plumBOSS Australia Head Oce - Ph: 1300 331 141 | Fax: 1300 764 510 | E: info@plumboss.com.au

exactCUT 170/170E/220E Operating Instructions

Safety

l. Check the operation of the lower guard. If the guard

and the spring are not operating properly, they must

be serviced before use. Lower guard may operate

sluggishly due to damaged parts, gummy deposits,

or a build-up of debris.

m. Do not reach into the saw dust ejector with your

hands. They could be injured by rotating parts.

n. Do not work overhead with the saw. In this manner

you do not have suf cient control over the power

tool.

o. Do not operate the power tool stationary. It is not

designed for operation with a saw table.

p. Do not use high speed steel (HSS) saw blades. Such

saw blades can easily break.

q. When working with the machine, always hold it rmly

with both hands and provide for a secure stance. The

power tool is guided more secure with both hands.

r. Secure the workpiece. A workpiece supported by

pipe holders is held more secure than by hand.

s. Always wait until the machine has come to a

complete stop before placing it down. The tool insert

can jam and lead to loss of control over the power

tool.

t. Never use the machine with a damaged cable. Do

not touch the damaged cable and pull the mains plug

when the cable is damaged while working. Damaged

cables increase the risk of an electric shock.

Additional specic safety rules

The pipe saw must never be used in the following

cases, if:

• There is water or another liquid, explosive gases or

poisonous chemicals inside the pipe to be cut.

• The power switch is faulty.

• The power cable is faulty,

• The blade is bent.

• The blade is blunt or in poor condition.

• The plastic components are cracked or have parts

missing.

• The gripper unit is not properly tightened around the

pipe or if it is warped.

• The blade guard cover or moving blade guard has

been damaged or removed from the machine.

• The locking mechanisms do not work properly

(UNLOCK-button).

• The pipe saw has become wet.

When using the pipe saw, the following factors

must always be taken into consideration:

• Support tubes to minimise the risk of blade pinching.

• Ensure that the pipe to be cut is empty.

• Ensure that the blade is correctly installed.

• Ensure that the diameter and thickness of the blade

are suitable for the pipe saw and that the blade is

suitable for the rpm-range of the machine.

• Never use sideways force to stop the blade, always

allow the blade to stop freely.

• Check the attachments of the blade guards.

• Never use excessive force when using the pipe saw.

• Never use the pipe saw to lift the pipe while it is still

attached to the pipe.

• Avoid overloading the electric motor.

• Always follow the safety and operating instructions

and current regulations. Functional Description Read

all safety warnings and all instructions. Failure to

follow the warnings and instructions may result in

electric shock, re and/or serious injury.

Intended Use

The PipeCut 170/170E/220E pipe saw is intended

for use as a pipe tter’s tool at the installation site.

The PipeCut 170/170E/220E pipe saw can only be

used to cut round pipes, with a diameter of 15-170

mm (0,6”-6”) models 170 and 170E,15-220 mm (0,6”-

8,6”) model 220E and a maximum wall thickness of

6 mm (0,23”) (model170) and 8 mm (0,31”) (models

170E and 220E) with steel and other ferrous and non-

ferrous materials and 0 55” (14 mm) with plastics.

The PipeCut 170/170E/220E pipesaw can be used to

cut allnormalpipe materials, such as steel, stainless

steel, cast iron,copper aluminium and plastic. PipeCut

170/170E/220E pipe saw is intended for short,

intermittent use. The machine may be loaded for 2,5

minutes during a 1Q-minute period (83 25 %). PipeCut

170/170E/220E pipe saw is not intended for use in

industrial production. Use pipe holders to support pipe.

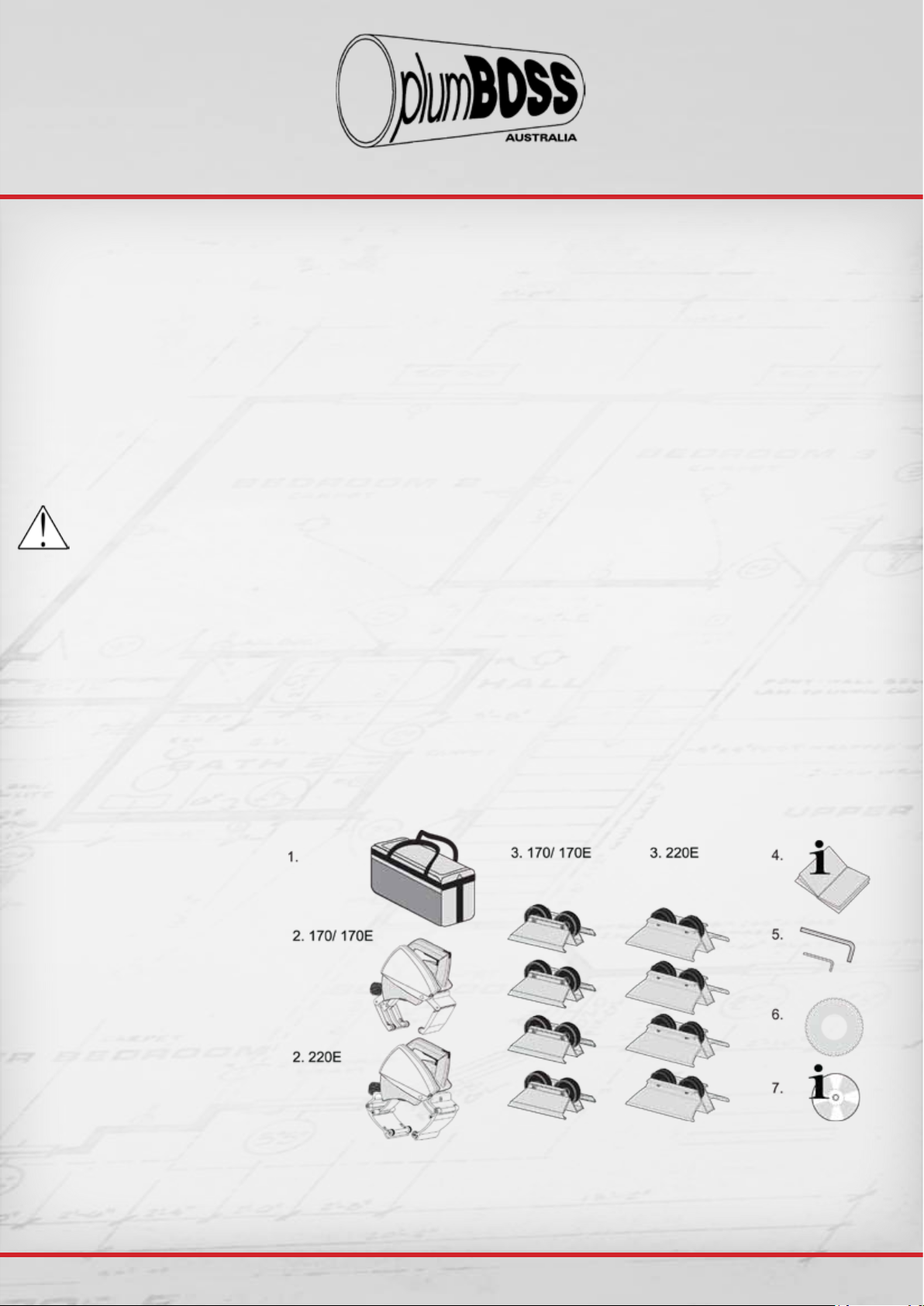

Product Features

While reading the operating instructions, unfold the

graphics page for the machine and leave it open.

This page is folded under the cover of this manual

(page 3). The following numbering of the product

features refers to this illustration.