IM.EJB.X.01.2019 IECEx/ATEX Page 2

Contents

1.0 Safety Instructions ..........................................................................................................................2

1.1 Safety Notes....................................................................................................................................2

1.2 Modification and alteration............................................................................................................3

2.0 Standards conformity …………………………….......................................................................................3

3.0 Function ..........................................................................................................................................3

4.0 Technical Data.................................................................................................................................4

5.0 Installation.......................................................................................................................................6

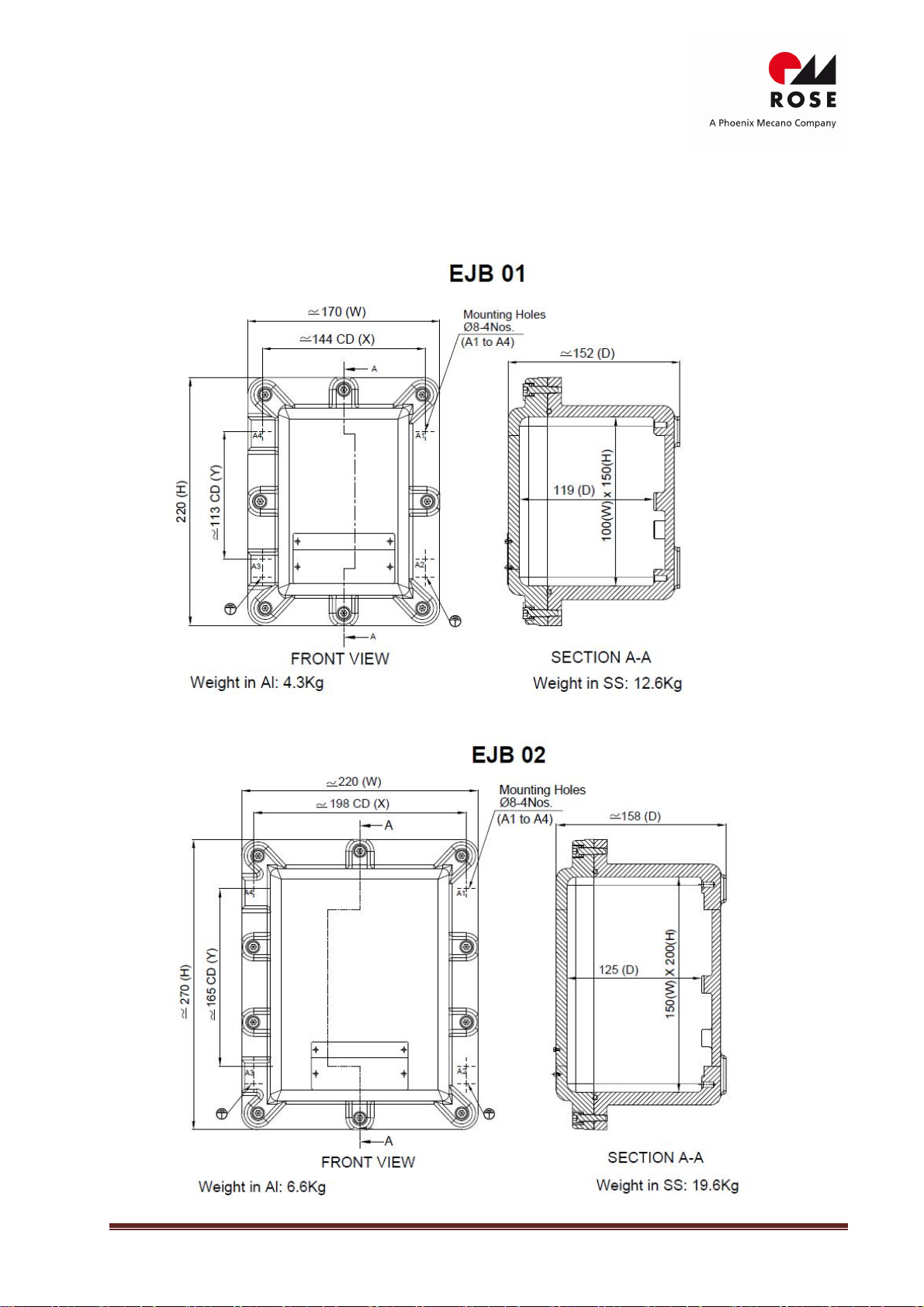

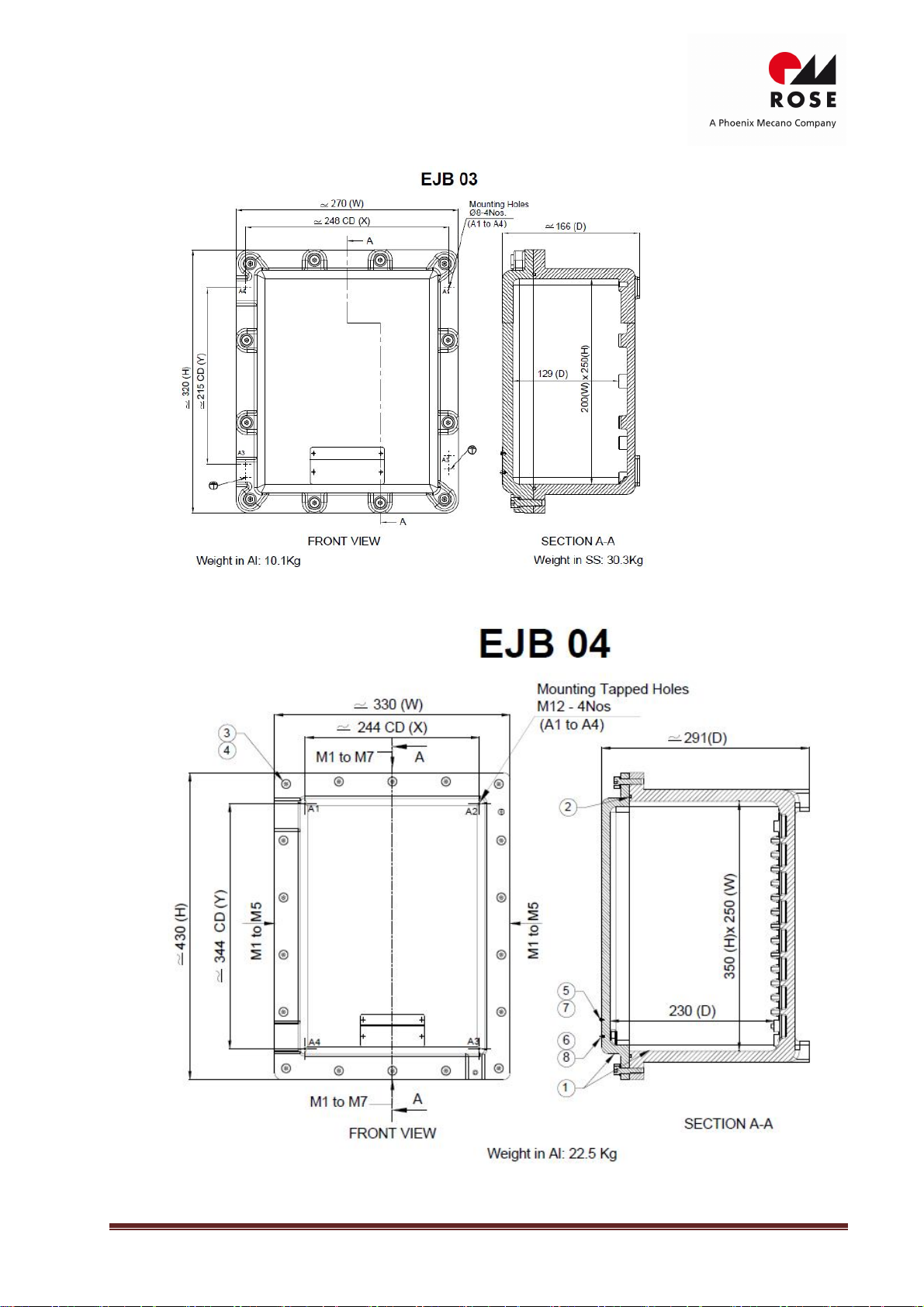

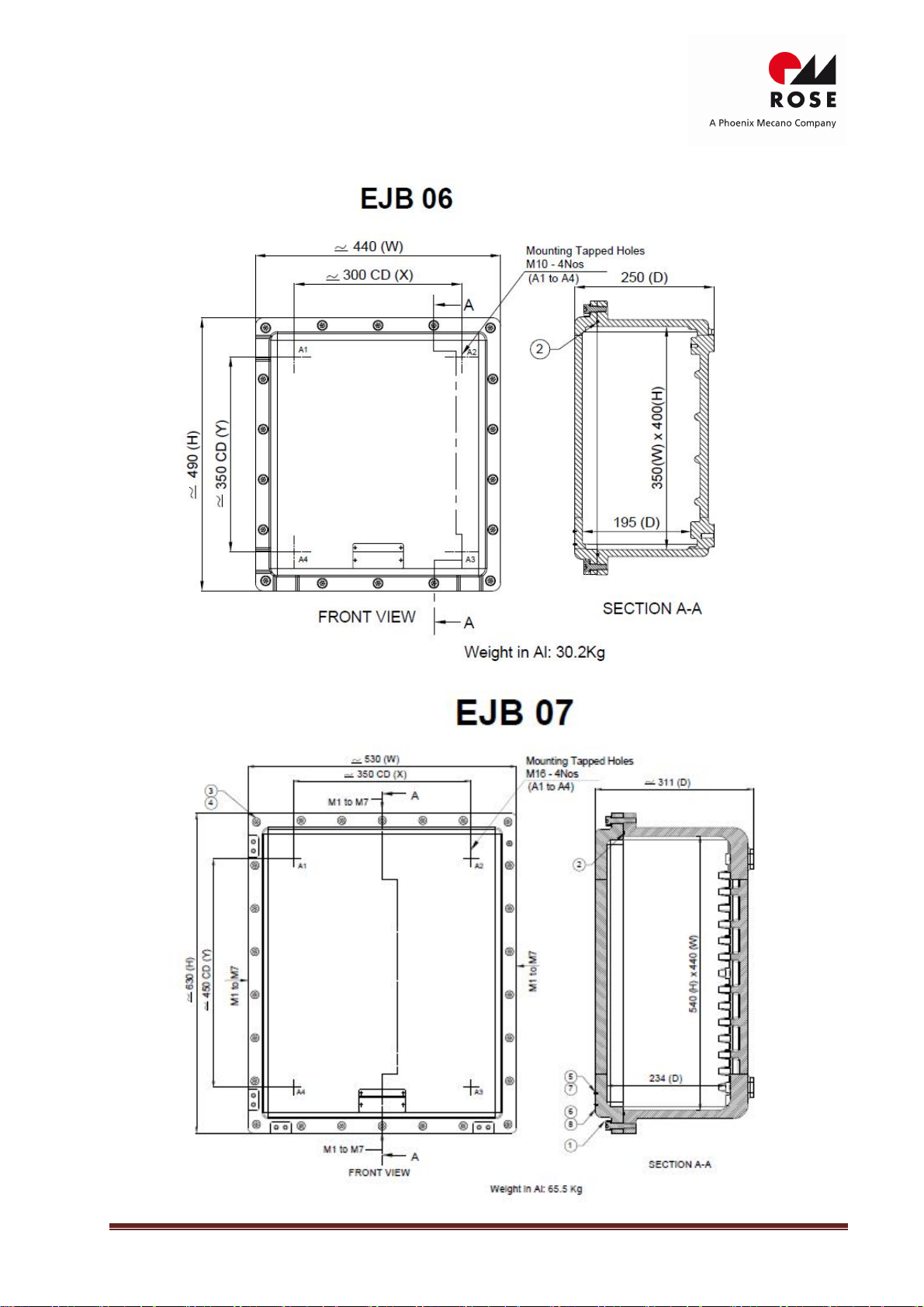

5.1 Dimensional drawings.....................................................................................................................6

