3

XDJ-700

56 7 8

56 7 8

A

B

C

D

E

F

CONTENTS

SAFETY INFORMATION.......................................................................................................................................................... 2

1. SERVICE PRECAUTIONS.................................................................................................................................................... 3

1.1 NOTES ON SOLDERING ............................................................................................................................................... 3

1.2 NOTES ON REPLACING PARTS ................................................................................................................................... 4

1.3 SERVICE NOTICE.......................................................................................................................................................... 4

2. SPECIFICATIONS................................................................................................................................................................. 5

3. BASIC ITEMS FOR SERVICE .............................................................................................................................................. 6

3.1 CHECK POINTS AFTER SERVICING ........................................................................................................................... 6

3.2 JIGS LIST ....................................................................................................................................................................... 6

3.3 PCB LOCATIONS ........................................................................................................................................................... 7

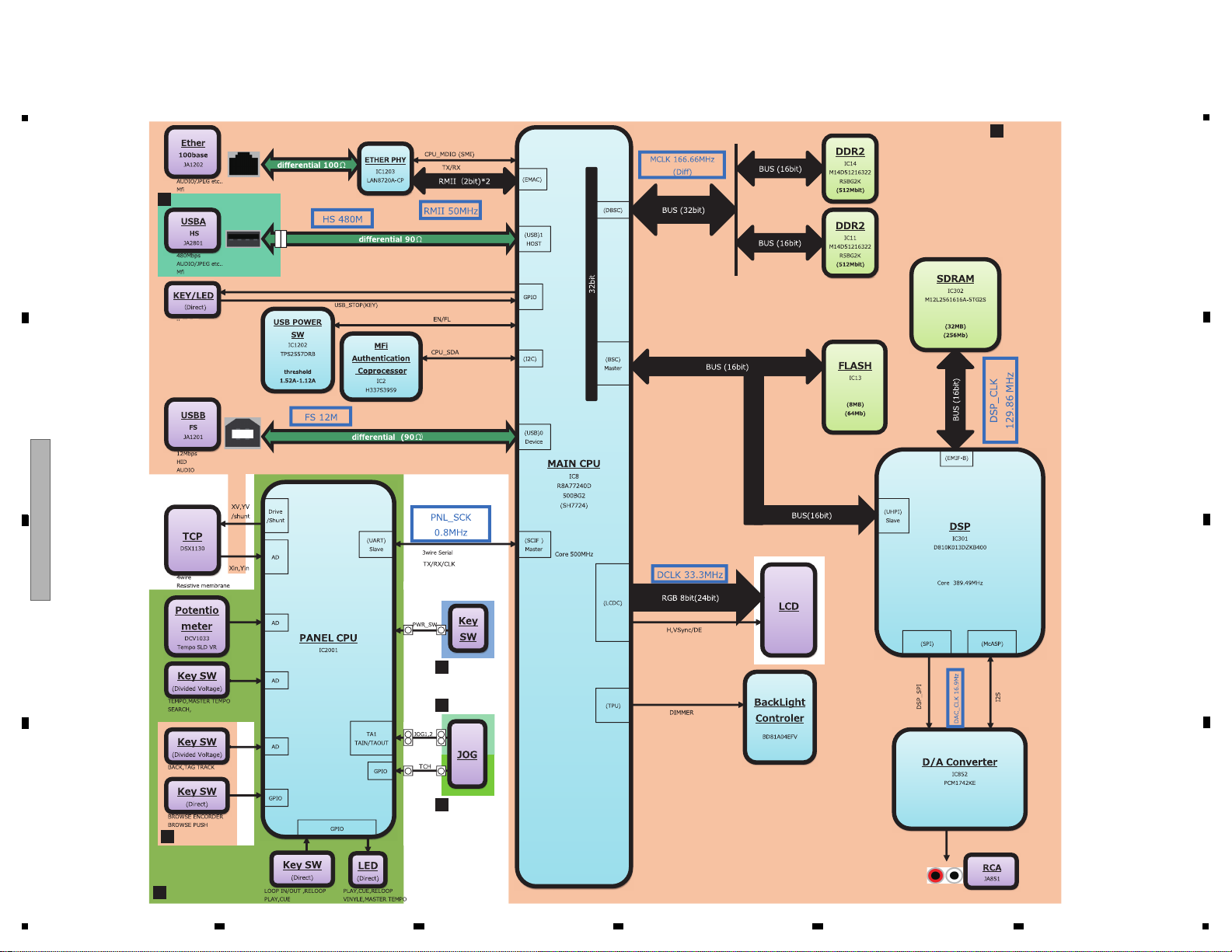

4. BLOCK DIAGRAM ................................................................................................................................................................ 8

