Symbol Signal

word

Meaning

ATTEN-

TION

This symbol warns

against possible damage

to property or equipment.

IMPORT-

ANT

This symbol indicates

important facts and states

as well as referring to fur-

ther information in these

operating and assembly

instructions. It also refers

to certain additional in-

structions, which provide

additional information or

help you to carry out a

procedure more simply.

Protection class I symbol

Fig. 3 Notation for damage to property and additional

information

The following example illustrates the basic structure of a safety

note:

SIGNAL WORD

Type and source of danger

Explanation of type and source of danger

►Measures to avoid the danger

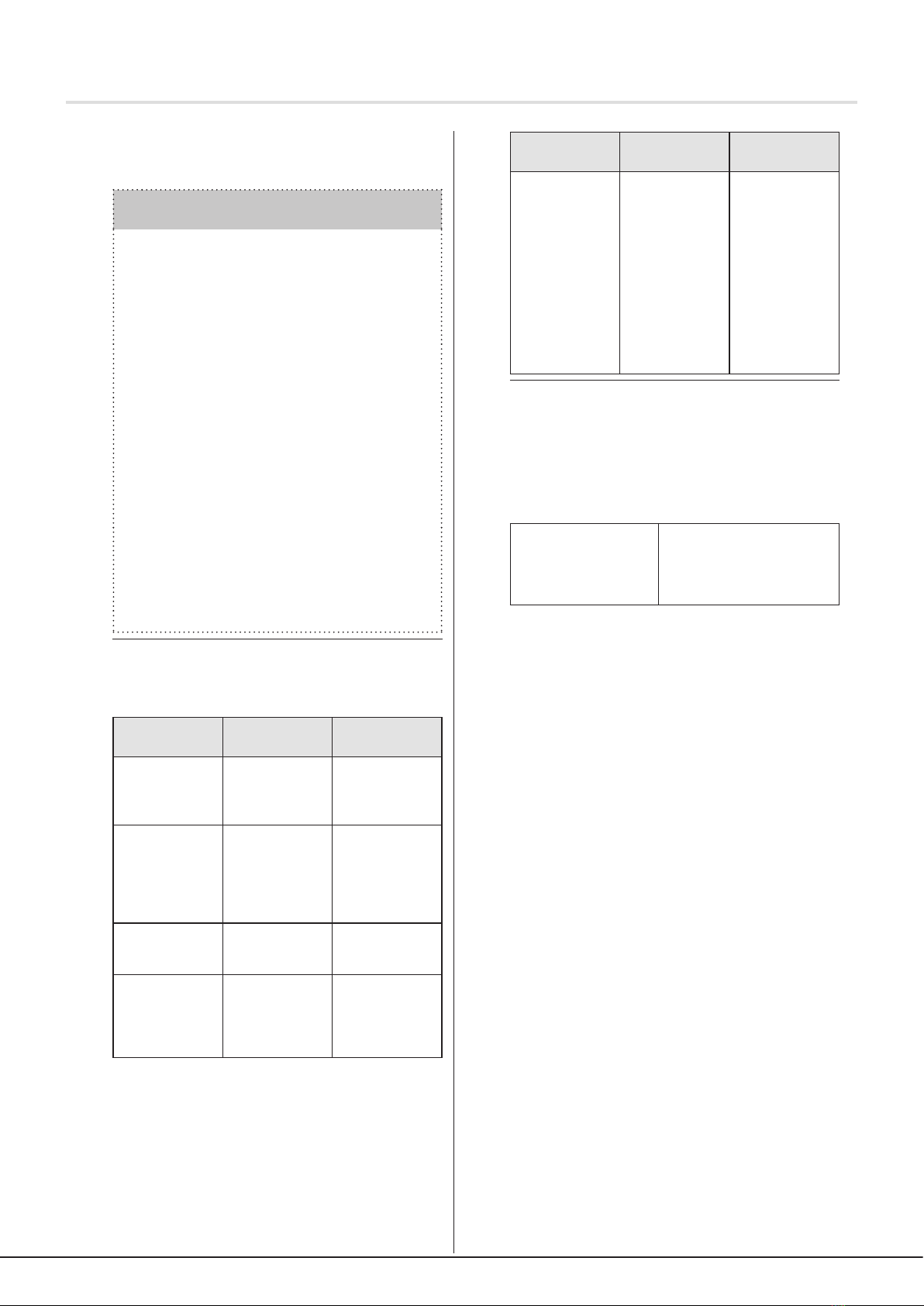

