Tank-Monitor VTM

REV 1A –FEB 2020 - Software Version 1.0 page 10

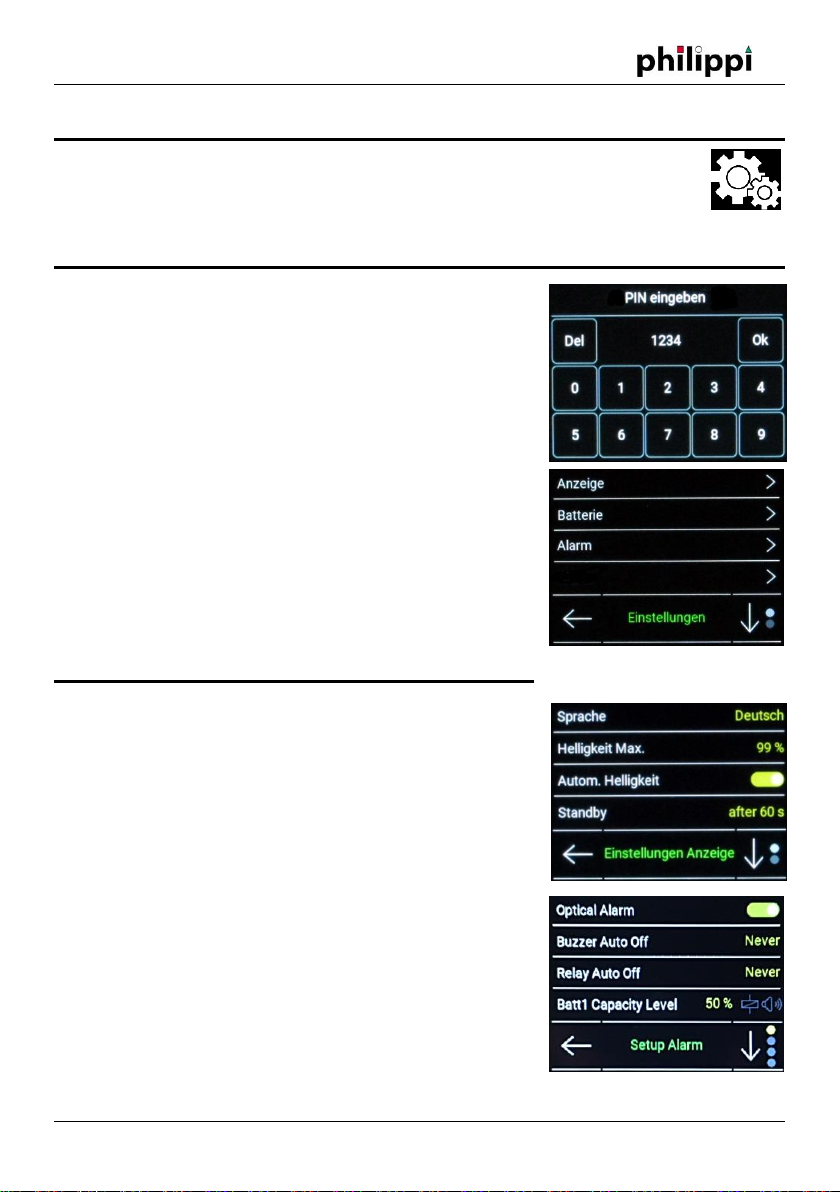

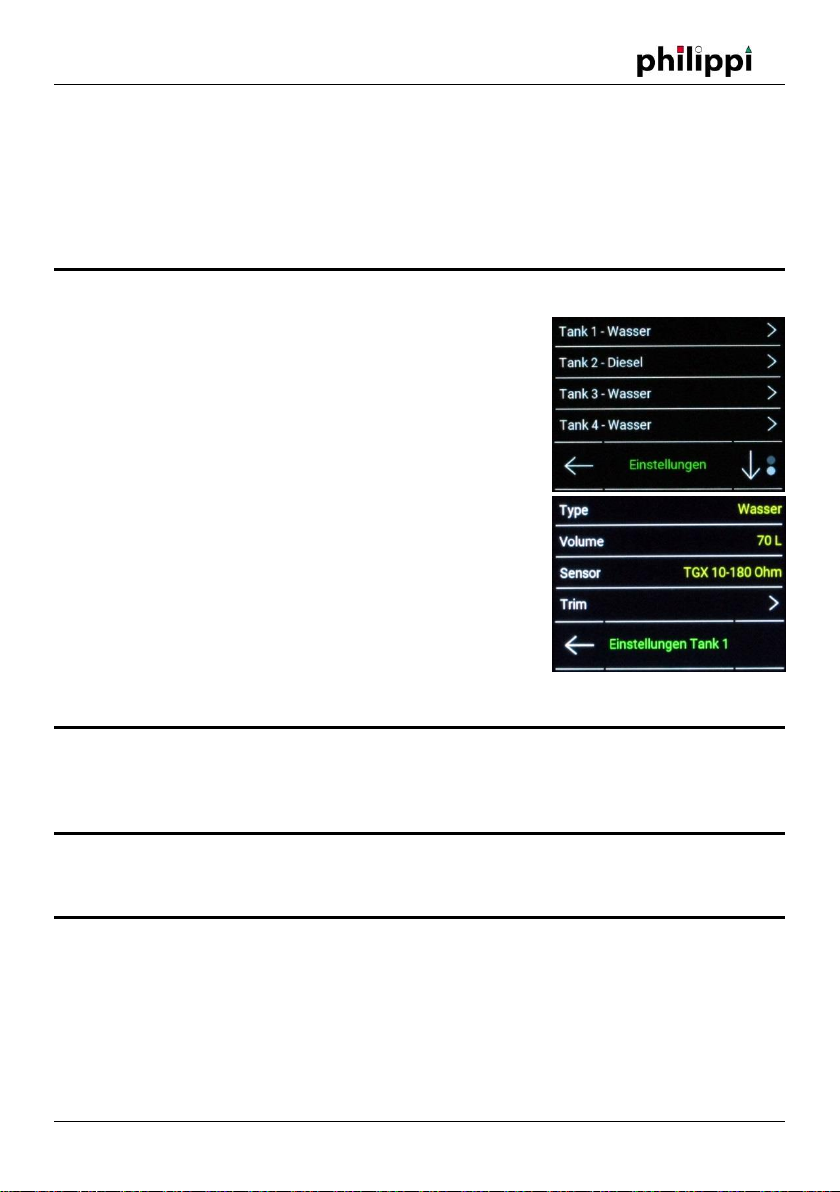

The tank depth can then be entered in the SETUP menu with centimeter precision for each tank.

After selecting the tank type UTV 40/80, the UTV type, the possibly spacer ring UTS and the tank

depth of the tank are entered in the submenu.

For tank depths incl. Spacer ring smaller than or equal to 40 cm, a UTV 40 is required; above a UTV

80. When using a UTV 40, the adjustable range is always below 40cm

Only UTV40 or UTV80 ultrasonic sensors may be used!

4.4.3.7 Sensor type TDS:

For this setting you will need a fuel gauge with a current output 4-20mA (for example TDS200,

TDN200, UTA). The calibration takes place in the menu TRIM, where the corresponding current

measured values can be entered or determined for the fill levels 0, 25, 50, 75 and 100%.

