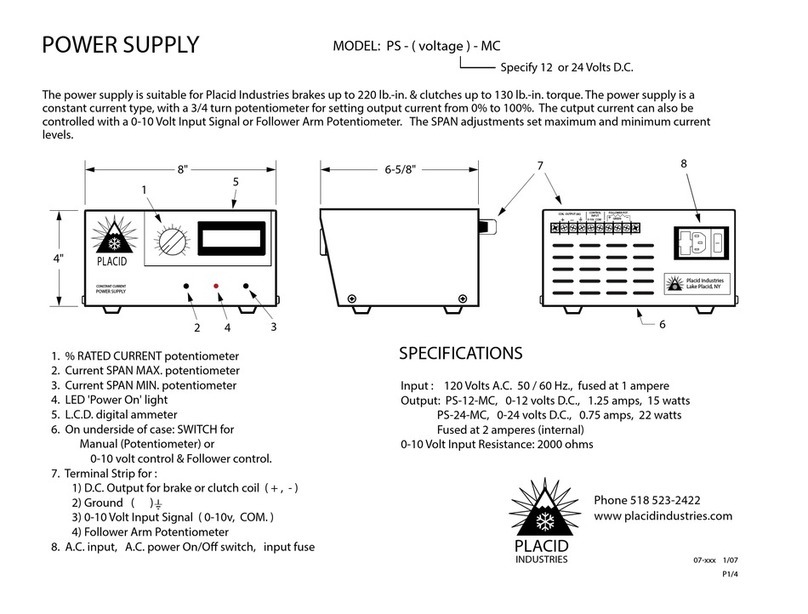

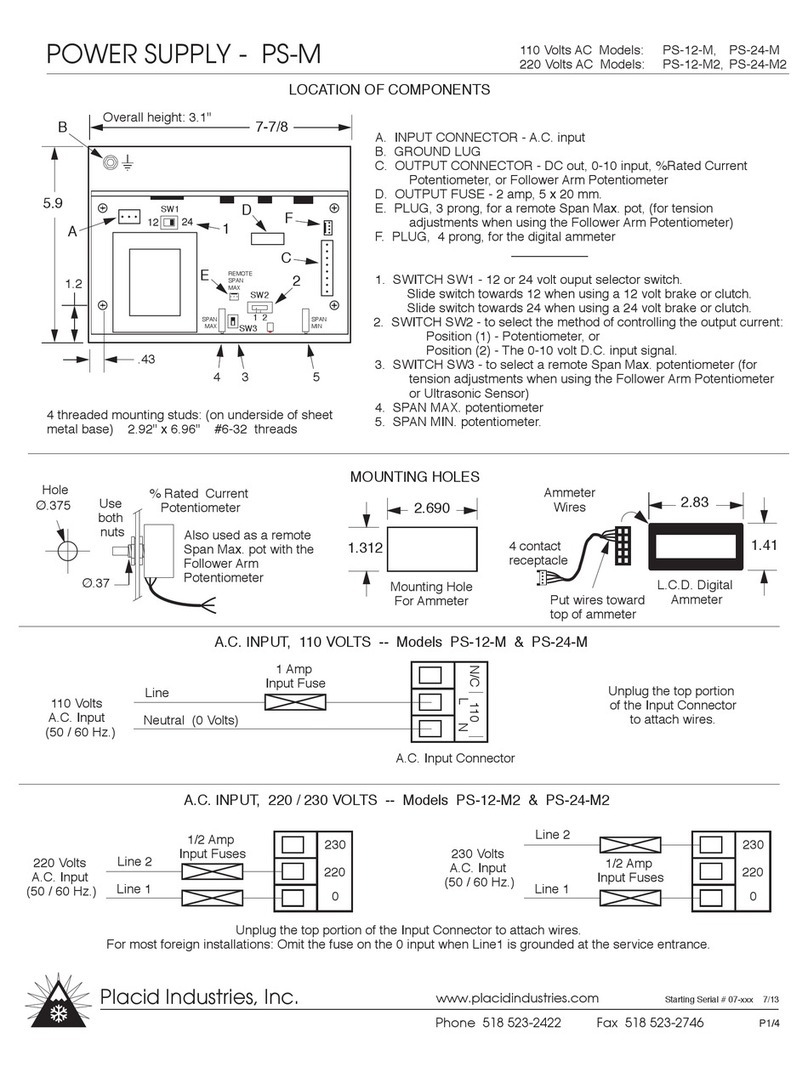

120 Volts A.C. input

PS-12 : 0-12 VDC output

PS-24 : 0-24 VDC output

220 Volts A.C. input

PS-12-2 : 0-12 VDC output

PS-24-2 : 0-24 VDC output

YELLOW

ORANGE

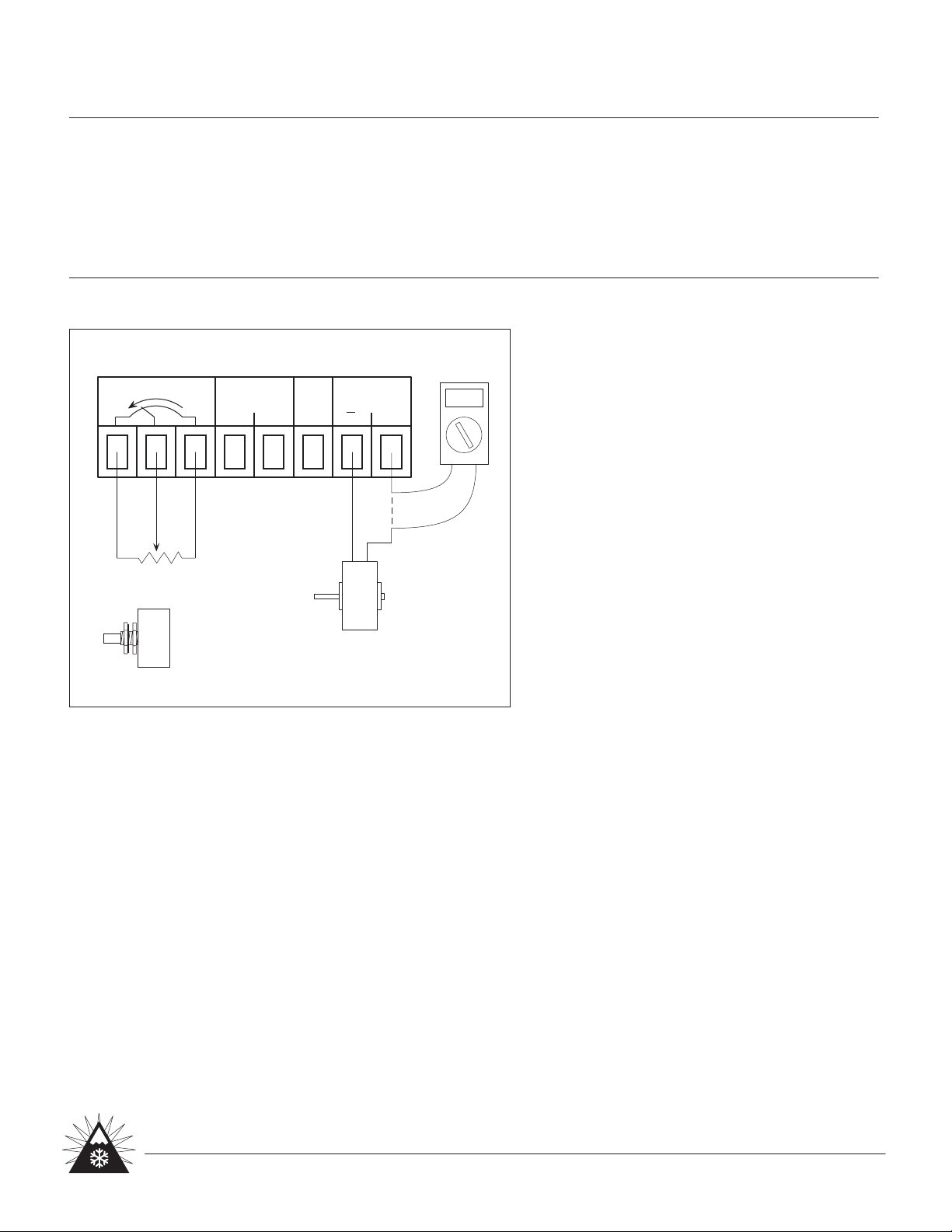

INITIAL SET UP - When Using Manual (Potentiometer) Control:

1) Determine the 100% rated current of the brake (or clutch) from the data sheet, or calculate it from the formula:

100% rated current = (rated voltage) / (coil resistance, ohms)

The rated voltage is listed on the label of the brake or clutch.

2) For safety, disconnect the A.C. power.

3) Set SWITCH SW2 to position 1, so the output current is controlled by the % Rated Current Potentiometer.

Set SWITCH SW3 towards the edge of the circuit board to select the on-board Span Max. Potentiometer.

4) Set the SPAN MAX. potentiometer fully counter-clockwise (for minimum output current).

