TD250 V8 Manual 2 Rev 2, 31-09-2020

Contents

1Introduction..................................................................................................................................... 3

2Warnings / Notes............................................................................................................................. 3

3Specifications................................................................................................................................... 4

4Delivery Contents ............................................................................................................................ 4

5Channel Configurations ................................................................................................................... 5

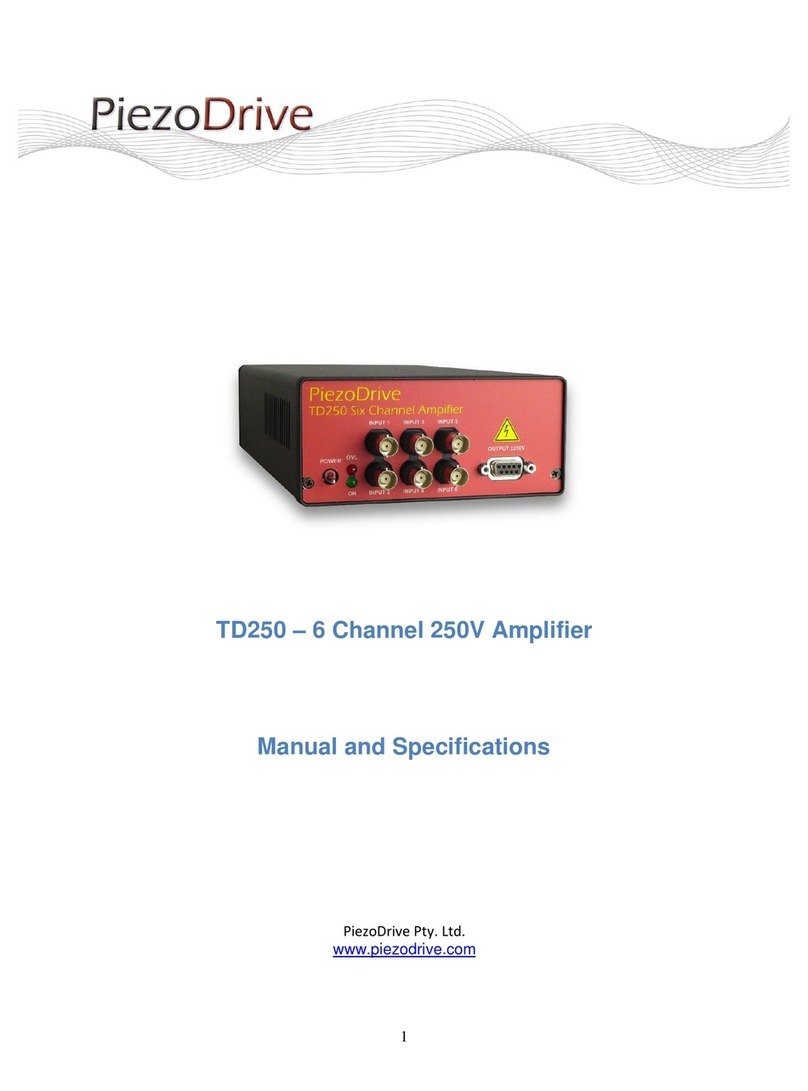

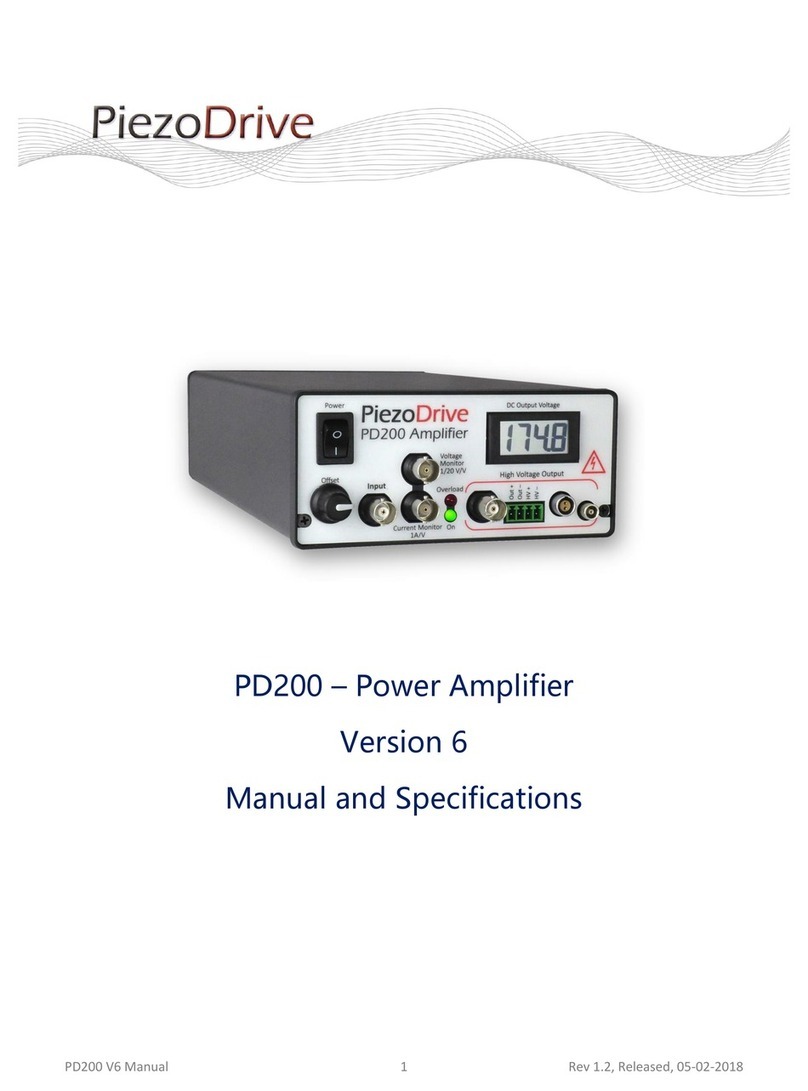

6Front Panel ...................................................................................................................................... 6

7Rear Panel........................................................................................................................................ 7

8Grounding and Earthing .................................................................................................................. 7

9Breakout Box ................................................................................................................................... 8

10 Power Bandwidth ......................................................................................................................... 9

11 Pulse Currents............................................................................................................................... 9

12 Small Signal Frequency Response ............................................................................................... 10

13 Noise........................................................................................................................................... 11

13.1 Noise Spectral Density ......................................................................................................... 11

13.2 RMS Noise............................................................................................................................ 12

13.3 Typical Noise Waveforms..................................................................................................... 12

13.4 Noise Test Conditions........................................................................................................... 13

14 Overload Protection.................................................................................................................... 13

14.1 Status Signal......................................................................................................................... 13

14.2 Disable Command ................................................................................................................ 13

15 Driving Piezoelectric Tubes......................................................................................................... 14

16 Bridged Load Configuration ........................................................................................................ 16

17 Warranty..................................................................................................................................... 16