Piper PA-28 Cherokee 140 User manual

PiperPA28Cherokee140

Specifications

¼scaleARF

wingspan100”

length73”(plusspinner)

wingarea1823sqinch

flyingweight1719lbs

cowl 103/4"x117/8'x95/8"

recommendedengines40cc50ccgas

features–carbonwingtubes,paintedfiberglasscowl,machinedaluminumOleostrut

TableofContents

PartsNeededToCompleteKit ….. page1

EngineBox ….. page2

Ailerons&Flaps ….. page5

VerticalStab&Rudder ….. page8

HorizontalStab ….. page9

HorizontalStabControls ….. page11

RudderControls ….. page13

Canopy ….. page15

MainGear&Wheels ….. page16

NoseGearStrut ….. page19

FuelTank ….. page20

Engine,Muffler,Ignition ….. page21

Cowl ….. page23

RadioSetUp ….. page25

ControlThrows ….. page25

PartsNeededToCompleteKit

ÿ 1RudderServo(minimum100oz.torque)andmountinghardware(suchasHitecHS645MG)

ÿ 1LargeRudderServoArm

ÿ 1ElevatorServo(minimum100oz.torque)andmountinghardware(suchasHitecHS645MG)

ÿ 2AileronServos(minimum70oz.torque)andmountinghardware(suchasHitecHS645MG)

ÿ 2FlapServos(minimum50oz.torque)andmountinghardware

ÿ 1NoseWheelServo(minimum50oztorque)andmountinghardware

ÿ 1ThrottleServo(minimum40oz.torque)andmountinghardware

ÿ 124inchServoExtension(Elevator)

ÿ 224inchServoExtensions(Ailerons)

ÿ 26inchServoExtensions(ThrottleandNoseWheel)

ÿ 3“Y”ServoExtensions(Flaps,Ailerons,Rudder/NoseWheel)

ÿ 1–3inches1/8inchHeatShrinkTubing

ÿ 1–3inches5/8inchHeatShrinkTubing

ÿ 1Engine40ccto50ccgas(recommendedDLE55)

ÿ 1–IgnitionBattery(asperyourenginemanufacturer’sinstructions)

ÿ 1–Propeller2022inch(weused22x10)

ÿ 1RadioTransmitter(minimum5channels)

ÿ 1Receiver

ÿ 1ReceiverBattery

ÿ 1SwitchHarness

ÿ 13½inchAluminumSpinner

Notes:Loctiteeverythingthatdoesn’tneedtoberemovedoradjustedoften.

TestFitallTNuts(BlindNuts)toallowboltstobeeasilystartedbyhandandavoidcrossthreads.AstripedTNutcanbe

difficulttoreplace.

Page1

EngineBox

Collecttheseparts:

ÿ 6plywoodsidesofEngineBox

ÿ 2sizesofWoodenTriangularStock

The6piecesoftheEngineBoxareallnotcheddifferentlytoassurecorrectassembly.Trialfitallthepieces.

Sandifnecessary.Whensatisfied,glueallpiecesusing30minuteEpoxyGlue.Holdpiecestogetherforatight

fitusingclamps.

Note:30minuteEpoxyGlueisoftenbetterthan5minuteEpoxyGluebecauseithasmoreworkingtimeandisnotasbrittle.

Removeclampswhenglueissetandsandaslightbevelonsidesandcornerstohelpwithclearancewhenslidingintoplace.

Page2

Slideboxinplace/intofrontoffuseagainmakingsureyouhavaagoodfit.

Whensatisfied,glueboxintoplacewith30minuteEpoxyGlue.Againclampwhereableuntilgluedries.

BraceallfoursidesinsidetheengineboxfrontwiththesmallersuppliedTriStock.GluethelargerTriStocktotheoutside

sidesofengineblock.

Page3

Tohelpprotectallwoodsurfacesontheoutsideofthefirewallandengineblockwerecommendgivingtheseareasacoatof

30minuteEpoxy.

Hint:MixenoughEpoxyGluetodothejobanduseasmallstiffbrush.UseyourHeatGuntowarmtheglueasyou

brushiton.Theheatwillhelpthinthegluegivingamuchsmootherglasslikefinishwhendry.ItalsohelpstheEpoxy

Gluesoakintothewoodeasierforgreaterprotection.

Note:TheEpoxywillsetupfasterwhenheated.

