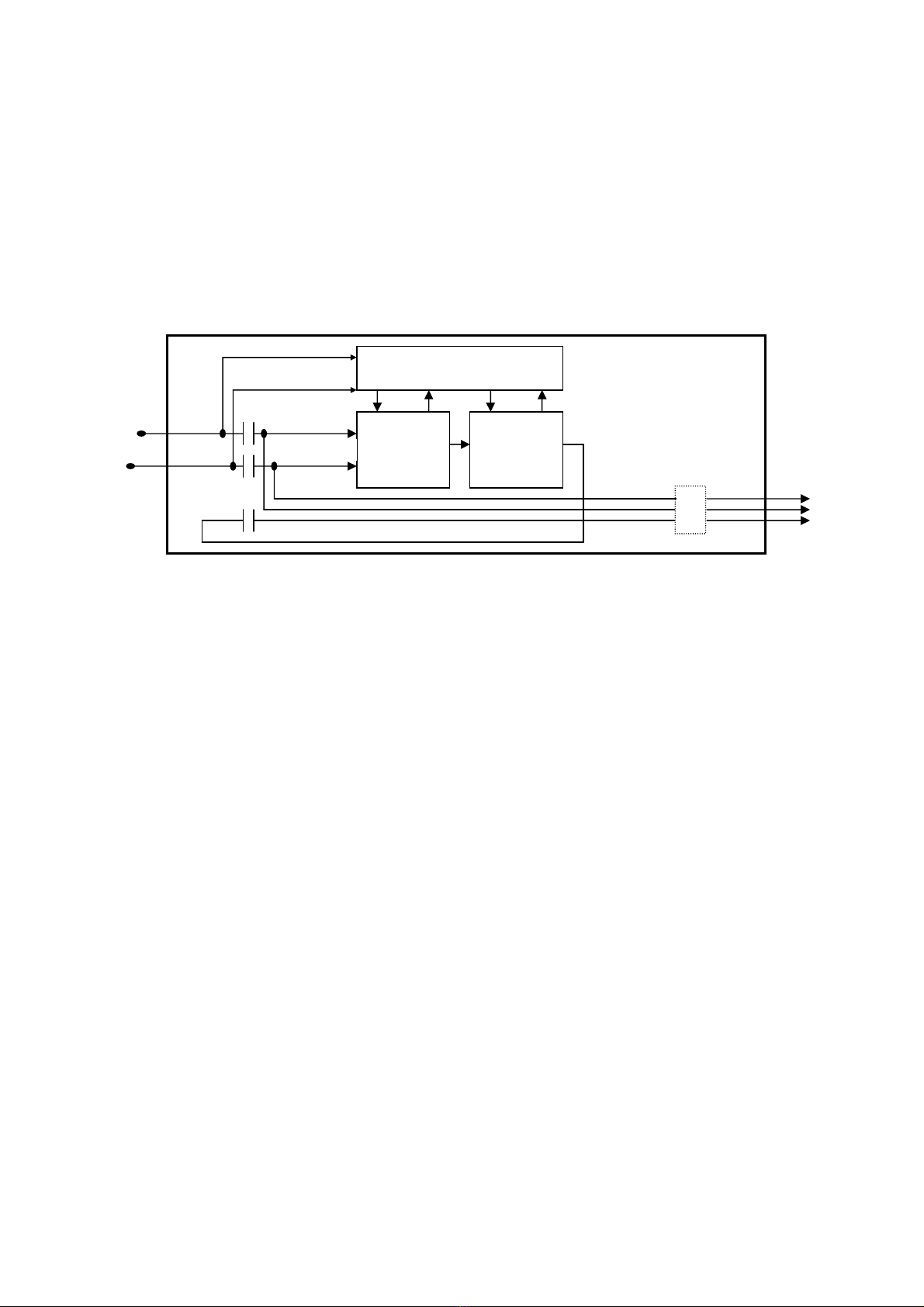

Electrical connections to the Phase Perfectare made behind the front panel of

the enclosure, as described in section 2.2.1. Phase Perfectis available

configured for use as a motor starter with single motor loads, or configured as a

power supply for multiple loads. These configurations are described in section

2.2.2.

Status lights provide information about the status of the Phase Perfectunit, and

about the entire system into which the unit is wired. The status lights are very

useful in troubleshooting system problems. Detailed information on the use of

the status lights for troubleshooting purposes is found in section 5.2.

A panel with terminal blocks for connecting wires is found behind the front panel.

Section 2.2.1 below illustrates the wiring connections and controls found on the

panel. Section 2.2.1.1 provides a description of general wiring considerations.

Section 2.2.1.2 provides diagrams of typical input power wiring configurations,

and discusses important considerations involved in input wiring from various

sources.