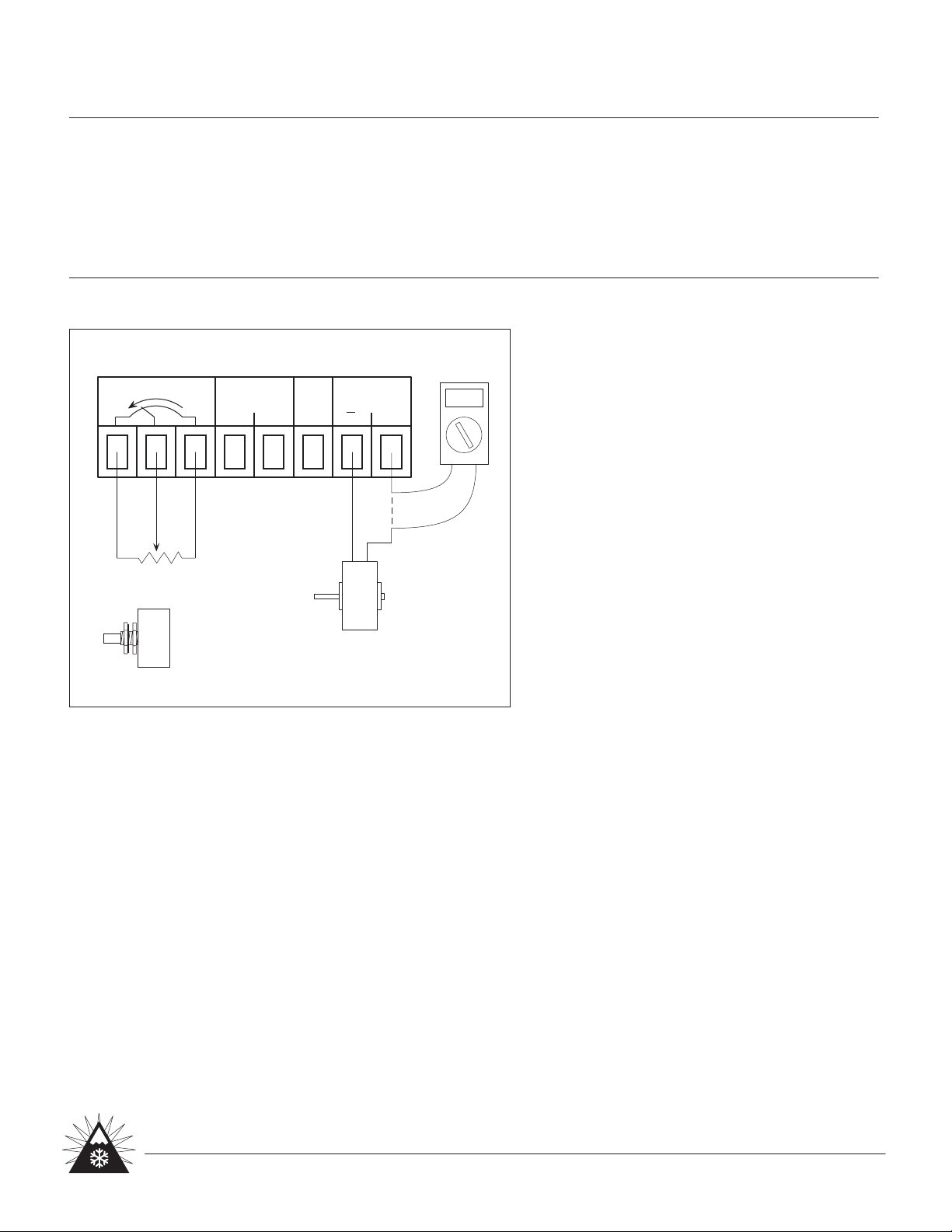

5) Temporarily connect a (customer supplied) ammeter in series with the brake (or clutch). (See wiring diagram.)

6) Connect A.C. power.

7) Set the % RATED CURRENT potentiometer to 100% (for maximum output current).

8) SPAN MAX. - Turn the SPAN MAX. potentiometer clockwise until your ammeter displays the current level

corresponding to the 100% rated current of the brake (or clutch).

9) SPAN MIN. - Set the % RATED CURRENT potentiometer to 10%. Adjust the SPAN MIN. potentiometer until your

ammeter shows the power supply output current is at 10% of rated current.

10) Recheck Steps 7 & 8.

11) Disconnect your (customer supplied) ammeter. Reconnect the brake (or clutch) to Output Connector.

Unplug the top portion of the

Output Connector to attach wires.