Page4

Ailerons&Flaps

Collecttheseparts:

ÿ 2–MainWings

ÿ 2Ailerons

ÿ 2Flaps

ÿ 4–ServoHatchCovers

ÿ 16–HatchCoversScrews

ÿ 4ThreadedPushRods

ÿ 2TrumpetBases

ÿ 2TrumpetWashers

ÿ 2TrumpetScrews

ÿ 2ControlHorns

ÿ 2Clevises

ÿ 2AileronServos(minimum70oz.torque)

andmountinghardware(suchasHitecHS645MG)

ÿ 2FlapServos(minimum50oz.torque)andmountinghardware

ÿ 218inchAileronServoExtensions

TheAileronsandFlapshavebeenpredrilledandtheHingePinsinstalledbutnotglued.Assuretheyfitandare

rotatedsotheHingePinbendsproperlybeforeusingEpoxyglue.

Tip:TohelpkeepglueoutoftheHingePinjoint,applyasmalldropoflightoil.

FindtheopeningsinthebottomofbothWingsforthe

AileronandFlapServosandcutoutthecoveringcornerto

cornerwithanXActoKnife.UseaHeatSealingIronto

stickthecoveringtotheedges,cuttingofftheexcess

covering.

Use anXActoKnifetocutthecoveringforthePushRodsslotsin

the2AileronHatchCovers.TheFlapHatchCovershavenoslots.

PositiontheAileronHatchCoverssotheServoarmisonthewing

tipsideandControlSurfaceside.

Page5

Withthehatchcoverinplacepokeaholeinthecoveringfor

eachscrewholeanddrill1/16”holesintheWingforthe

HatchCoverScrews.

AddagussetofEpoxyGluearoundthebaseofeachServoMounting

Postforextrastrength.

Tip:AlsoinstallingasmallwoodscrewthroughthetopoftheServo

HatchCoverintotheServoMountingPostwillprovidesuperior

strength(optional).

PositiontheAileronServossotheServoArmexitsthemiddle

oftheHatchcutout.PredrilltheholesintheMountingPosts

witha1/16inchDrillBit.AttachServostotheHatchCover

MountingPostsusingthehardwaresuppliedwithyourServos.

DothesamefortheFlapServos.

Attachan18inchServoExtensiontoeachAileronServo.Usingalightstring,tieanutorsmallweightooneend

anddropitthroughtheWingRibopeninguntilitappearsintheAileronHatchopening.Tapeortiethestringto

theServoLeadandcarefullypullitthroughthewing.YoumaybeabletogettheFlapServo leadthroughthe

Wingwithouttyingaweight.

TIP:Heatshrinka11/4inchpieceof5/8inchwideshrinktubingovereachServoExtensionconnectionto

preventthemcomingapart

.

Page6

ToinstallthesuppliedControlHornspositiontheTrumpet

BaseatthebevelededgeoftheAileronandalignwiththe

AileronPushRodandmarkthelocation.Drilla3/32inch

diameterholeonthesemarks.

TIP:Strengthentheholesbyapplyingafewdropsofthin

CAGlueinbothholestoreducetheamountofBalsa

compression.

InstalltheTrumpetBasewiththeTrumpetScrewand

WasherontheothersideoftheElevator.Donotover

tighten.

InstalltheControlHornandClevisontheTrumpet

Base.ThreadtheAileronPushRodintotheClevisand

makea“Z”bend”intheotherendtoinstallthrough

yourAileronServoArm.

Tip:Doublecheckthelengthbeforemakingthe“Z”

bendwiththecontrolsurfaceattheneutralposition.

AttachaClevistoeachFlapPushRodsandconnecttoeach

FlapServoArmwith a“Z”bend.PositiontheHatchCovers

sothePushRodsgoesthroughtheholeinthetrailingedge

oftheWingandconnectswiththeFlapControlHorn

(alreadyinstalled).SecurebothFlapServo/Hatch

Assembliestothewingusing4SmallWoodScrewsusing

thesameprocedureastheAileronServoHatchCovers.

LocateandcutholesintheCoveringonbothsidesof

theFuselagefortheWingTube(1inch),WingBolt(1/4

inch),ServoLeads(9/16inch)andDowel(1/4inch).

Note:Ifthewingtubeisexcessivelytightwhenyoutest

fittheMainWingsusesome600GritSandpaper.

Page7

VerticalStab&Rudder

Collecttheseparts:

ÿ Fuselage

ÿ RudderTailBlock

Locatetheplastictubesalreadyinstalledinthetailblockfortherudderpullpullcables(coveredoverwithcovering).