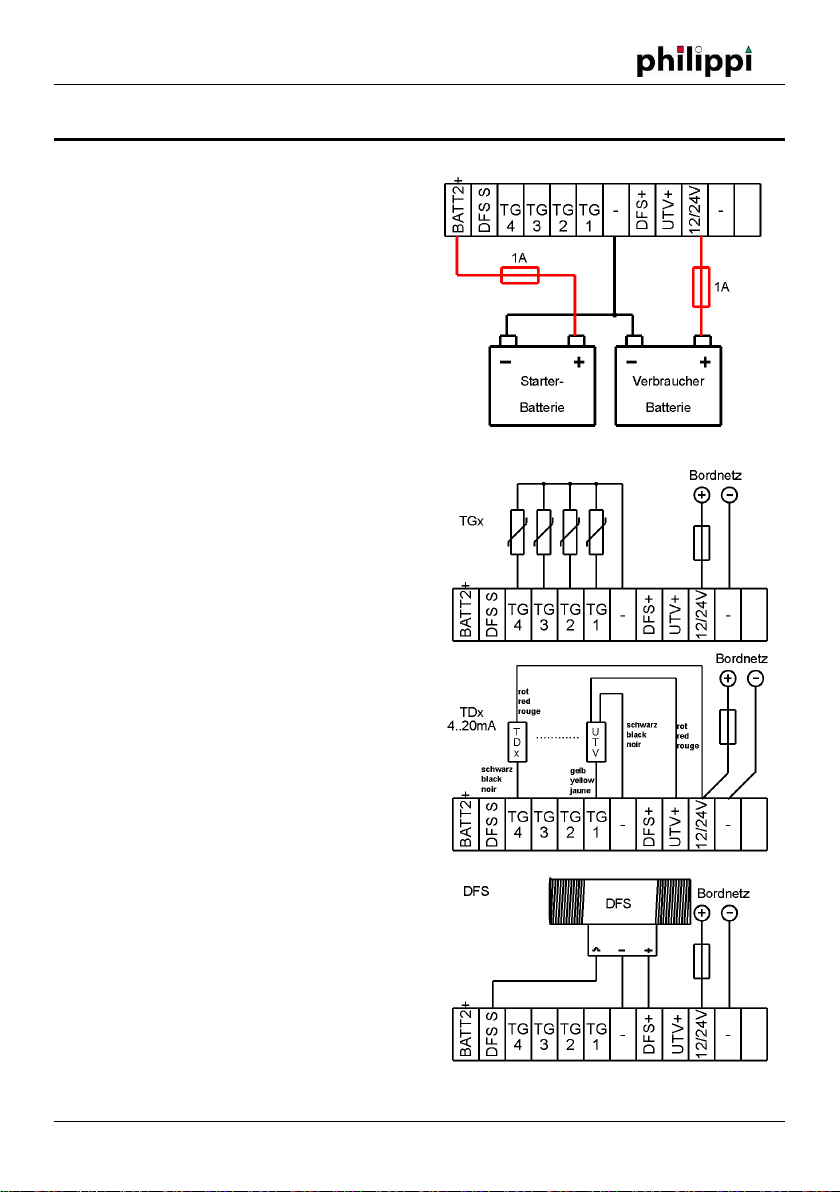

4.4.3.8 Sensor type DFS ↓

For this setting you need a flow sensor philippi DFS. The connection is only possible on DFS S. The

following symbol appears below the respective tank in the main menu:

Since this sensor can not detect whether the tank is being filled, you must enter the fill level

manually. By pressing the assigned key, you can go directly to the tank menu and adjust the level

accordingly. If water flows through the flow sensor DFS, this is indicated by the rotating symbol. The

DFS with arrow down empties the corresponding tank in the display.

4.4.3.9 Sensor type DFS ↑

See 4.6.3.8 - By contrast, the corresponding tank is filled with this setting. This is useful for detecting

the amount of fresh water produced when using a watermaker.

Only one DFS can be connected to the VTM

4.4.3.10 Sensor type TRS/RSW/DSW:

For this setting you need a philippi TRS float switch (mounting on top of the tank) or philippi RSW /

DSW (side mounting). The fuel gauge stays at 0% until the float switch goes through - the display

goes to 100%. There is no series resistor necessary!

4.4.3.11 Sensor type GOBIUS4

The voltage output of the Gobius control unit must be connected to a tank inlet. The level is

displayed in 4 steps. The internal settings of the Gobius system cannot be changed from the VTM.

They have to be adjusted via the Gobius panel.