Pioneer CT-7R User manual

Other Pioneer Cassette Player manuals

Pioneer

Pioneer KEH-P4025 User manual

Pioneer

Pioneer FH-P6200 User manual

Pioneer

Pioneer CT-40 User manual

Pioneer

Pioneer CT-110 User manual

Pioneer

Pioneer CR-F750 User manual

Pioneer

Pioneer CT-W505R User manual

Pioneer

Pioneer CT-W606DR - Dual Cassette Deck User manual

Pioneer

Pioneer KEH-P7020R User manual

Pioneer

Pioneer KEH-P7035 User manual

Pioneer

Pioneer CT-550 User manual

Pioneer

Pioneer DC-X77Z User manual

Pioneer

Pioneer XR-A670 User manual

Pioneer

Pioneer CT-S99WR User manual

Pioneer

Pioneer CT-W208R - Dual Cassette Deck User manual

Pioneer

Pioneer CT-F7070 User manual

Pioneer

Pioneer CT-S830S User manual

Pioneer

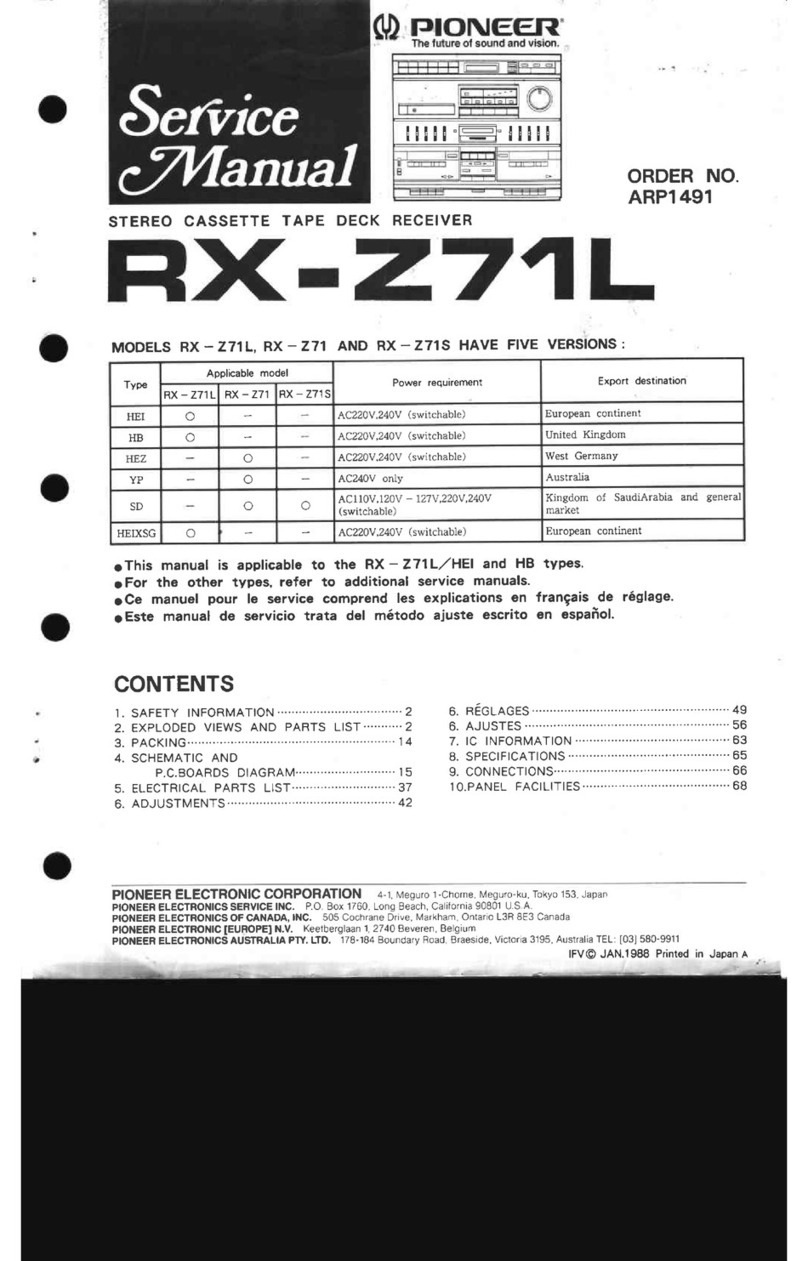

Pioneer RX-Z71: User manual

Pioneer

Pioneer CT-W510 User manual

Pioneer

Pioneer CT-S920S User manual

Pioneer

Pioneer KEH-1033 User manual