AMMETER

WHITE

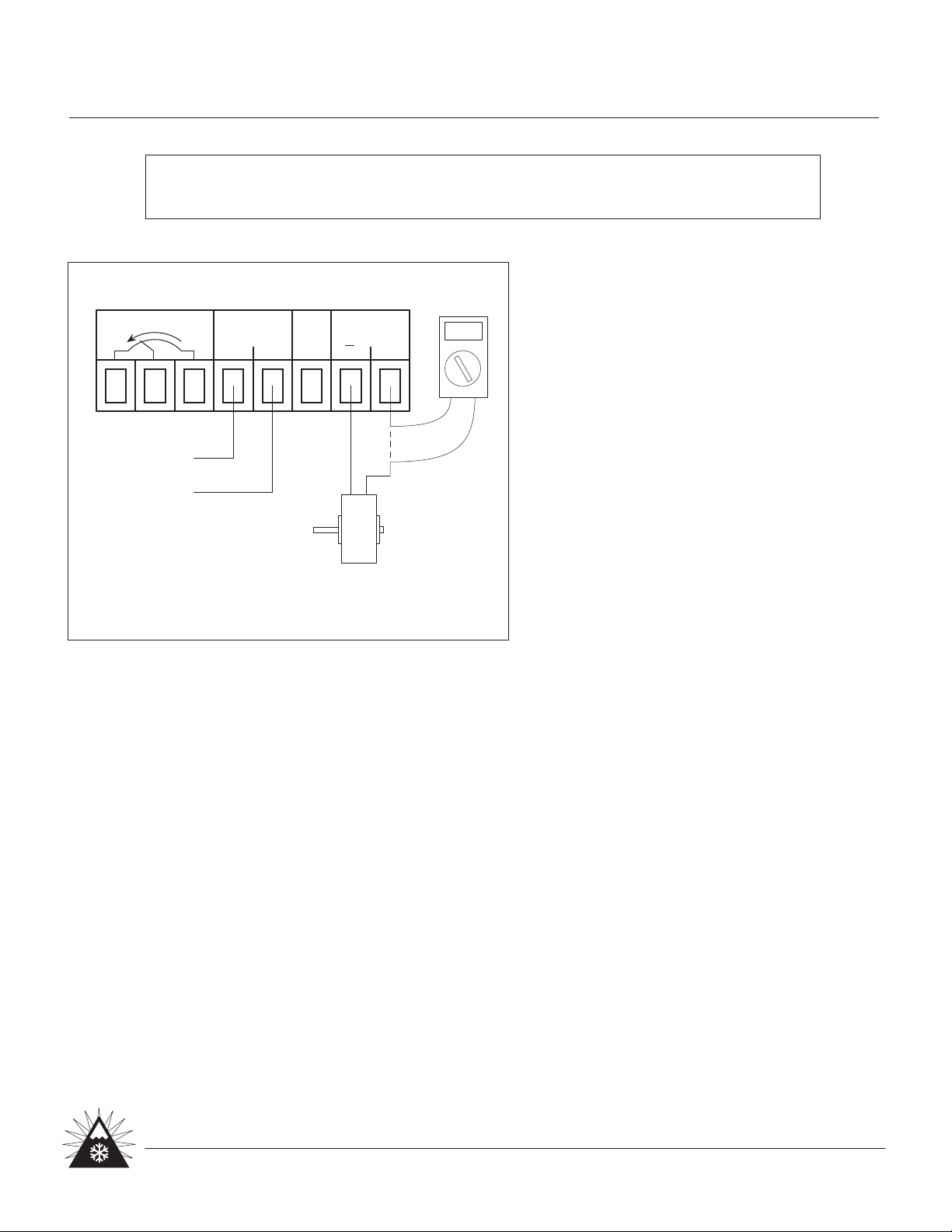

ADJUSTMENTS - When Using Manual

(Potentiometer) Control:

% RATED CURRENT POTENTIOMETER - The

remotely mountable potentiometer controls the

desired output current, and is adjustable from 0%

to 100%. This is used to control output torque.

SPAN MAX. - Sets the maximum output current.

The 10 turn potentiometer is mounted on the

circuit board. Use the miniature plastic

screwdriver provided to make adjustments.

SPAN MIN. - Sets the output current to zero

when the % RATED CURRENT potentiometer is

set to zero. The 10 turn potentiometer is

mounted on the circuit board. Use the miniature

plastic screwdriver provided to make adjustments.

POWER SUPPLY - PS

SPECIFICATIONS

INSTRUCTIONS - MANUAL (Potentiometer) CONTROL

Output Current: D.C., constant current type

12 volt: 1.25 amps

24 volt: 0.75 amps

Output Fuse: 2 amperes, located on circuit board.

0-10 Volt Input Resistance: 2000 ohms

% RATED CURRENT

POTENTIOMETER

BRAKE OR

CLUTCH

(for set-up

only)

P2/4

Placid Industries, Inc.

Phone 518 523-2422 Fax 518 523-2746

www.placidindustries.com Starting Serial # 07-1 1/07

+

OUTPUT

0v 0-10v

0-10 INPUT

NC

% CURRENT POT

+

OUTPUT CONNECTOR