Lift Operation

WARNING! Read all operating instructions before operating the lift. Make sure that all

individuals using the lift have read the instructions and have been made aware of all safety

precautions.

WARNING! Do not exceed the maximum lifting capacity of 400 lbs (181.4 kg). This may result in

damage to the lift or personal injury. Other lift models are available for loads in excess of 400

lbs.

The Swim-Lift® Summit is a water-powered lifting aid designed for use with water systems that

have a 55 PSI rating. This lift will function with as little as 45 PSI water pressure. Optional

pump kits are available for supplying a constant pressure of 55 PSI. Lifting capacities are

based on a continual pressure supply without pressure drops occasionally incurred during peak

demand periods of city water systems. The lifting capacity/pressure ratios are as follows:

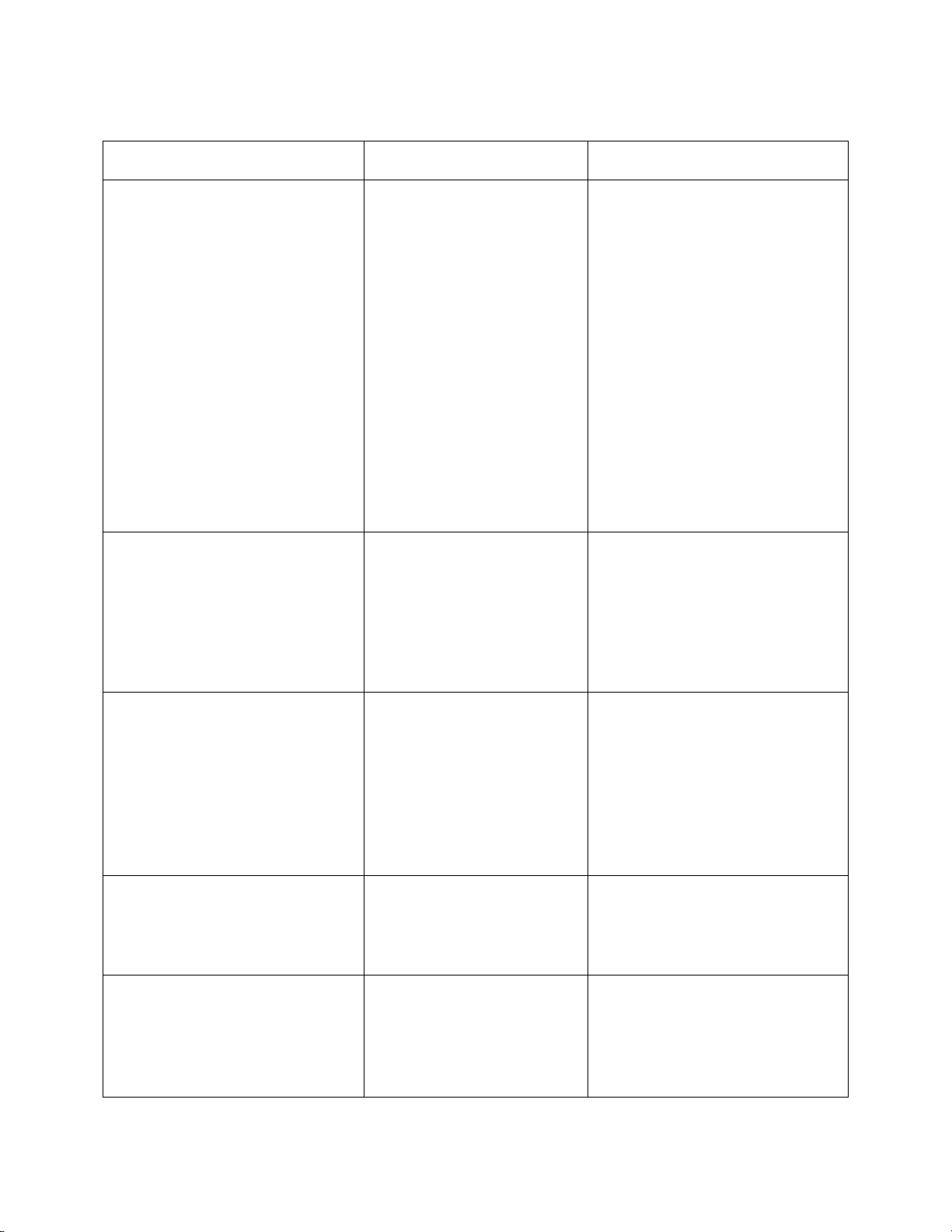

Pressure Lift Capacity

55 PSI 400 lbs.

50 PSI 350 lbs.

45 PSI 300 lbs.

Note: A backflow check valve may be required on this lift to prevent contamination of the

municipal water supply. Please check your state and local codes to see if a backflow check

valve is required.

Lift Preparation:

1. Turn the control valve to the intermediate stop position and attach the water supply hose to

the valve. Turn the water supply on.

2. With no weight on the chair, turn the control valve handle to the up position. Allow the chair

to fully rise.

3. Turn the control valve handle to the down position. Allow the seat to lower to a fully down

position. Repeat steps 2 and 3 until a smooth operation is attained. This process purges

the air from the system and should not take more than 5 to 7 cycles to complete.

Lift Operation:

1. Lift operation is controlled through the use of the control valve. The valve handle turned

clockwise will lower the chair, and turned counter-clockwise will raise the chair. The chair

will stop at any point along its travel if the valve handle is turned to an intermediate position.

Excessive force is not required to turn the valve handle. Instruct all operators on proper use

of the control valve prior to operation of the lift.

2. The outer chair arm flips up and back for ease of transfer from a wheelchair to the lift seat.

In addition, the stationary arm on the inside of the chair may assist in transferring. Use of

the seatbelt is recommended for all users. To facilitate safe loading and unloading of

5

800.791.8056 ▪www.spectrumproducts.com