2

Features

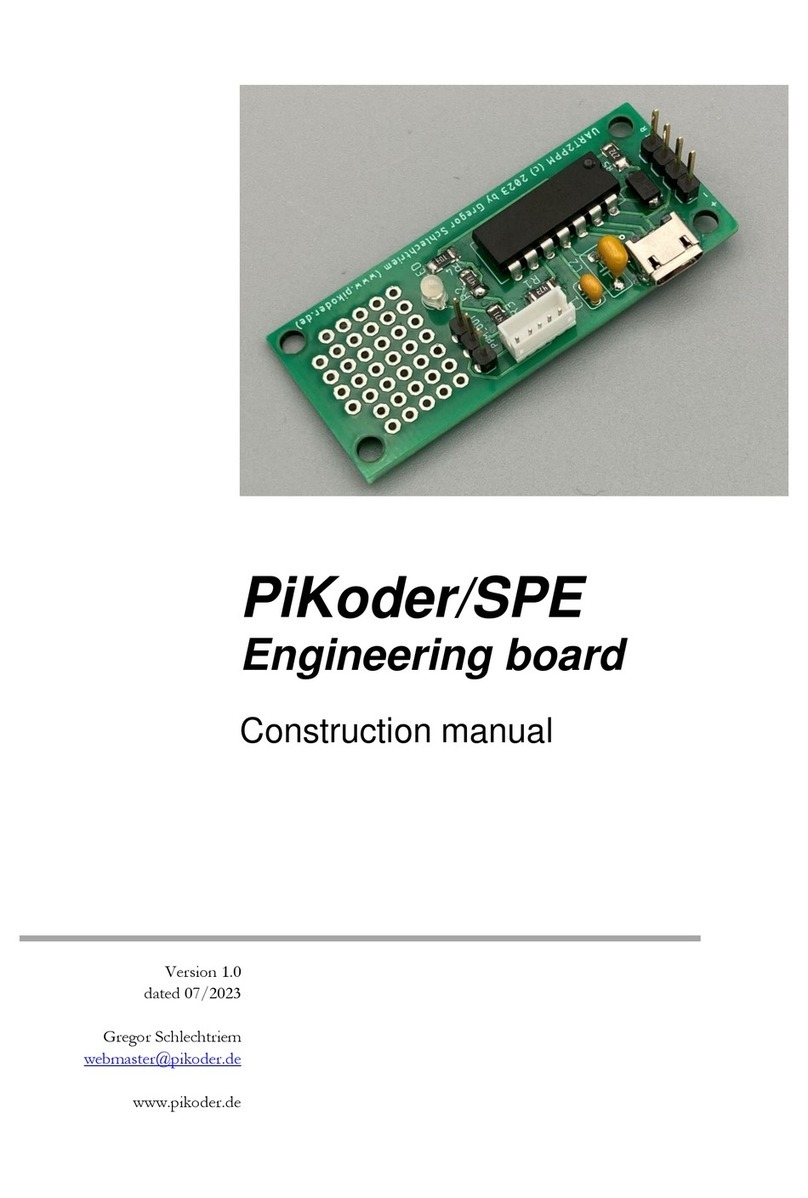

This section will familiarize you with the feature set and provide a high-level

overview of the intended use of the PiKoder/SPE allowing you to customize

the controller to your specific needs and requirements.

The PiKoder/SPE generates a PPM stream which is controlled by a com-

mand protocol via a UART port. More specific, the PiKoder/SPE features a

two-way ASCII-Protocol designed to be used in combination with standard

terminal programs such as (but not limited to) Tera Term and TTY.

In addition, various application specific parameters such as startup position

after powering up, failsafe value per channel, PPM polarity, the number of

channels and the baud rate of the UART can be adjusted to your specific

needs and the settings are maintained in a non-volatile memory.

You can connect an SBC (Single Board Computer) such as your Arduino or

Raspberry Pi without any additional interface hardware directly to the

PiKoder’s UART (please refer to sections 7 and 8 for more details). In this

capacity the PiKoder would free up the Arduino or Raspberry Pi of respond-

ing to real-time events such as generating pulses within “real-time” and thus

free up resources such as internal timers and PWM generators ('Set and For-

get'-function).

You would program the PiKoder/SPE by connecting it with a standard USB

cable to your computer. A free graphical and intuitive configuration and con-

trol program, the “PCC G2 (PiKoder Control Center Generation 2)” is avail-

able for Windows 10, making it simple to test and program the controller

over USB (please refer to section 5 for more details). All settings are stored

in a non-volatile memory.

The PiKoder/SPE does support a failsafe position for the use in autonomous

and RC applications. You can activate a watchdog-timer for 0.1 s to 99.9 s to