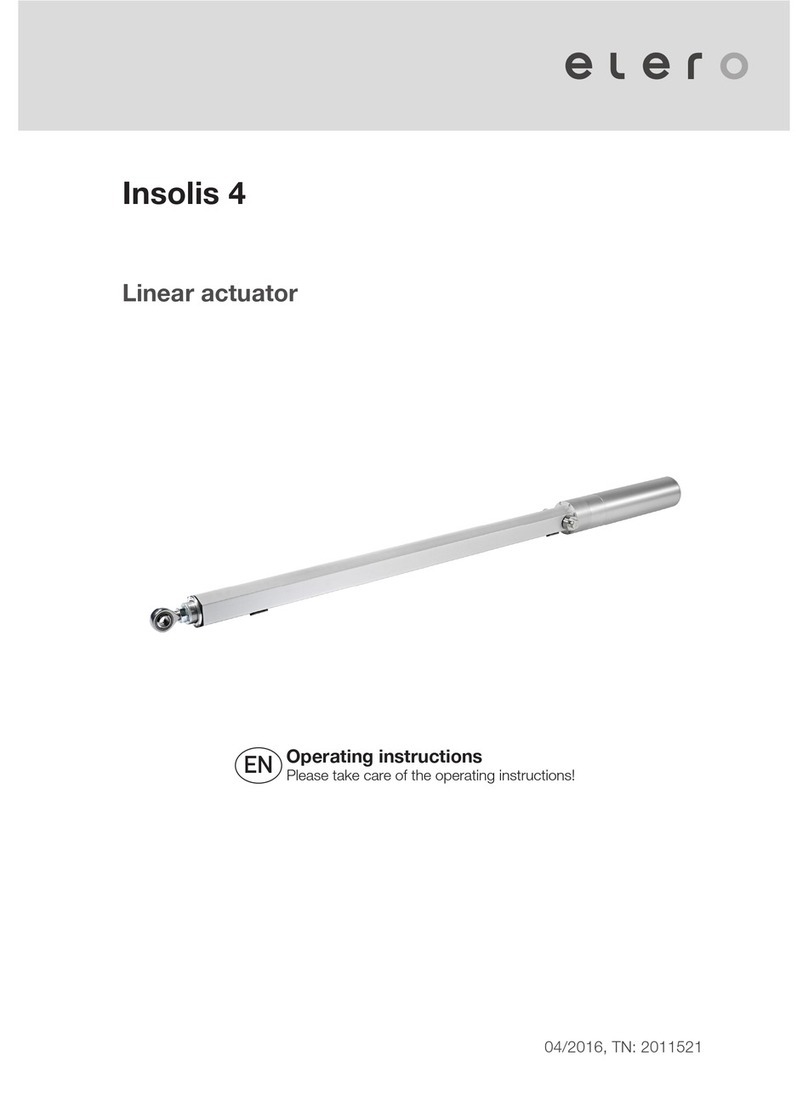

4 Product description

The InDrive M30/1.6 RH is an electromechanical tubular drive

for sun protection systems with horizontally moving slats.

During operation it executes radial movements.

Commissioning of the InDrive M30/1,6 RH with elero

assembly cable for the conguration of various functions.

Slat protection with free travel (torque limiting).

Release function for the slats

4.1 Product contents

Drive with safety instructions and operating instructions and

any additional components and accessories according to the

order conrmation or delivery note.

4.2 Accessories

Connection and assembly cable, adapter sets, motor bearing,

ProLine control units, sensors, receivers.