Tofindthetubescoveredover...

Fromrearoftheblockmeasures53/4”

Fromthefin(atthemark)measure¾”

Theendofthetubeshouldbeattheintersectingmarks/measurements.

ChecktheTailblockwithfinforfit. AttachusingEpoxyGlue.Usemaskingtapetoholdinplaceuntilgluesets.

Note:Ifyouuse5minuteEpoxyGlueheresetinplaceandalignquickly.

UsingsamemethodaswithAilerons,useEpoxytogluetheRudderHingesinplace.

Tip:remembertouseadropoflightoilonthehingepinbeforeglueing.

Page8

HorizontalStabilizer

Collecttheseparts:

ÿ Fuselage

ÿ 2NylonBushings

ÿ CarbonFiberStabilizerTube

ÿ 2halvesStabilizer

ÿ ControlHornBolt

ÿ 256ElevatorPushRod

ÿ ElevatorPushRodClevis

YouwillfindtheCarbonFiberStabilizerTubepackagedinsidethe

CarbonFiberMainWingTube.

DrillthroughtheStabilizerTubefortheControlHornBoltsothatit

linesupwithyourElevatorServoPushRod.Werecommendyoufirst

EpoxyapieceofWoodenDowelinsidetheStabilizerTubefor

reinforcement,liningupwiththeholeyouwillbedrilling.Itwillstop

theControlHornfromcrushingtheCarbonFiberTube.Thedowelmay

alreadybegluedinplace.

Locatethe2NylonBushingsandinstalloneoneach

sideoftheFuselageintheprecutholesattherearof

thefuselage.SlidetheCarbonFiberthroughthe

bushings.Measuretherodoneachsidesoyouhave

itinthemiddle.

Note:YoumayhavetosandtheholesintheFuselageso

theNylonBushingssitlooseranddon’tbindtheStabilizer

Tube.

Page9

SlideeachhalfoftheStabilizerintoplace.

MakesuretheStabilizerrotatessmoothly.SandtheportionsofthetubethatinsertintoeachStabilizerhalfto

allowtheEpoxyGluetobondwell.

Important:BeforeglueingtheStabinstalltheControlHornBoltwiththeBoltpointingDOWN.

TrialfittheStabandoncesatisfiedgluebothendsoftheCarbonFibertubeandwheretheStabhalvesmeet

togetherwith30minuteEpoxyGlue.MakesuretheControlHornBoltremainsinpositionwiththeStabinthe

neutral(horizontalposition.ItisnotnecessarytoglueintheNylonBushings.

Whendryuseastripofwhitevinyltapetocoverthejointbetweenthetwohalves.

Findtheopeninginthebottomrearofthe

FuselageforaccesstotheHorizontalStabilizer

Servo.WithasharpXActoKnifecutoutthe

coveringanduseaHeatSealingIrontostickthe

coveringtotheedges,cuttingofftheexcess

covering.UseasmallscrewtosecuretheHatch

Cover.

Page10

HorizontalStabControls

InstalltheElevatorServointhecutoutlocationinthebottomofthe

FuselageattherearthroughthebottomHatch.WiththeServointhe

neutralposition,havetheServo Armextendtotheleftsideofthe

airplanetolineupwiththeStabControlHorn.

ThreadaClevisontoashortpieceof256rod,

threadedatoneend.Carefullymeasurethedistance

betweentheouterServoArmholeandtheholeinthe

StabControlHornandmakea“Z”bendatthismark

andtrimofftheexcessrod.

TestfitthenewPushRodtomakesureitmovestheStab

properly.Makesureitlinesupwithoneoftheslotsinthe

plywoodsurface(thatholdstheServo)toallowfull

movementoftheControlHorn.

Page11

Gluethe3WoodBlocksasshownwithEpoxyGlue.

Cut3piecesofstiffCardStock1inchx4inchesandtape

themontheFuselagesothattheendsoverlapthecenterof

eachWoodenBlock.Markthese locationsontheCardStock.

GentlyslidetheEndConeintoplaceunderthetabsandtapein

place.

Drillpilotholesthroughthecentermarkswith1/16inch

drillbit.Removethe CardStock anduseWoodScrewsto

attachtheEndConethroughtheholesyoudrilled.

Page12

RudderControls

InstallRudderServointhecutoutontheServotray.

Werecommendaminimum3inchwideServoArm.

