Contents

1Warnings / Notes .......................................................................................................................................3

2Specifications .............................................................................................................................................4

3Software Manual........................................................................................................................................5

3.1 Main Window......................................................................................................................................5

3.1.1 Overview ......................................................................................................................................5

3.1.2 Status ...........................................................................................................................................6

3.2 Plot Windows ......................................................................................................................................6

3.2.1 Graph Scale ..................................................................................................................................6

3.2.2 Legend Position............................................................................................................................7

3.2.3 Exporting Graph Data...................................................................................................................7

3.2.4 Notes on Graph Functions ...........................................................................................................7

3.3 Manual Control Mode.........................................................................................................................7

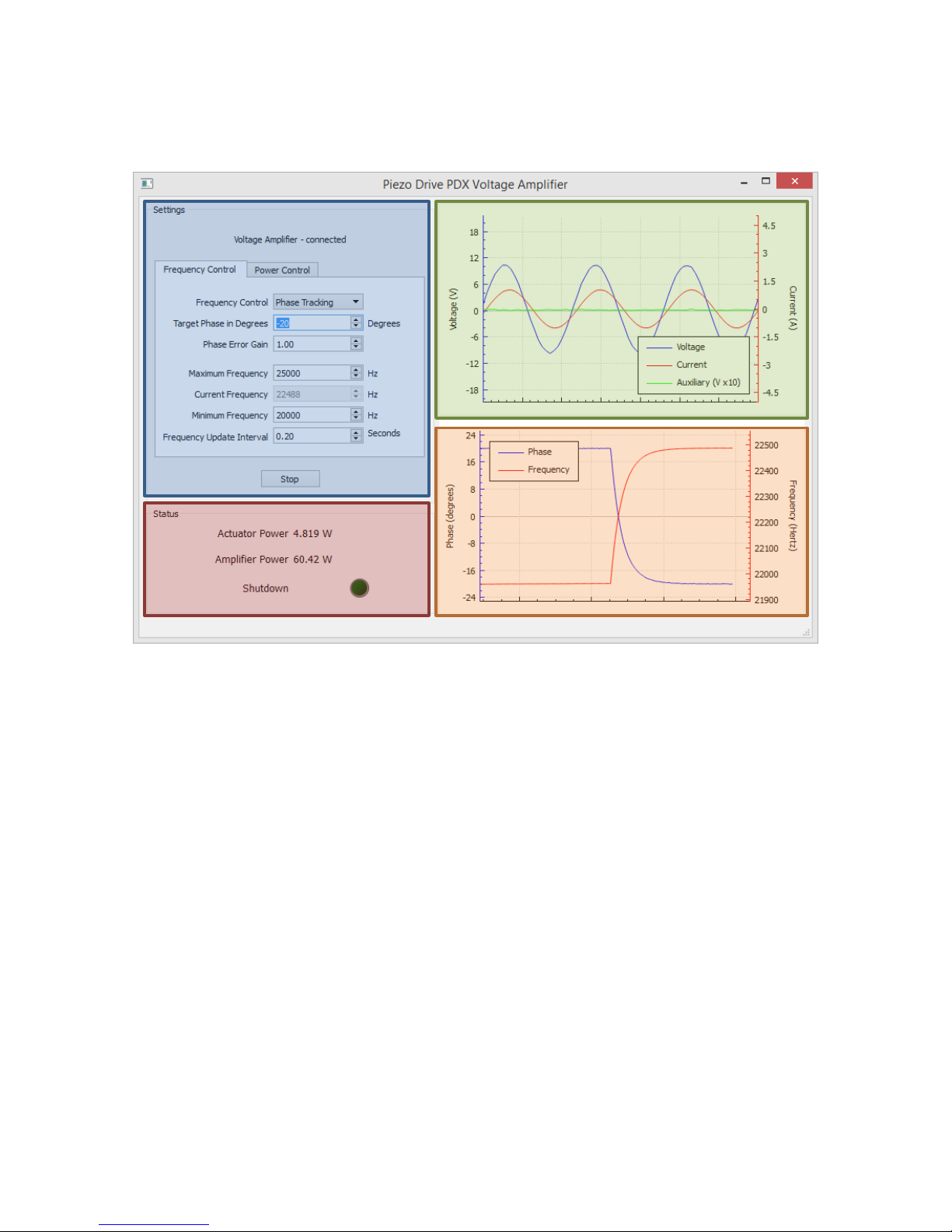

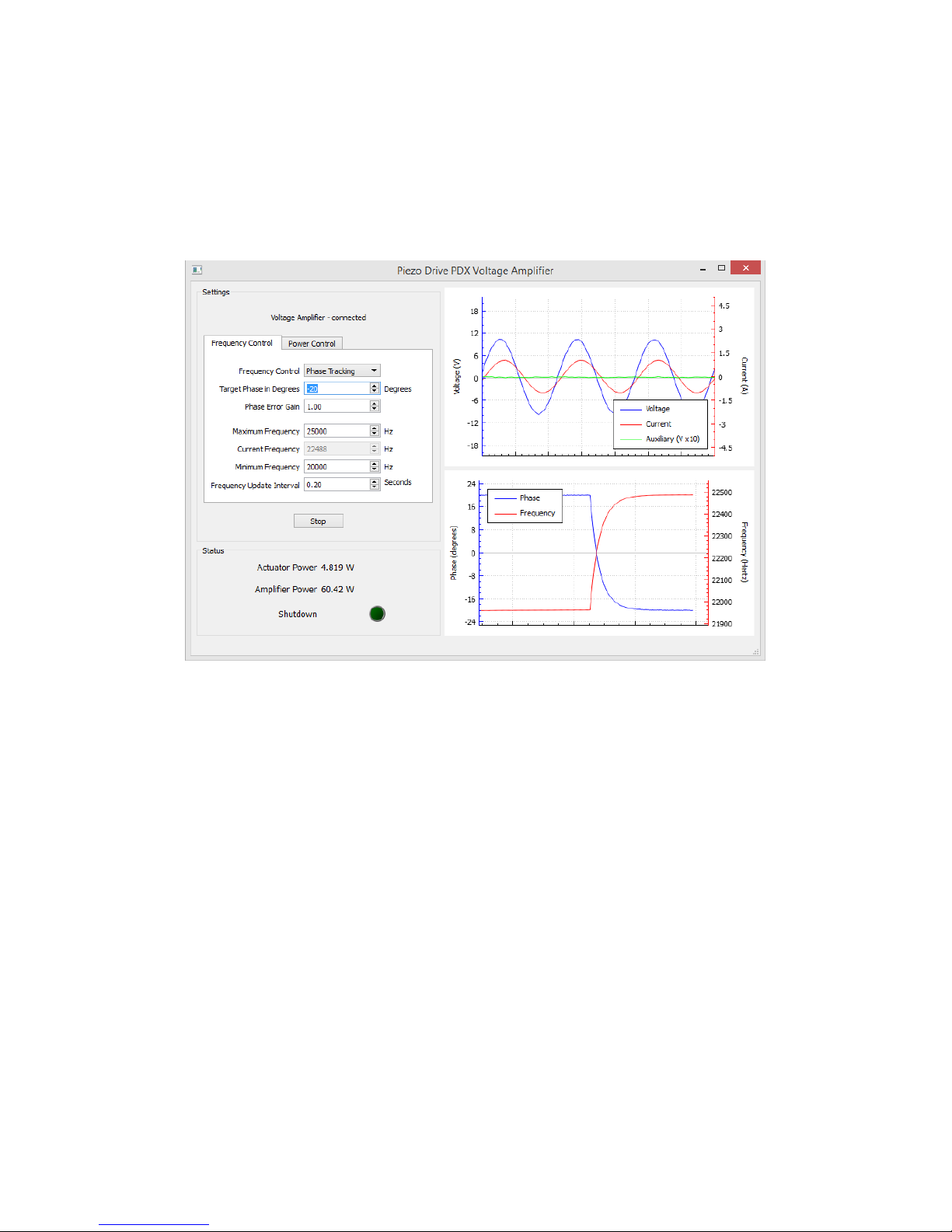

3.4 Resonance Tracking Mode (Phase Tracking).......................................................................................8

3.5 Resonance Tracking Mode with Power Control..................................................................................9

3.6 Frequency Sweep Mode....................................................................................................................10

3.6.1 Dynamic Range ..........................................................................................................................11

4Hardware Manual ....................................................................................................................................12

4.1 Output Connection Diagram .............................................................................................................12

4.1.1 LEMO Plug Cable Preparation....................................................................................................13

4.1.2 LEMO Plug Assembly..................................................................................................................13

4.2 Overload Protection..........................................................................................................................14

4.2.1 Shutdown Indicator ...................................................................................................................14

4.2.2 External Shutdown.....................................................................................................................14

4.2.3 Enclosure....................................................................................................................................14

5Installation ...............................................................................................................................................15

6API Functions ...........................................................................................................................................15