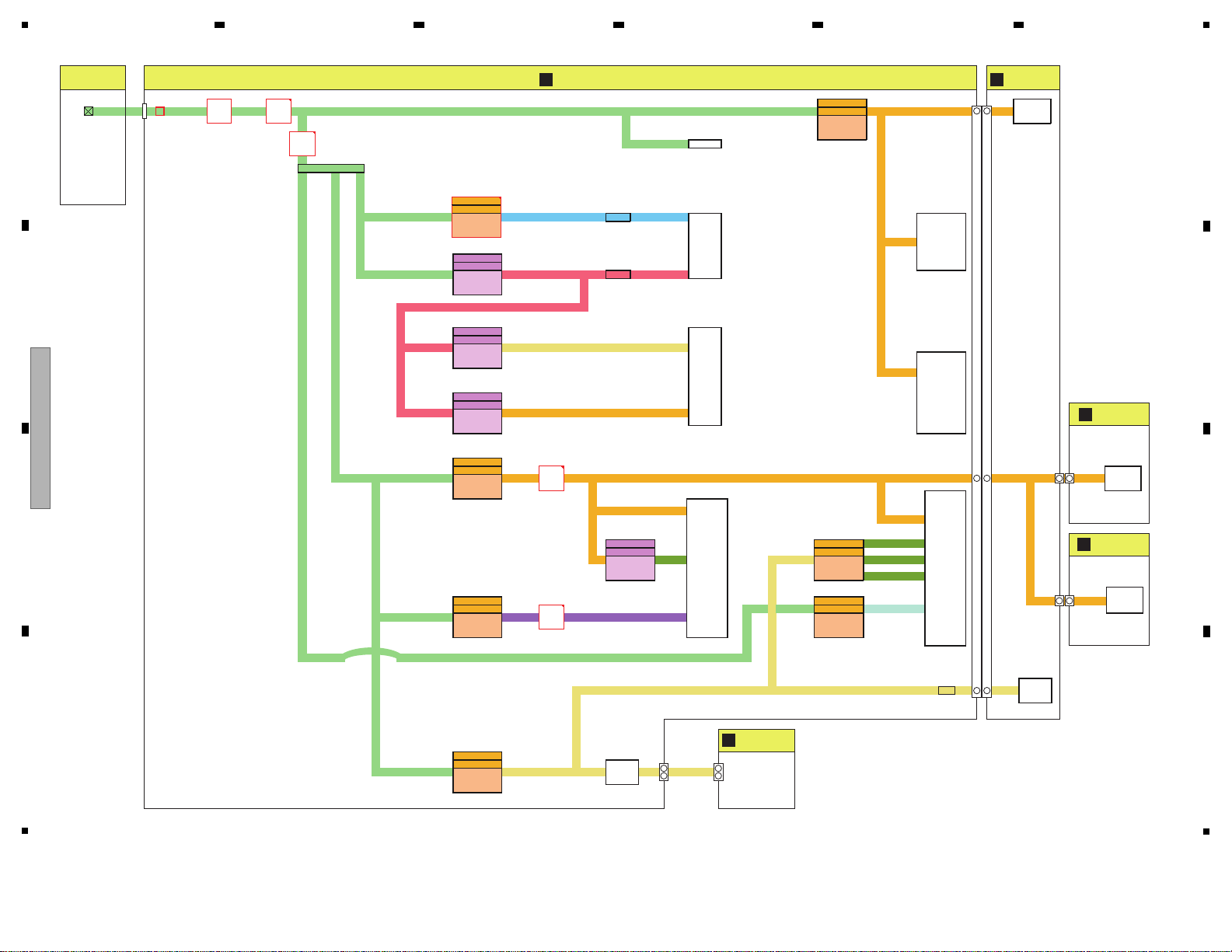

4.1 OVERALL WIRING DIAGRAM ....................................................................................................................................... 8

4.2 SIGNAL BLOCK DIAGRAM............................................................................................................................................ 9

4.3 POWER SUPPLY BLOCK DIAGRAM........................................................................................................................... 10

5. DIAGNOSIS ........................................................................................................................................................................ 11

5.1 POWER ON SEQUENCE............................................................................................................................................. 11

5.2 TROUBLESHOOTING.................................................................................................................................................. 12

5.3 CONNECTION CONFIRMATION WITH THE PC......................................................................................................... 20

6. SERVICE MODE................................................................................................................................................................. 21

6.1 SERVICE MODE .......................................................................................................................................................... 21

6.2 ABOUT THE DEVICE................................................................................................................................................... 29

7. DISASSEMBLY ................................................................................................................................................................... 30

8. EACH SETTING AND ADJUSTMENT ................................................................................................................................ 38

8.1 NECESSARY ITEMS TO BE NOTED........................................................................................................................... 38

8.2 FIRMWARE UPDATE / RECOVERY............................................................................................................................. 38

8.3 WRITING THE SERIAL NUMBER OF THE UNIT ........................................................................................................ 38

8.4 JOG DIAL ROTATION LOAD ADJUSTMENT ............................................................................................................... 39

8.5 ITEMS FOR WHITCH USERS SETTING IS AVAILABLE............................................................................................. 40

9. EXPLODED VIEWS AND PARTS LIST............................................................................................................................... 41

9.1 PACKING SECTION ..................................................................................................................................................... 41

9.2 EXTERIOR SECTION .................................................................................................................................................. 43

9.3 DISPLAY SECTION ...................................................................................................................................................... 45

9.4 JOG DIAL SECTION .................................................................................................................................................... 47

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

Do NOT use a soldering iron whose tip temperature cannot be controlled.