TheRudderhas2TrumpetBasesthatscrewtogetherthrough

theRudder.

PositiontheTrumpetBaseattheedgeoftheRudderbeveled

edgeand1inchfromthebottomoftheRudderandmarkwhere

todrilla5/32inchholethroughtheRudder.Installthe2

TrumpetBaseswiththeTrumpetScrew.Donotovertighten.

TIP: StrengthentheholesbyapplyingafewdropsofthinCA

glueinbothholestoreducetheamountofBalsacompression.

Page13

CutthePullPullCableinto2equallengthsandthreadtheCablethroughthehoesintherearoftheFuselage.

ThreadoneCrimpFittingovertheendofoneCable,thenthreadtheCablethroughtheouterholeintheyour

LargeRudderServoArm.FoldbacktheCable1inchandslidetheCrimpFittingovertheCableend.When

satisfiedwiththefit,crimpthefitting.RepeatfortheotherendoftheServoArmwiththeotherCable.

TIP:Usea3/4inchpieceof1/8inchshrinktubingtocoverthe

sharpendoftheCablestickingoutofthecrimpedJointatbothends

oftheCable.YouwillhavetoslidethisonCableinadvance.

InstallaclevisontotheTrumpetbaseoneachsideofthe

Rudderthesameway.

Page14

Canopy

Collecttheseparts:

ÿ Canopy

ÿ Fuselage

ÿ 440SocketHeadBolts(2)

Testfittoseethateverythingisalignedandseatedproperly.Youmayhavetosandthefronttabsslightly.

Thecanopyholddowntabstotherearofthecanopyhavebeenpredrilledwithblindnutsinstalled.

Withthecanopyinplace,pokeaholeinthecoveringatthelocationofeachblindnut.Usesupplied440socketheadbolts

tosecurecanopyinplace.

Page15

MainGear&Wheels

Collecttheseparts:

ÿ 2PrebentLandingGearWireStruts

ÿ 2–FiberglassLandingGearFairings

ÿ 4–PlywoodFairing Inserts

ÿ 4–MetalMountingStraps

ÿ 8–SmallWoodScrews

ÿ 2–MainWingHalves

ÿ 2–MainWheels

ÿ 4–WheelCollars

YoucanupgradetheappearanceofthewirelandinggearwithRobarts#674ForkedRoboStruts.

UseanXactoKnifetocutoutthecoveringovertheslotin

eachWingfortheLandingGearStruts.

TrialfiteachLandingGeartoassureatightfit.

SetintheLandingGearStrutsandposition2oftheMetal

Strapsandmarkthelocationforthescrewholes.

Drillpilotholeswitha1/16inchdrillbit.

Page16

UsethesuppliedWoodScrewstoscrewthestrapsinplace

onbothWinghalves.

SlidethelargerFairingInsertoverthewireLanding

Gearwiththenarrowendtowardsthetrailingedgeof

theWingandtracearoundit.

UsingasharpXActoKnifecutoutthecovering

approximately1/16inchinsidethetracedline.

GluethelargerFairinginsertintoplacewithCAGlue.

UseaDremilTooltoelongatetheholeinthesmallerFairing

InsertsotheFairingswon’tgetrippedoffonarough

landing.

Page17

SlidetheFairingintoplaceandgluetothebottomlarger

InsertandthetopsmallerInsert.

DrillouttheWheelAxleHolewith¼inchdrillbittofit

fittheLandingGearWire.

SlideaWheelCollarontoeachLandingGearStrut.Slidethe

WheelonandthenanotherCollar.WiththeWheelcentered

inthemiddleoftheStruttightentheWheelCollarsjusttight

enoughsotheWheelturnsfreely.

