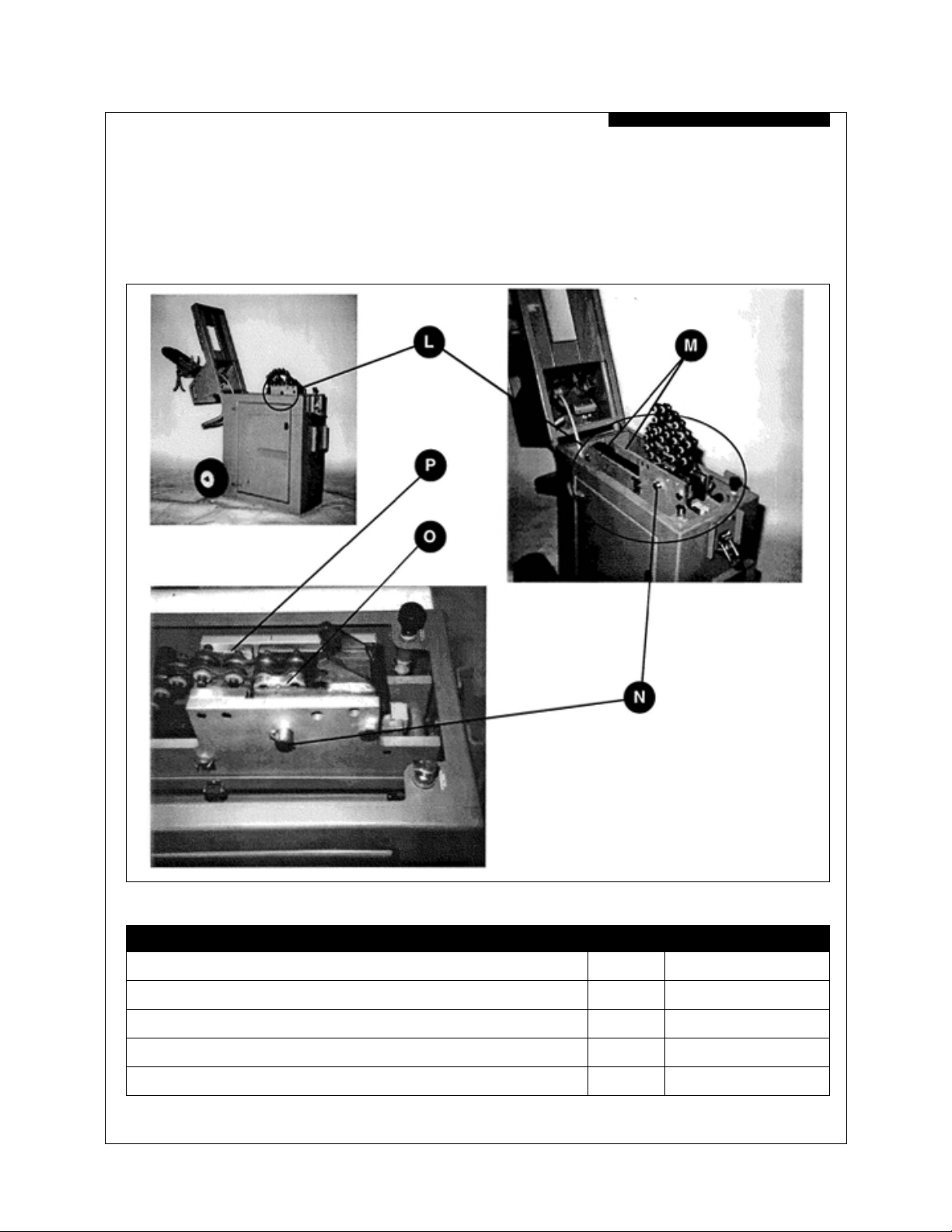

Flip motor control switch on front panel to the "OFF" position

before plugging the machine in. Make sure the cutting chain is

free from entanglements with other hardware, i.e. do not allow

the cutting chain to be hooked or bound in any way that would

prohibit free movement. When the machine is plugged into a

power source, the red indicator light on the front panel should be

illuminated. At this point, flip the motor control switch to the

"ON" position. If the hydraulic cylinder is at the proper reset

position, nothing should happen, i.e. the hydraulic pump motor

should not run and the cutting chain should not move. If the

hydraulic cylinder has retracted slightly from its reset position (as

might occur during transit or after a long period of storage), the

hydraulic pump motor will run long enough to allow the machine

to reset. Once reset, the hydraulic pump motor will shut off.

(When the unit is plugged in, it is important to allow the cylinder

to go to its reset position, otherwise the valve that operates the

reset function will overheat.) In the event that the hydraulic

pump motor is running and the cutting chain is being pulled into

the mechanism (as would be the case when the cutting chain is

being tightened around the circumference of a pipe), verify that

the overarm (actuating arm) is in its relaxed and retracted

position (not in the actuating position).