©2015 POISON SPYDER CUSTOMS 951-849-5911•WWW.POISONSPYDER.COM

INSTALLATION INSTRUCTIONS INST-17-17-021_A

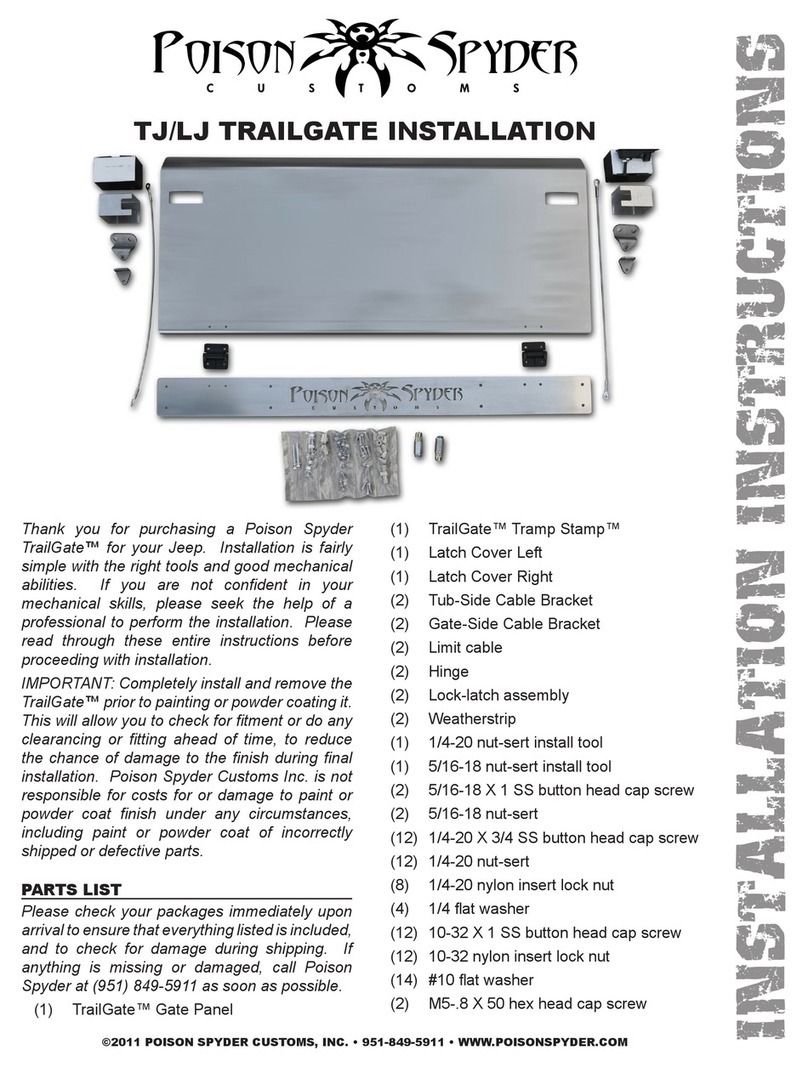

JK BFH™ II

Rear

Bumper

IMPORTANT: Thank you for purchasing this Poison Spyder product. Please read through this entire document before proceeding with installation. If you are not

confident in your mechanical skills, please seek the help of a professional to perform the installation. Check your packages immediately upon arrival to ensure that

everything listed is included, and to check for damage during shipping. If anything is missing or damaged, or if you need technical assistance with any aspect of

this installation, call Poison Spyder at (951) 849-5911 as soon as possible. This document last updated November 2015.

APPLICATIONS

These installation instructions apply to the following

Poison Spyder products:

17-17-021-D JK BFH™ II Rear Bumper - Tabs

17-17-021-DL JK BFH™ II Rear Bumper - Tabs - Lights

17-17-040-D JK BFH™ II Rear Bumper - Hitch - Tabs

17-17-040-DL

JK BFH™ II Rear Bumper - Hitch - Tabs - Lights (Shown)

PARTS LIST

Please check your packages immediately upon arrival

to ensure that everything listed is included, and to

check for damage during shipping. If anything is

missing or damaged, call Poison Spyder at (951) 849-

5911 as soon as possible.

(1) JK BFH™ II Rear Bumper

(1) JK BFH™ II Rear Frame Cut Template

(1) JK BFH™ II Rear Bumper Hardware Kit

PN: HWKIT-17-17-020 includes:

(4) 3/8-16 X 1 Gr8 hex head cap screw

(4) 3/8 SAE Hardened Flat Washer

(2) 3/8-16 Extruded U-Nut Clip

(2) 3/8-16 Serrated Flange Nut

TOOLS NEEDED

• Reciprocating saw with bi-metal blade OR pneumatic cut-

off wheel OR plasma cutter OR similar tool for cutting metal

• Mechanic’s tool set with an assortment of wrenches,

sockets, etc.

• Angle grinder

• Drill motor with 1/4” and 1/2” drill bits

• Fine-tip felt marker

• Primer and paint

BEFORE YOU BEGIN

The Poison Spyder Customs BFH II Rear bumper

comes as unpainted, bare steel. You will want to

either powder coat or paint the bumper prior to

nal installation, however it is recommended that a

complete installation be performed rst, with the bare/

unpainted bumper to ensure tment without damaging

the paint or powder coat nish. Poison Spyder

Customs is NOT RESPONSIBLE for paint or powder

coating costs, damage to paint or powder coating,

or costs associated with inadvertently painting or

powder coating components that are defective or were

shipped or assembled in error. It is the customer’s

responsibility to pre-install and verify that all parts are

correct prior to paint or powder coat.

IMPORTANT: It is highly recommended to install

the Poison Spyder JK BFH II Rear Crossmember

in conjunction with this bumper. However, at the

installer’s discretion, the JK BFH II Rear Bumper

may be installed by itself, without the replacement

crossmember. Note that this will leave the Jeep without

the full strength of an intact rear crossmember, and the

installer does so at his/her own risk. Poison Spyder

makes no warranty for the integrity of the Jeep’s frame

on JK BFH II Rear Bumper installations where the JK

BFH II Rear Crossmember was not properly installed.

INSTALLATION PROCEDURE

NOTE: The rst 10 steps of the instructions provided

here are for those who intend to install this bumper

WITHOUT the Poison Spyder JK BFH II Rear

Crossmember. If you ARE installing the JK BFH II Rear

Crossmember, install it rst, following the instructions

that came with the crossmember, then skip past the

steps that are duplicated here (marking and cutting

the crossmember).

1. Park the Jeep on a flat, level surface and set the

parking brake. You will want to wear eye protection

beyond this point in time.