Page18

Table of contents

Other Piper Toy manuals

Popular Toy manuals by other brands

Mega Construx

Mega Construx POKEMON WONDER BUILDERS PANCHAM GFV74 manual

Mattel

Mattel Barbie K8929-0520 instructions

Eduard

Eduard MiG-21PF manual

VQ Models

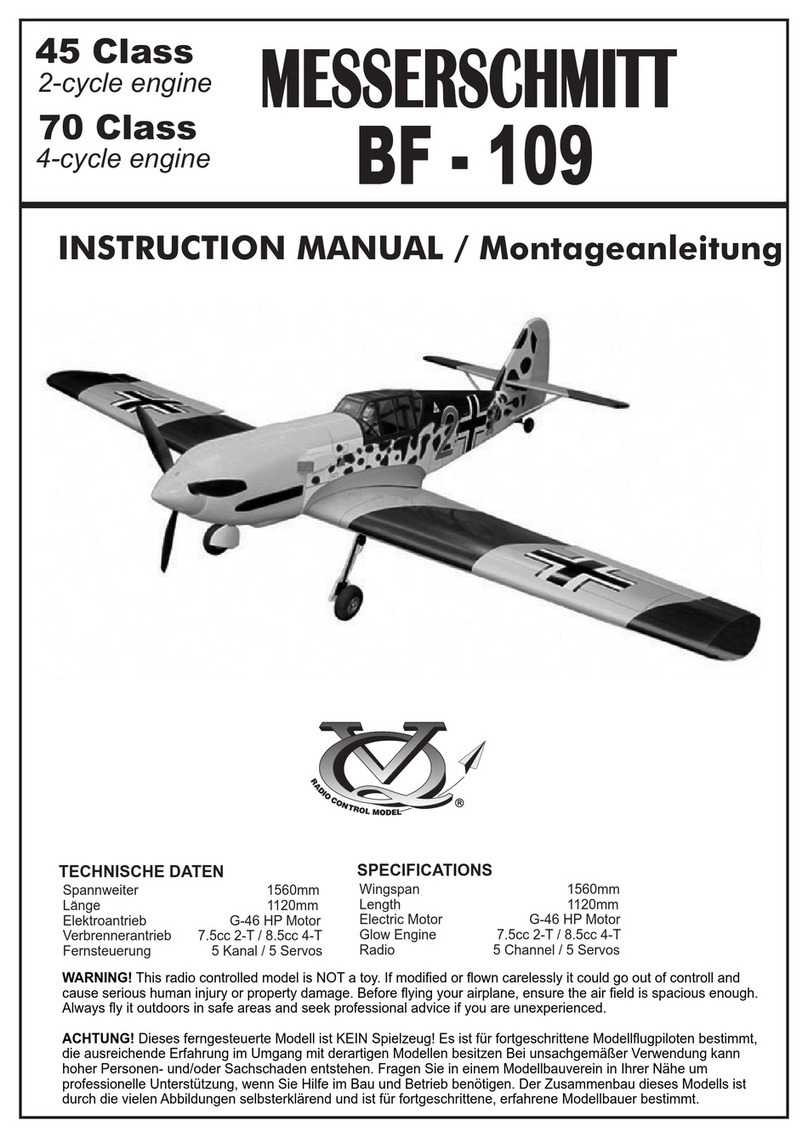

VQ Models MESSERSCHMITT BF-109 instruction manual

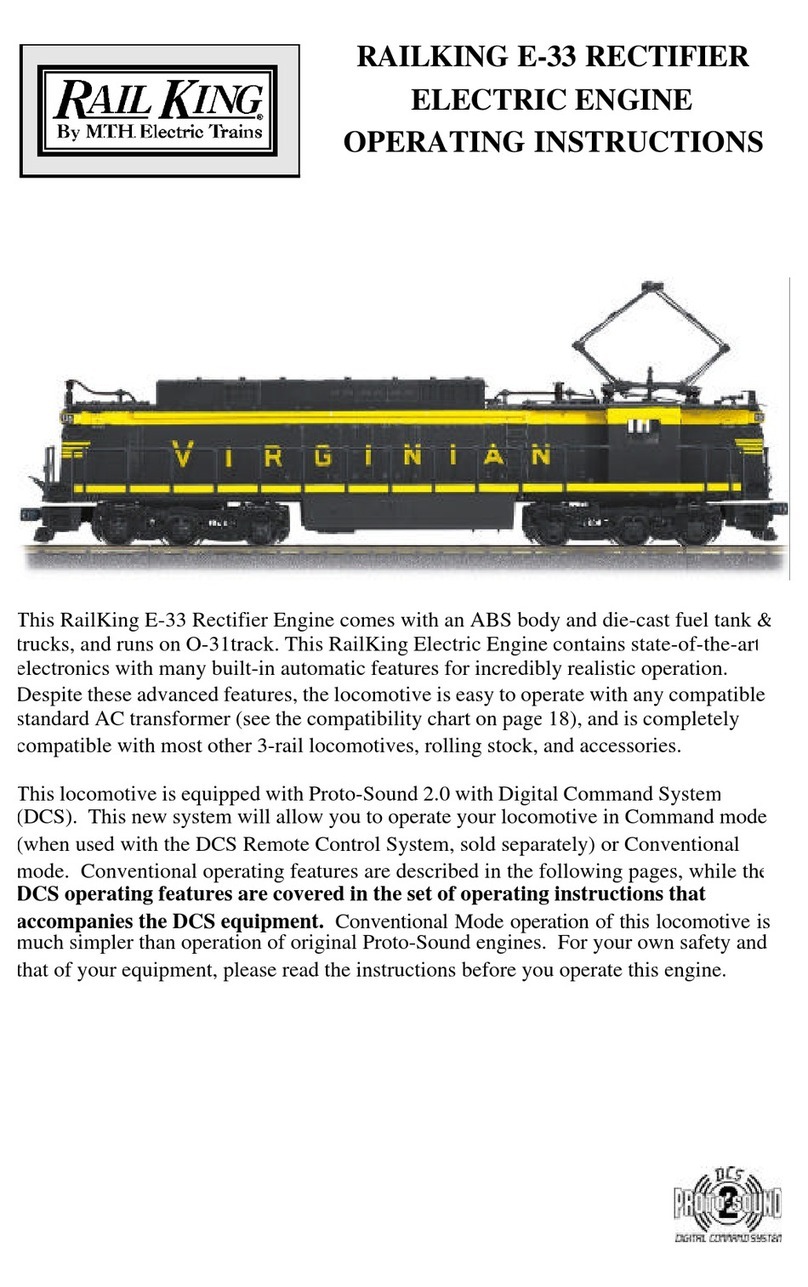

MTHTrains

MTHTrains E-33 operating instructions

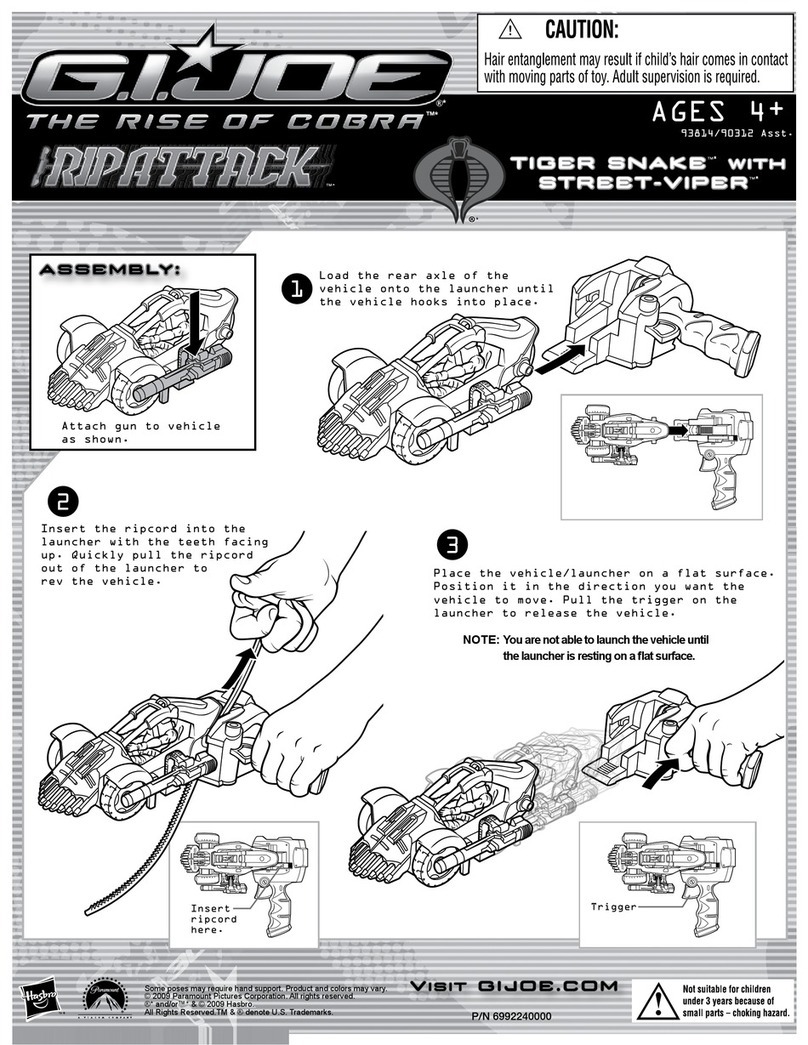

Hasbro

Hasbro G.I. Joe Ripattack Tiger Snake with... instructions