8

DIVAL 600

EN Use, maintenance and warning instructions

MEDIUM PRESSURE REGULATOR |INTRODUCTION |REV. A

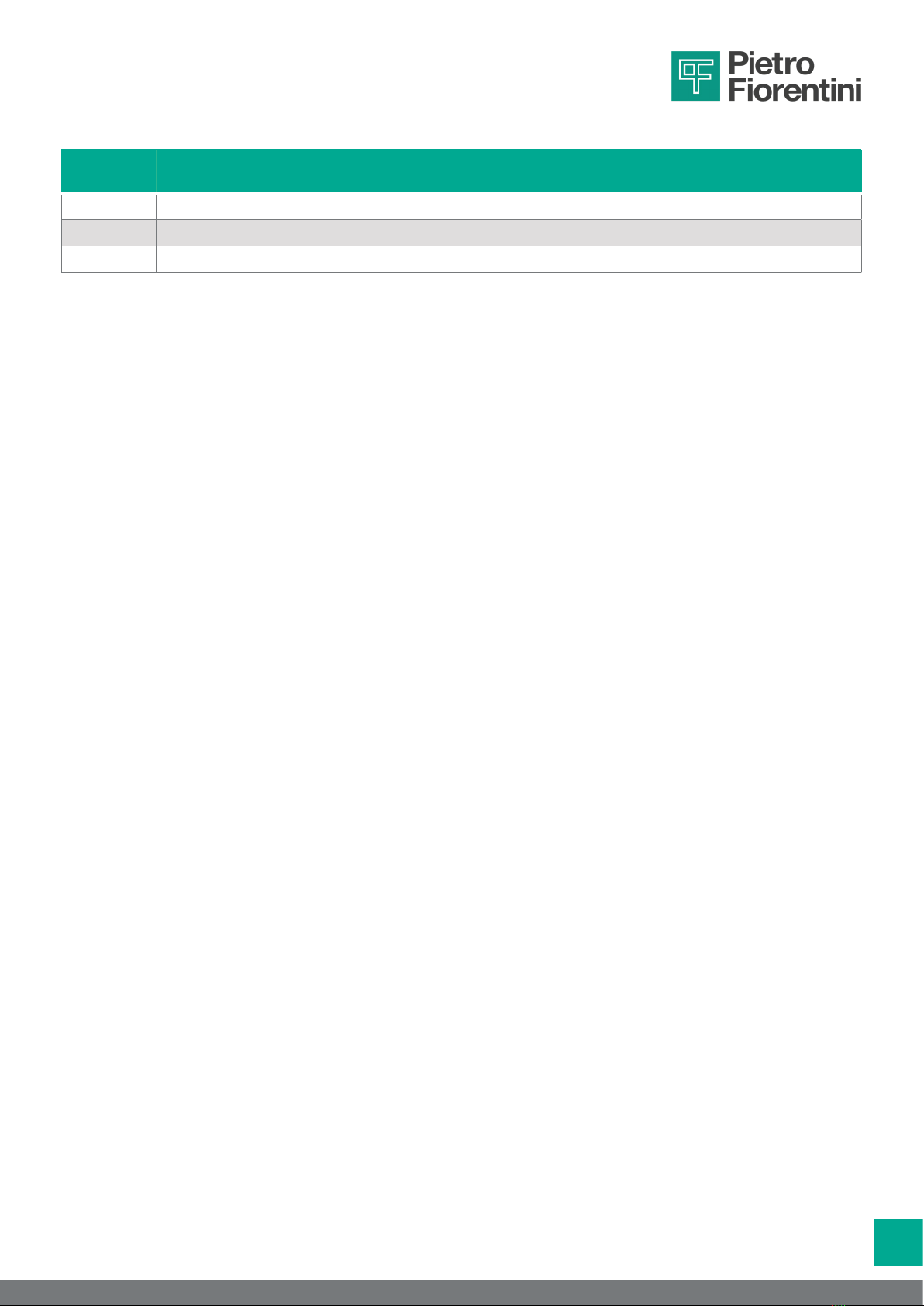

6 - INSTALLATION .................................................................................................................. 55

6.1 - INSTALLATION PRE-REQUISITES........................................................................................................... 55

6.1.1 - ALLOWED ENVIRONMENTAL CONDITIONS.........................................................................................55

6.1.2 - CHECKS BEFORE INSTALLATION........................................................................................................56

6.2 - SPECIFIC SAFETY INSTRUCTIONS FOR THE INSTALLATION STEP ...................................................... 57

6.3 - GENERAL INFORMATION ON CONNECTIONS ...................................................................................... 58

6.4 - REGULATOR INSTALLATION POSITIONS............................................................................................... 59

6.5 - INSTALLATION PROCEDURES .............................................................................................................. 60

6.5.1 - EQUIPMENT INSTALLATION PROCEDURES ........................................................................................60

6.5.2 - CONNECTION OF THE SENSING LINES TO THE DOWNSTREAM PIPING...........................................60

6.6 - POST-INSTALLATION AND PRE-COMMISSIONING CHECKS ................................................................ 62

7 - COMMISSIONING/MAINTENANCE EQUIPMENT........................................................... 63

7.1 - LIST OF EQUIPMENT.............................................................................................................................. 63

7.2 - EQUIPMENT NEEDED FOR THE DIFFERENT CONFIGURATIONS .......................................................... 65

8 - COMMISSIONING ............................................................................................................. 67

8.1 - GENERAL WARNINGS ........................................................................................................................... 67

8.1.1 - SAFETY REQUIREMENTS FOR COMMISSIONING ...............................................................................67

8.2 - PRELIMINARY PROCEDURES FOR COMMISSIONING .......................................................................... 68

8.3 - PROPER COMMISSIONING CHECK ...................................................................................................... 69

8.4 - CALIBRATION OF EQUIPMENT AND ACCESSORIES INSTALLED.......................................................... 69

8.5 - REGULATOR COMMISSIONING PROCEDURE ..................................................................................... 70

8.6 - COMMISSIONING PROCEDURE OF REGULATION LINE: DIVAL 600 REGULATOR + DIVAL 600 REGULA-

TOR WITH IN LINE MONITOR FUNCTION .............................................................................................. 72

8.6.1 - PRESSURISING WITH EXTERNAL SOURCE.........................................................................................76

8.7 - COMMISSIONING PROCEDURE OF DIVAL 600 REGULATOR WITH LA SLAM-SHUT VALVE................. 78

8.7.1 - INTERNAL TIGHTNESS CHECK OF LA SLAM-SHUT VALVE.................................................................78

8.7.2 - COMMISSIONING OF THE DIVAL 600 REGULATOR WITH LA SLAM-SHUT VALVE..............................79

8.7.3 - PROCEDURE FOR CALIBRATING THE PRESSURE SWITCH FOR THE LA INCORPORATED SLAM-

SHUT VALVE .........................................................................................................................................82

8.8 - COMMISSIONING PROCEDURE OF REGULATION LINE: DIVAL 600 REGULATOR + DIVAL 600 REGULA-

TOR WITH IN LINE MONITOR + LA SLAM-SHUT VALVE FUNCTION

............................................................................................................................................................... 86

8.9 - DEVICE CALIBRATION............................................................................................................................ 90

8.9.1 - PRESSURE SWITCH CALIBRATION FOR THE LA SLAM-SHUT VALVE ...............................................90