6CP100/50-10

3-2

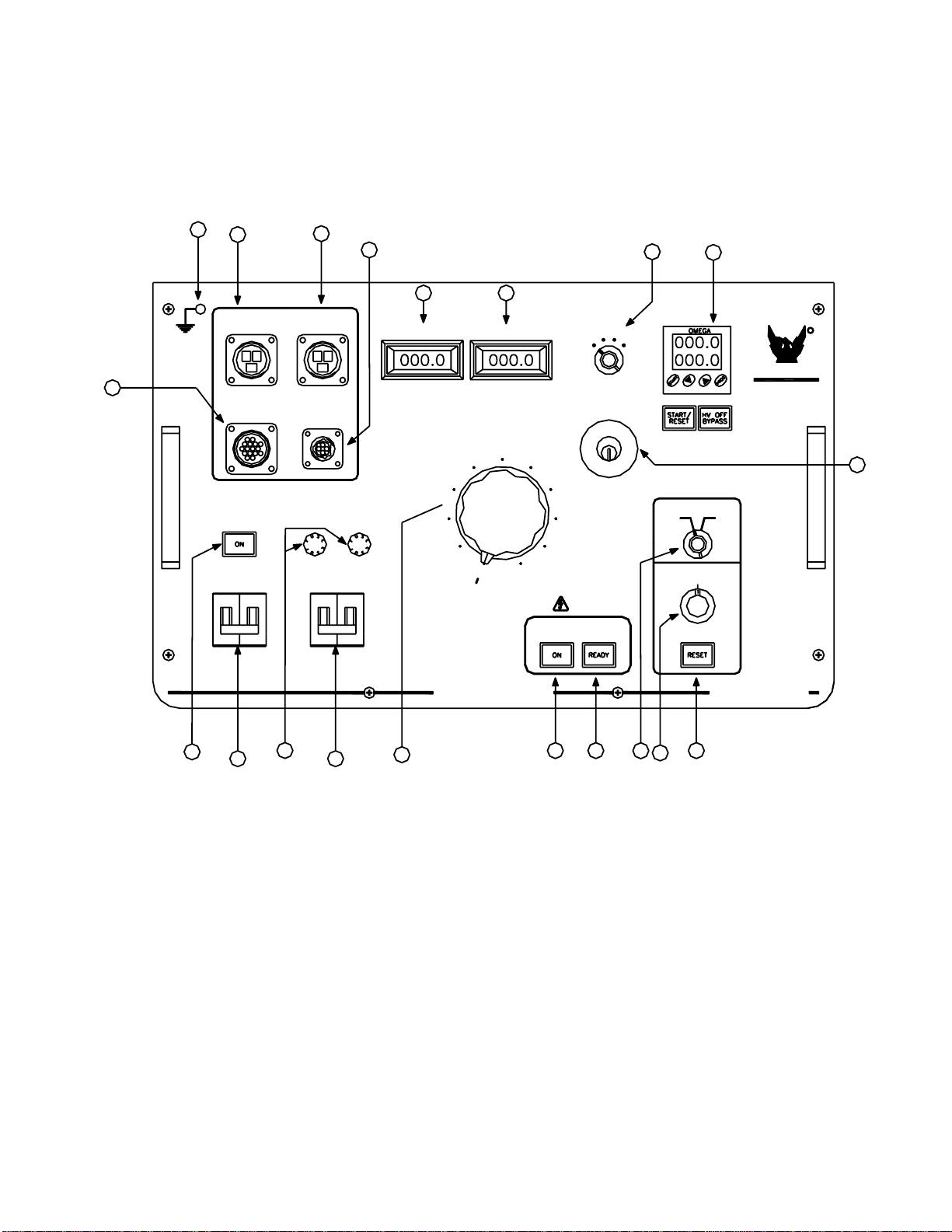

CONTROLS AND INDICATORS

Control Panel (Cont’d)

1. Reset

Will light when Overcurrent trip setting is exceeded. Push to reset. Lamp must be extinguished for

H.V. ON.

2. Emergency Off

Push down to stop test immediately. Button must be pulled up to activate High Voltage Output.

3. High Voltage On Switch and Indicator Lamp

Turns on H.V. when Ready indicator is illuminated.

4. High Voltage Off Switch and Indicator Lamp

Turns H.V. off, indicator shows when all conditions are met to turn H.V. ON. (External Interlock closed,

Reset Lamp off, Emergency Off Button pulled up, Voltage Control at Zero).

5. Voltage Control

Adjusts Output Voltage and must be set at zero to turn High Voltage on.

6. Currentmeter Range Selector

7. Output Currentmeter

8. Output Voltmeter

9. SX1 External Interlock

Provides for user connection of external interlock or auxiliary safety control device such as Emergency

Off Switch, Gate Switch, Footswitch, Dead man Switch, etc.

10. Output to Transformer

High Voltage Transformer power connection.

11. Main Input

Main input cable connects here.

12. Ground Terminal

13. TX1

Signal/ Metering cable between H.V. Unit and controls connects here.

14. Timer

Press START/RESET to start the timer after test voltage has been reached. Press START/RESET

again to reset timer to the original setting. Press HV OFF BYPASS to allow high voltage to remain on

after the timer has expired. Test time can be set using the buttons on the face of the timer.