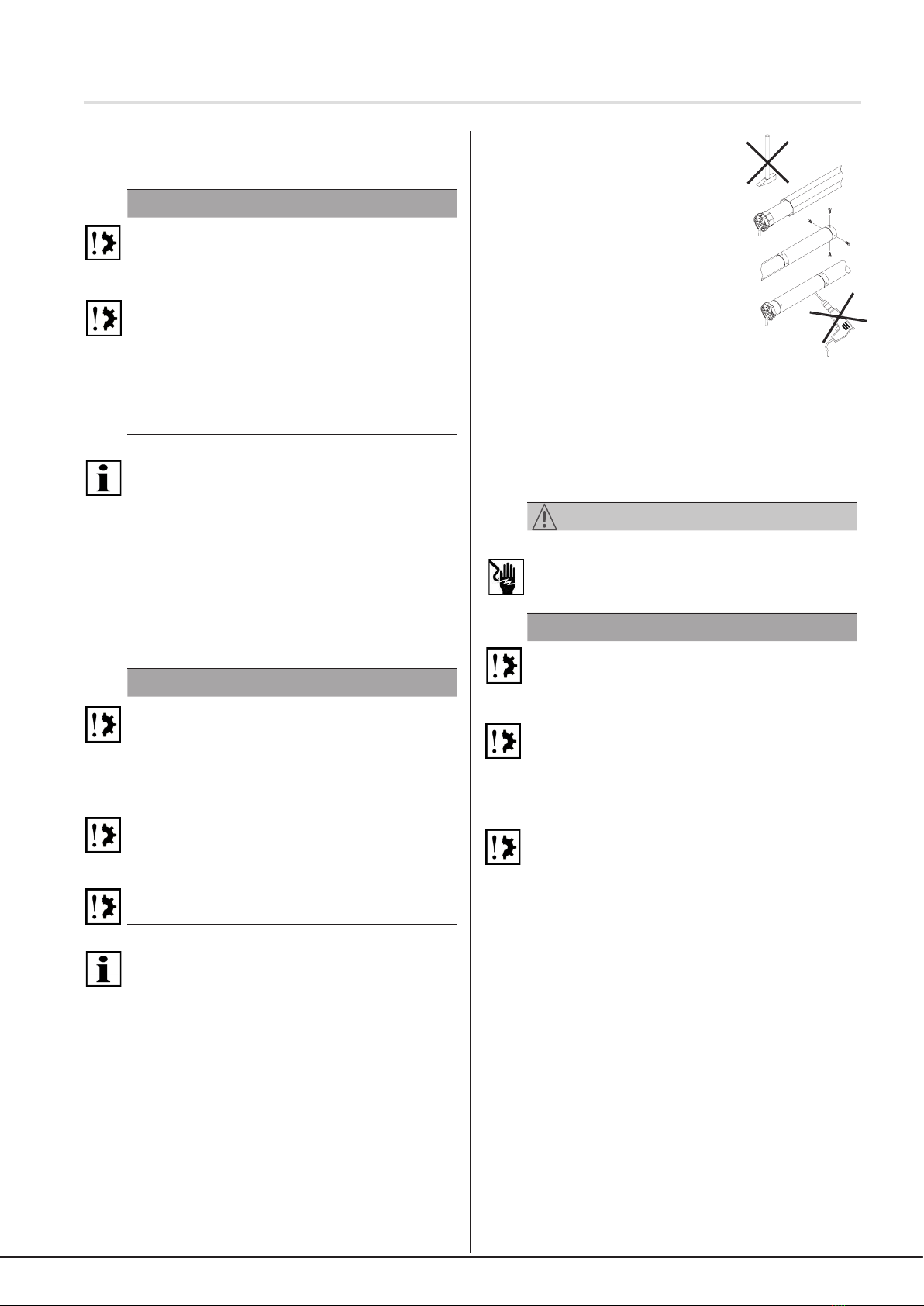

5 Assembly

WARNING

Important safety instructions.

Observe all assembly instructions since incorrect assembly

can lead to serious injuries.

►Commissioning of the InDrive M30/1.6 RH with elero

assembly cable for setting various functions.

►Before installation, all cables and components that are not

required and all facilities that are not needed for operation

with a power drive are to be disabled.

►The required components are: drive, connection and

assembly cable, motor bearing, adapter sets, if necessary

rigid shaft connectors, sensors, control devices, receivers.

►If components are not delivered with the drive, these can

be identied via our catalogue "Drives and control units for

intelligent building technology" in the relevant valid version.

Further details can be found on our website under "Contact

- Dealer Search" and "Contact - Partner Area".

►The rated torque and rated operating time must be suitable

for the properties of the driven part (the slats of the sun

roof).

►The coupling of the drive with the powered part is described

in the section "Mechanical fastening".

CAUTION

Risk of injuries due to hot surfaces.

The drive will heat up during operation, the drive casing can

become hot. Skin burns are possible.

►Wear personal protection equipment (protective gloves).

Triggered by a possible material fault, knocks or impact

injuries may arise due to a gear fracture, burring fracture or a

coupling defect.

►Suitable materials have been used for the engineering

design and random sample testing by means of a double

load test has been performed in accordance with DIN EN

60335-2-97.

Risk of injury due to knocks or impact triggered by motor

bearings that are incorrectly mounted or engaged. Hazard

due to insufficient stability or steadiness and accumulated

energy (gravity).

►Selection of motor bearing by torque specications.

►The drive must be protected with all the enclosed safety

devices.

►Check for correct engagement on motor bearing and the

correct screw tightening torques.

WARNING

Risk of injury due to electric current.

Risk of electric shock.

►Always have electrical work carried out by an authorised

electrician.

Risk of injury due to electric current.

Possible danger due to parts that are faulty becoming

energised.

►Electrical connection is described in the operating and

assembly instructions, including cable routing.

►The drive falls under protection class I (protective

conductor system). All housing parts of the drive capable

of conducting electricity are connected with the protective

conductor system of the xed electrical installation, which

is located at potential earth. The protective conductor

connection is designed so that, the rst time the plug is

inserted, it is connected rst and, in case of any damage,

it is disconnected last. The connecting cable is tted with

mechanical strain-relief when inserted in the drive. If the

cable is torn out, the protective conductor will be torn o last.

If, in case of a fault, a live cable comes into contact with the

housing, which is connected with the protective conductor,

a short circuit will generally arise so that the fuse itself is

triggered and de-energizes the electric circuit. No electricity

will be conducted to human beings in case of a fault. 4-core

connecting cables (4 x 0.75 mm2cross-section with black

CONINVERS plug) are used for the electrical connection with

an earthing contact that is conducted to the exterior.

CAUTION

Risk of injury due to malfunctions as a result of incorrect

assembly.

© elero GmbH EN | 3

Product description | Assembly (mechanical fastening)