5.2 Installation Conditions...................................................................................................................10

5.3 Mounting & operating positions....................................................................................................10

5.4 Electrical Connection.....................................................................................................................11

6.0 Commissioning ..............................................................................................................................12

7.0 Inspection, Maintenance, Overhaul and Repair.............................................................................12

7.1 Inspection and Maintenance .........................................................................................................12

7.2 Repair and Overhaul ......................................................................................................................12

8.0 Specific condition of use ................................................................................................................12

9.0 Technical Support………………………………………………………………………………………………………………………12

1.0 Safety Instructions

1.1 Safety notes

The target group of these instructions is electrical operatives and instructed staff

following EN/IEC 60079-14.

Operating permit expires in event of non-compliance.

Use the devices only for their intended purpose!

We cannotbe held liable for damage caused by incorrectorunauthorized

use or by non-compliance with these operating instructions.

Use the device only if it is undamaged.

Serious risk of injury!

Only original parts supplied by ROSE are permissible for spares and repair

work. Other spare parts can invalidate explosion protection.

The explosion group, temperature classand ambient temperature marked on the

enclosure must be observed!

Please look at marking on enclosure, it should be installed in zone, explosion

group, T Class & ambient temperature for which they are suitable.

We cannotbe held liable for damage caused by incorrectselection.

Any unauthorized work on the device is prohibited!

Installation, maintenance, overhaul and repair may only becarried out by

appropriately authorized and trained personnel.

Repairs affecting the explosion protection must onlybe carried out by ROSE or a

qualified authorized person in accordance with EN/IEC 60079-19!

Do not allow combustible dust deposit to form on enclosure!

Regular cleaning of dust deposit is recommended to avoid hot surface

becoming ignition risk.