User manual - PDR100 - 3

Table of contents

1 Safety guidelines.....................................................................................................................................................4

1.1 Environmental policy / WEEE........................................................................................................4

2 Installation guidelines...........................................................................................................................................4

2.1 Organization of safety notices......................................................................................................4

2.2 Safety information.............................................................................................................................5

3 Preparing the installation....................................................................................................................................6

3.1 Product identification......................................................................................................................6

3.2 Installation considerations.............................................................................................................6

3.3 Selecting and preparing a site for installation.......................................................................6

3.4 Cable selection and cable wiring ................................................................................................7

3.4.a Signal (control) cable specifications............................................................................8

3.4.b Cable wiring ..........................................................................................................................8

3.5 Terminal screw specification.........................................................................................................9

3.5.a Input / Output terminal screw specification............................................................9

3.5.b Control circuit terminal screw specification ............................................................9

4 Installing the inverter............................................................................................................................................9

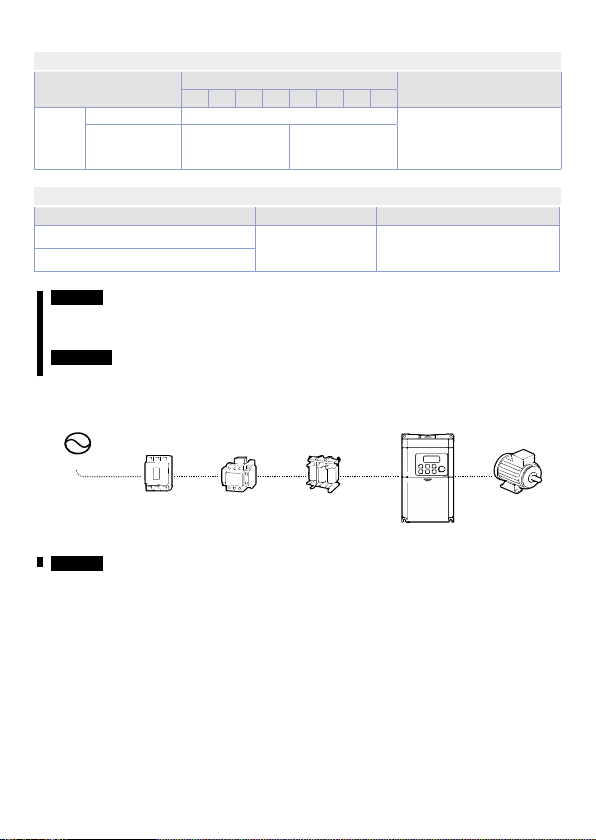

4.1 Basic configuration diagram .........................................................................................................9

4.2 Peripheral devices ...........................................................................................................................10

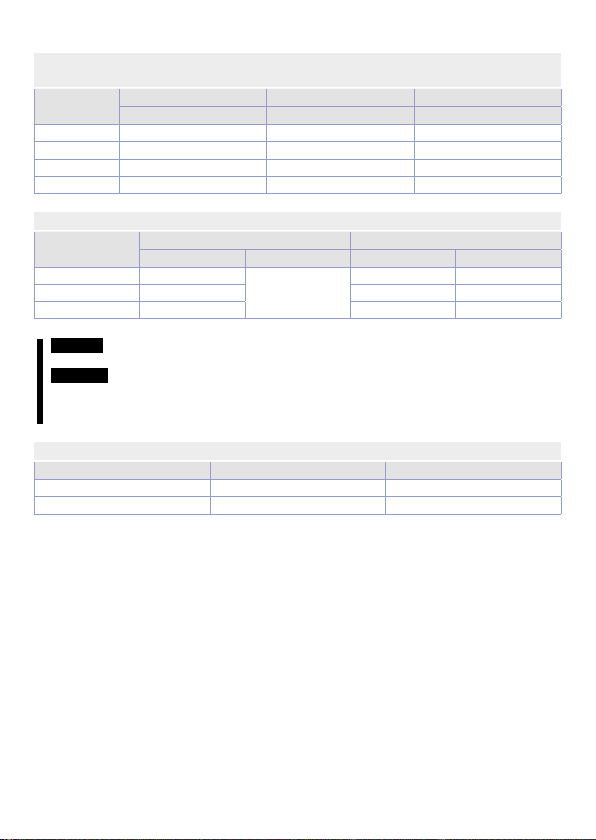

4.2.a Compatible circuit breaker, leakage breaker, magnetic contactor and motor

circuit breaker.....................................................................................................................10

4.2.b Fuse and reactor specifications...................................................................................10

4.2.c Braking resistor specification.......................................................................................10

4.3 Power terminal labels and descriptions .................................................................................11

4.4 Control terminal labels and descriptions...............................................................................12

4.4.a Control board switches...................................................................................................12

4.4.b Connectors...........................................................................................................................12

4.4.c Input terminal labels and descriptions ....................................................................12

4.4.d Output / Communication terminal labels and descriptions............................13

4.5 Disabling the EMC Filter for power sources with asymmetrical grounding............13

5 Learning to perform basic operations..........................................................................................................14

5.1 Operation keys..................................................................................................................................14

5.2 Control menu.....................................................................................................................................14

5.3 Table of functions in operation group ....................................................................................15

6 Technical Specification .......................................................................................................................................16

6.1 Input and output specification ..................................................................................................16

6.2 External dimensions .......................................................................................................................17

6.2.a 0.4~2.2kW (single phase) ...............................................................................................17