CX-31686

1234

1234

C

D

F

A

B

E

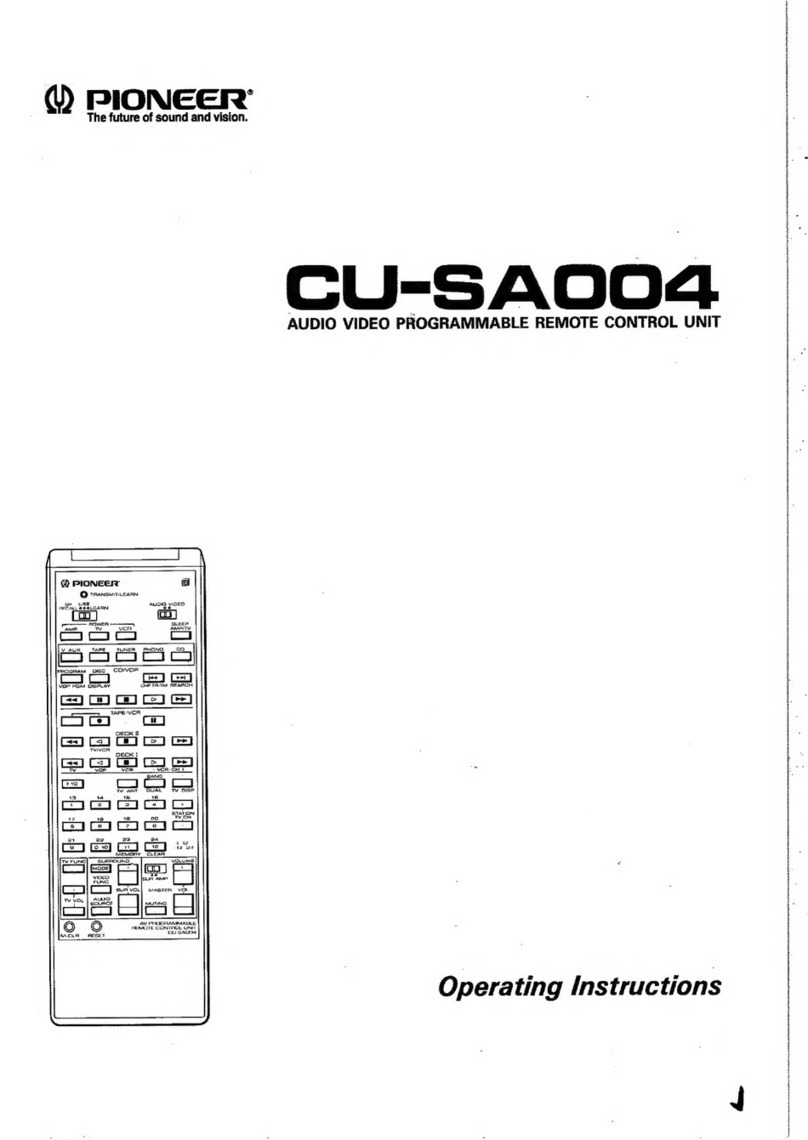

1.2 SERVO SECTION (UPD63763AGJ,UPD63761AGJ: IC 201)

1) Focus servo system

FE

AMP DIG.

EQ

125

A+C

B+D FD FO+

FO-

IC302

BD7962FM

LENS

IC201 UPD63763AGJ,UPD63761AGJ

128 101 18

17

FOCUS SEARCH

TRIANGULAR

WAVE GENERATOR

DAC

CONTROL

A/D R218

10K

R311

C219

1000pF

8R2K

R313

27K

C302

150P

10

11

Fig.5 Focus servo block diagram

The servo section operates servo control such as

equalizing of error signal, in-focus, track jump, carriage

move, etc. DSP is section for signal processing and

operates data decoding, error correction, interpolation

processing, etc. FE, TE signal generated in preamp stage

is A/D converted and outputs drive signal of focus,

tracking, and carriage system via servo block. And EFM

signal is decoded in the signal processing section and

outputs audio signal after D/A convert via D/A converter

finally. In addition, in this decoding process, error signal of

a spindle servo is generated, and supplied to the spindle

servo section, and outputs drive signal for the spindle.

Each drive signal of focus, tracking, carriage and spindle

is amplified by the driver IC BD7962FM (IC302) after that

and supplied to each actuator and motor.

The main equalizer of focus servo is made up of digital

equalizer section. The fig 10 shows a block diagram of

focus servo.

In the focus servo system, it is necessary to bring a lens

within in-focus range to focus-close. In order to do that,

triangle wave of focus search voltage moves a lens up

and down to find in-focus point. During that time, a

spindle motor is kicked to maintain rotation at the fixed

speed. The servo LSI monitors FE signal & RFOK signal,

and operates focus-close automatically in appropriate

point. The focus-close is performed when following 3

conditions are set;

1A lens is moving from away to near toward a disc.

2RFOK= "H"

3Just at the moment when FZC signal is once over the

threshold of FZD register and latched to "H" again (the

edge of FDZ). As the result, FE converges "0" (=REFO).