MACHINE SPECIFICATIONS

Model: H49

Voltage: 220 VAC 3 Phase

60 Hz 12 Amp

Air: 90 psi @ 20 CFM

Dust Collecon: 350 CFM

MATERIAL RESTRICTIONS

Work Piece Length………………………... Up to 49"

Work Piece Width…………………..….… Unlimited

Work Piece Thickness……….……....... Up to 1”

DRIVES

X Axis - Rack and inion

Y Axis - Mechanical by use of Digital Readou

Z Axis - Mechanical by use of Digital Readou

MACHINE DIMENSIONS

Length - 78” Depth - 52” Height - 76”

Weight 1400 lbs. (approximae)

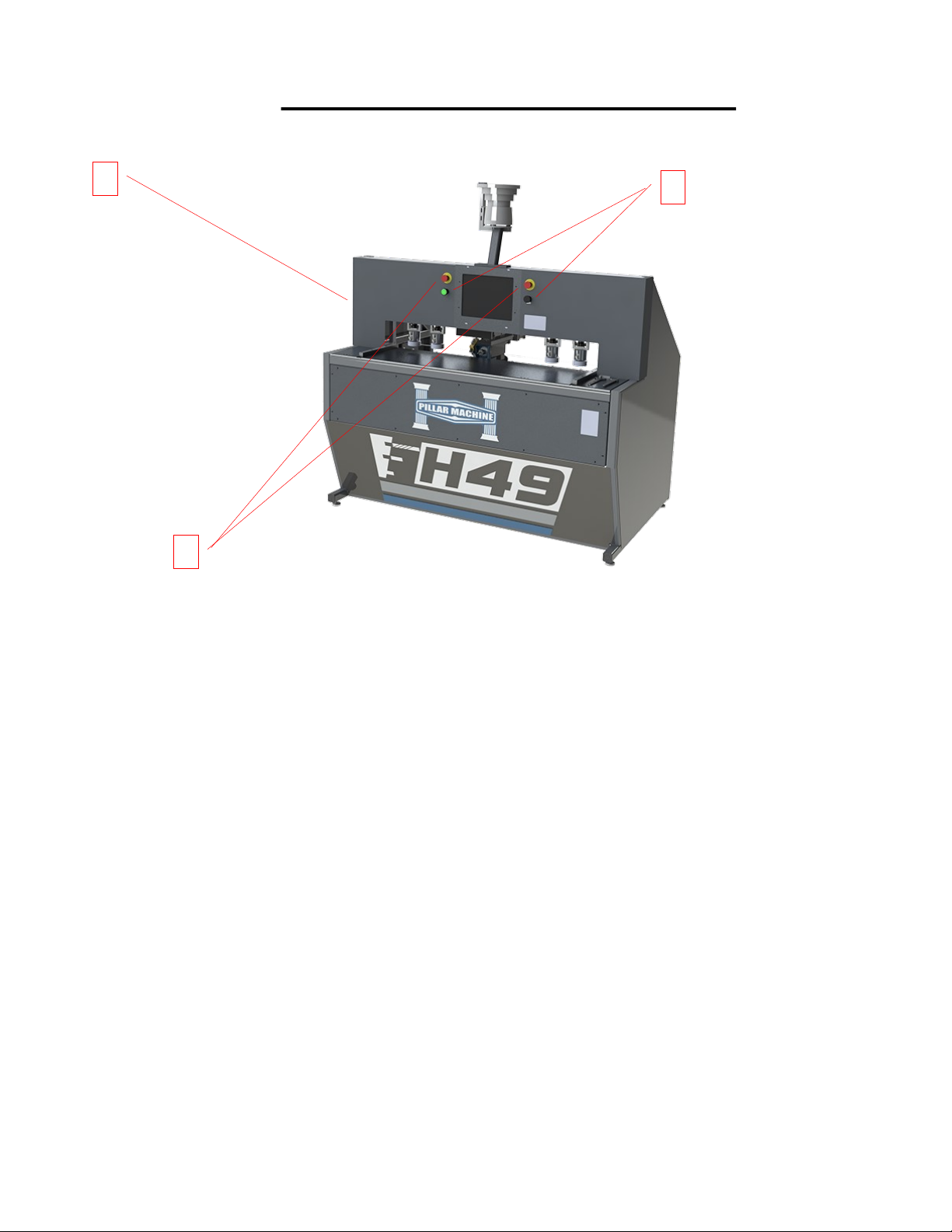

H-49 CNC HORIZONTAL POINT TO POINT MACHINING CNR

The model H-49 is a horizontal point to point bore and dowel inseron machining center. It is designed to CNC posion the spindle, bore a hole,

then CNC posion the inserter, inject glue or water (for pre glued dowels), and re the dowel into the hole. A part is placed into the work zone

referencing the back and side fences. The green palm buon is pressed and the clamps secure the part into place. The machining is now ready

to begin in the work zone. There are 2 zones standard in the base model H-49 allowing for pendulum processing. While the one part is being

machined, the other zone can be loaded and queued for machining.

