- v -

Introduction

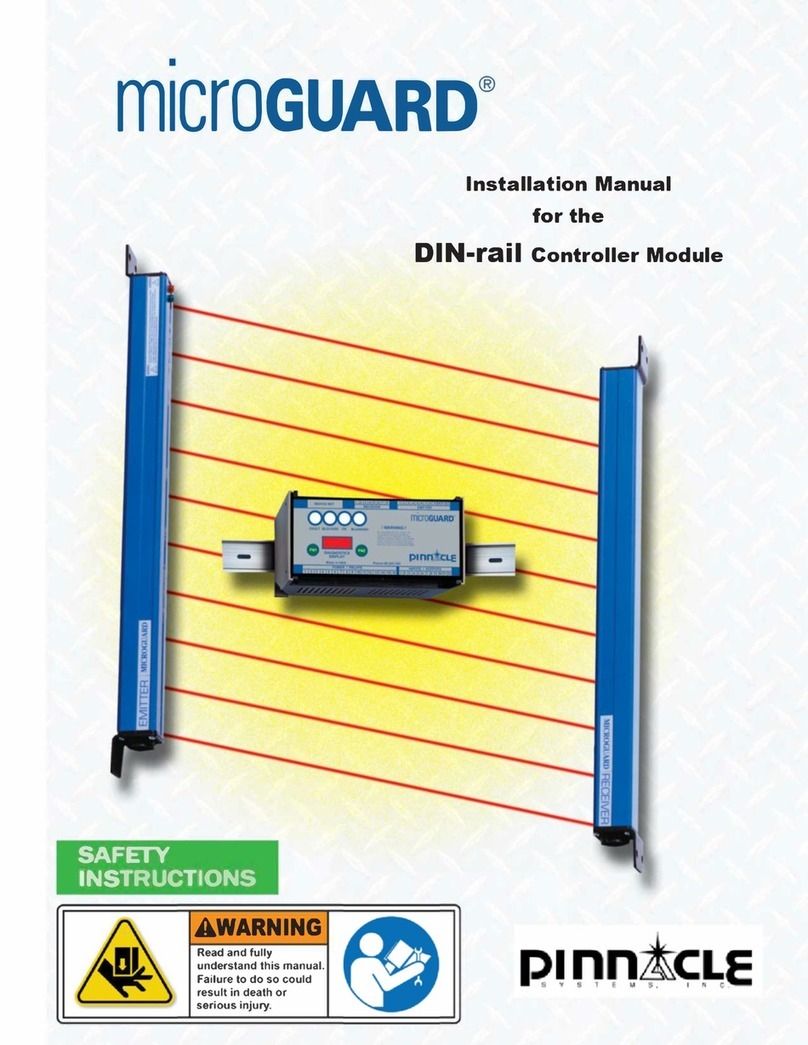

TheMicroGuardDIN-railController Module isaninfrared

safety light curtain that is designed to the European

IEC 61496 standard. IEC-61496 standard defines

requirements for infrared light curtains used in safety

applications. When properly installed, it protects the

machine operator by passing an invisible infrared light

beam across an area to be guarded and examining

whetheror notthe light beam(s)are blocked. Ifthe light

beams are blocked, safety outputs will automatically

open up and a “STOP” command will be sent to the

guarded machine.

The system is composed of a sending unit (Emitter), a

receivingunit (Receiver),and a Controller Module. The

entire system is control reliable (per IEC 61496) in that

a single fault anywhere within the MicroGuard DIN-rail

itself will not prevent the safety outputs from opening

up when anything blocks the infrared light beam(s). All

failures are reported on the Diagnostics Display and/or

via the RS-232 or RS-485 Serial Port.

The Diagnostics Display aids in installation by showing

where beam blockage is occurring, as well as reporting

selected installed options and fault reports.

Theoryof Operation. TheMicroGuard protectsanarea

byprojecting acurtain ofinfraredlight. It formsa curtain

by utilizing infrared Emitters in line on .5” or 1” centers.

This close spacing makes it impossible to place a body

part through the curtain without detection (assuming

properinstallationprocedures werefollowed). Forevery

infrared Emitter, there is an infrared Detector directly

opposite. When an obstruction is placed between

them,the beam isbroken and theabsence of a beam is

observed by the Controller Module which de-energizes

the safety relays and opens the connected circuit.

All the beams are scanned sequentially (one at a time)

until the entire curtain has been scanned. The two

computers compare data with each other every scan

of the light curtain and will drop out the safety relays if

any signal is incorrect or the compared data does not

match. Cooperationfrom both computers is requiredto

energize safety relays and either computer can disable

both safety relays if a fault is detected.

The System. The MicroGuard employs infrared

technologyina smallsealedNEMA4 aluminumhousing

which provides harmless invisible protection and an

unobstructedview of theguarded area. The Microguard

consists of three parts: an Emitter pylon(s), Receiver

pylon(s), and Controller Module. The Emitter pylon(s)

contains infrared light emitting diodes spaced .5” or 1”

apartdown the entirelength of thepylon. The Receiver

pylon(s)contains anequalnumber ofinfrared detector’s

and transistor receivers also spaced .5” or 1” apart.

The Controller Module contains diverse redundant

technologythat includestwo differentmicroprocessors,

self-checking circuitry, power supply, safety output

contacts, and a diagnostics display.

System Safety. The MicroGuard employs diverse

redundant technology that provides a backup for every

system that could cause an unsafe condition. Upon

power up, all systems are checked before activating

the output relays. Once the unit passes the initial

tests and activates the system, it is then tested by

both microprocessors and other circuits once per scan

of the light curtain. All signals are presented to both

microprocessors, but are isolated from one another

to prevent a failure of one microprocessor should the

other crash. Other circuits detect short circuits, open

circuits, proper voltage, proper oscillation, etc. The

use of special dual force-guided safety relays assure

that if one fails, the other can safely shut down the unit.

Additionally, watchdog circuits on the relays prevent an

unsafe condition even if both microprocessors failed.

All the standard and optional features that run on the

MicroGuard are designed with safety in mind:

The Floating Blank option allows only one object

to be placed into the light curtain’s field of view.

Evenif theobject is smallerthan theallowed size,

a second object will cause the unit to go RED.

The Auto Blank option programs in the exact size

and location of an object automatically and thus

can detect any movement in the object and shut

down the light curtain, which must be reset with

a key.

The External Relay Check can detect either an

opening or a short in the external relay or its

wiring. Thestandard Cincinnati Interfaceprovides

a means to assure that the light curtain can open

up its output relays between press cycles.

Safety Features. The MicroGuard was designed to

meet the European IEC 61496 standard parts 1 and 2,

CSA, UL1998, ULSubject 491, OSHA,ANSI, and RIA.

• Control-reliable design prevents a failure to

danger condition from ever occurring (assuming

all installation procedures are followed properly).

• Systemredundancyassuresthat there areatleast

two ways to detect a system failure, two ways

to shut down the safety outputs, and two safety

outputs. The redundant systems are configured

differentlytoprevent any possible inherent circuit

- iv -