Properties of the charging controller

108191_en_04 PHOENIX CONTACT 7 / 100

2 Properties of the charging controller

The EV Charge Control charging controller is used to control and monitor the charging of

electric vehicles on the AC power grid in mode 3 in accordance with IEC 61851-1. It is inte-

grated into a defined charging infrastructure which is permanently connected to the power

grid. It monitors the Control Pilot and Proximity Plug signals in accordance with

IEC 61851-1.

The charging controller is responsible for status-dependent control of the switching element

which is used to establish the connection between the power grid and the electric vehicle.

It is equipped with a residual current sensor that interrupts the charging process when re-

sidual DC currents occur.

The charging controller can be used to activate or deactivate the charging connector lock in

the charging station according to the status. It features a serial interface that can be used to

connect energy measuring devices and RFID card readers.

In addition, the charging controller is available in versions with Ethernet or 3G cellular inter-

faces. The charging controller can communicate with a central management system via an

OCPP interface (via OCPP 1.6J, JSON).

You can combine several charging controllers to create a master/slave group. This group

can communicate with the central management system via the master using the OCPP pro-

tocol.

Technical features

– Evaluation and control of the Control Pilot signal in accordance with IEC 61851-1

– Evaluation of the Proximity signal in accordance with IEC 61851-1

– Connection and disconnection of the charging current to the vehicle

– 6 mA DC/30 mA AC residual current detection and automatic shutdown in the event of

an error

– Activation of the charging connector lock and automatic release if voltage is interrupted

– RS-485 communication interface/Modbus/RTU (master) for connecting an energy

measuring device and RFID card reader

– Ethernet interface (Modbus/TCP) for configuration, remote control, and status requests

– OCPP connection (OCPP 1.6J, JSON) via cellular or Ethernet interface

– Master/slave group for connecting several charging controllers via one OCPP connec-

tion

– Integrated load management in the master/slave group to protect the infrastructure

against overload

– Maximum charging current that can be configured: 6 A … 80 A

– Optional monitoring of charging currents

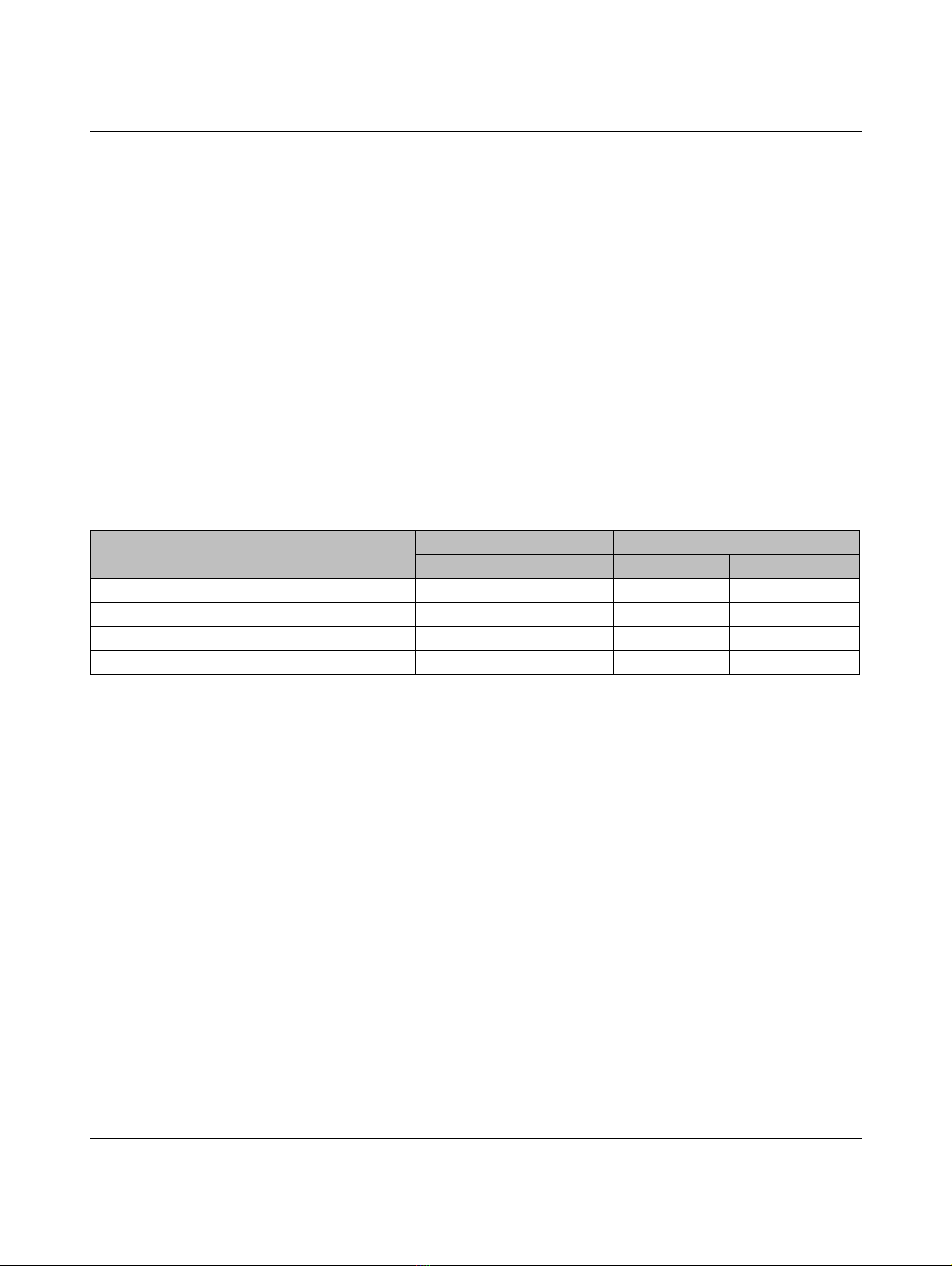

Table 2-1 Interfaces

Charging controller Communication OCPP 1.6J communication

Ethernet Cellular Ethernet Cellular

EV-CC-AC1-M3-CBC-RCM-ETH x – – –

EV-CC-AC1-M3-CBC-RCM-ETH-3G x x – x

EV-CC-AC1-M3-RCM-ETH-XP x – x –

EV-CC-AC1-M3-RCM-ETH-3G-XP x x x x