SPINDLE CONFIGURATION

The machine is equipped with a 1 HP High Frequency 18,000 RPM Direct Drive Router Spindle mounted onto a 1/2" machined aluminum sur-

face. All wiring to the carriage is carried in an enclosed E Track to prevent damage to crical components. The 18,000 RPM spindle speed guar-

antees the boring bit concentricity, ensuring an accurate hole size for maximum glue contact. The high RPM also allows for rapid plunge boring

to be accomplished without losing the integrity of the boring surface. Pre-glued dowels can be used due to the accuracy and integrity of the

hole.

CLAMPS

The HP-49 comes standard with 4 quick adjust vercal clamps. Each clamp has 314 psi clamping force for maximum clamping capability.

GLUE INSERTER

The Glue Inserter is designed to accurately dispense glue into the hole in a predened metered amount. The glue nozzle is made of a self-

sealing nonsck Delrin material to allow for either glue or water to be used in the machine. It consists of an enclosed system using needle and

seat at valve, high pressure pump to 1,500 psi, with steel braided lines, innite adjustment to all valves.

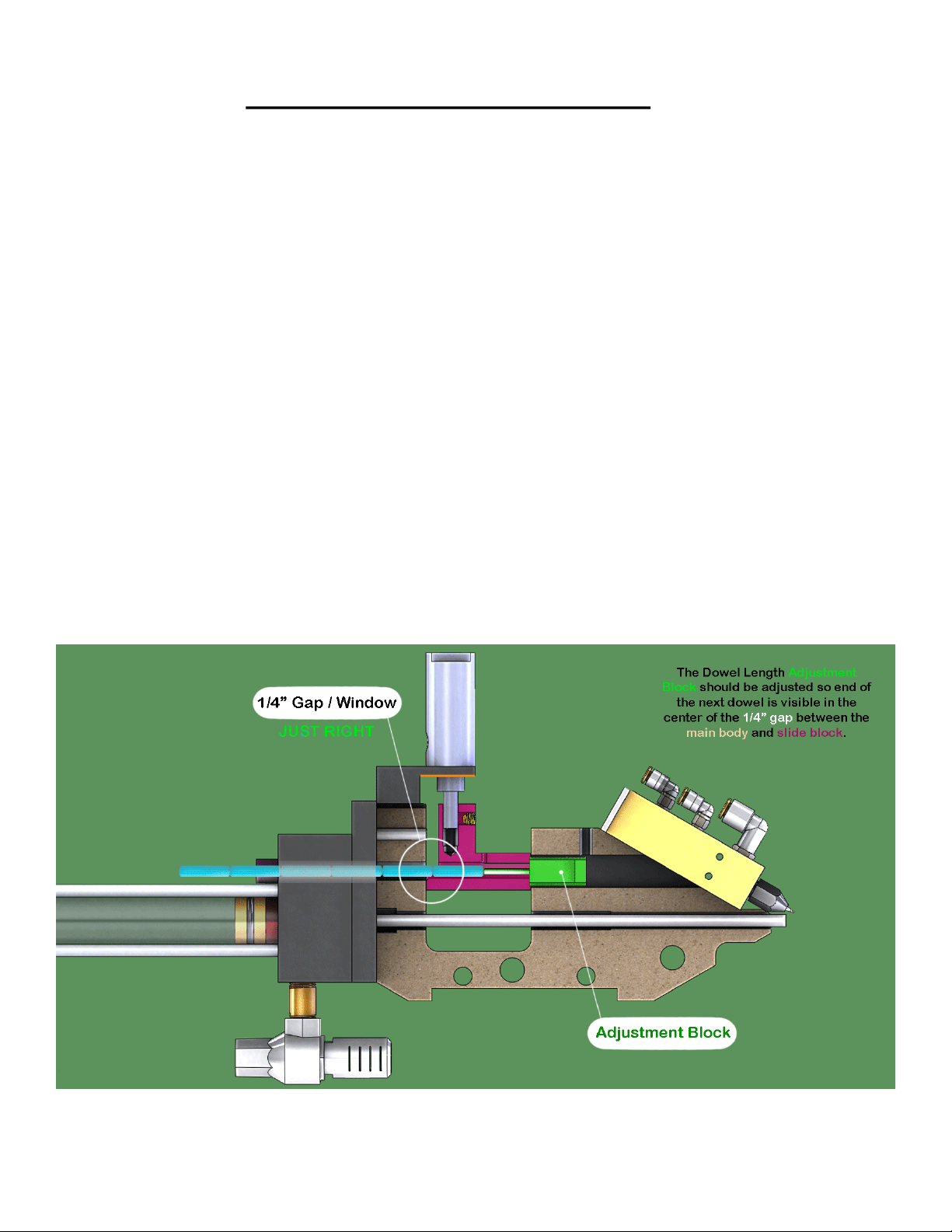

DOWEL INSERTER

Our patented dowel inseron system is a straight forward design. It has proven to reliably insert dowels without the need for realigned. Dowel

depth is set via a mechanical digital readout located on back of machine and is easily adjustable for dierent length dowels. The "Direct Reject

System" automacally detects an improperly sized dowel and noes the operator via the operator interface for dowel removal. The dowel

reject slide is opened, the dowel is removed, and then normal operaon is resumed.