TABLE OF CONTENTS

CHAPTER 1 ................................................................................................................................. 1

GENERAL INFORMATION.......................................................................................................... 1

TERMS LEFT AND RIGHT................................................................................................................................ 1

NOTES, CAUTIONS AND WARNINGS ............................................................................................................ 1

TROUBLESHOOTING / DIAGNOSTIC GUIDE................................................................................................ 2

TOOLS ................................................................................................................................................................ 4

SPECIFICATIONS.............................................................................................................................................. 4

TABLE 1: ELECTRICAL SPECIFICATIONS.................................................................................................. 4

TABLE 2: PARTS............................................................................................................................................. 4

GENERAL WARRANTY INFORMATION.......................................................................................................... 6

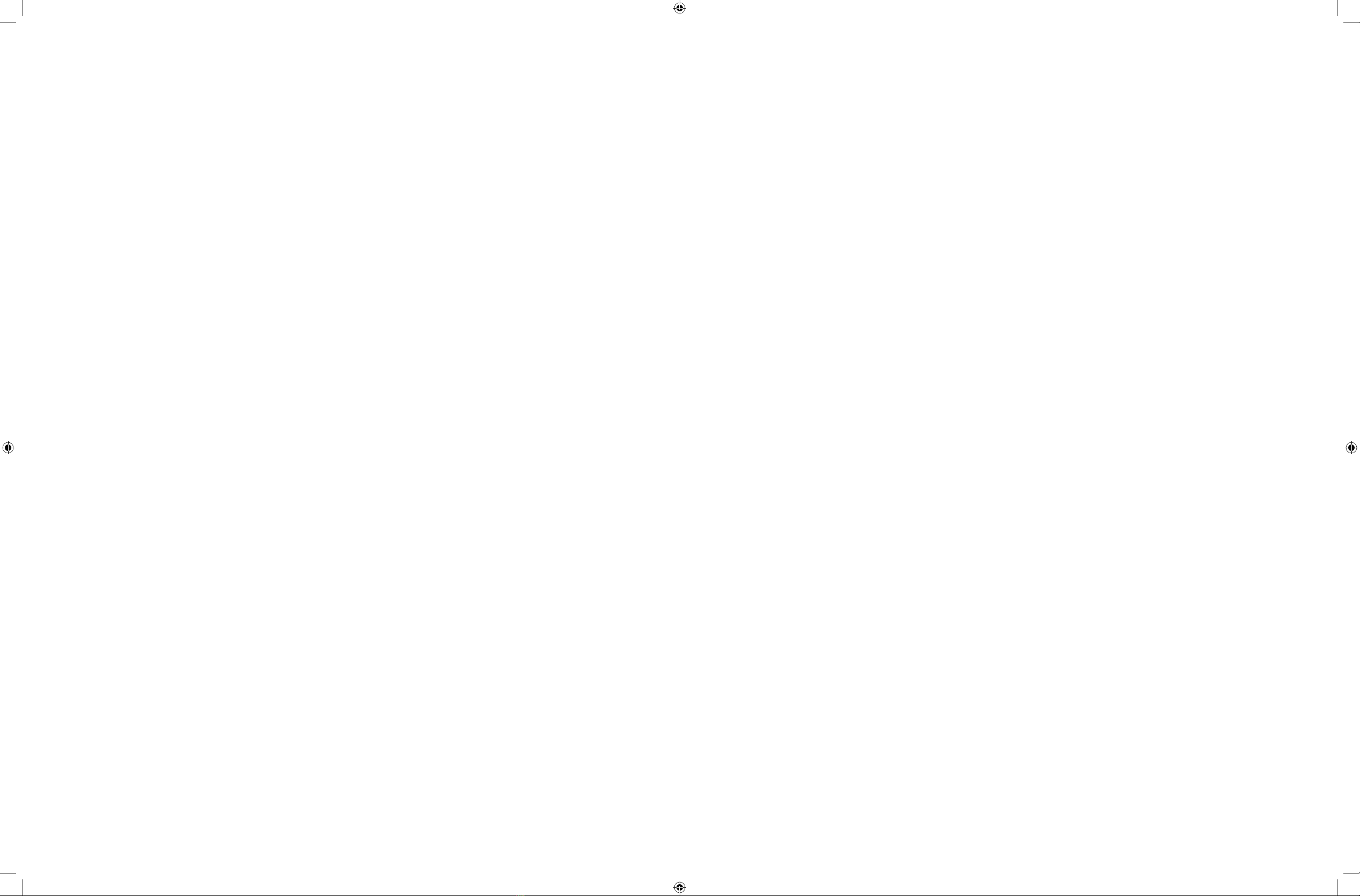

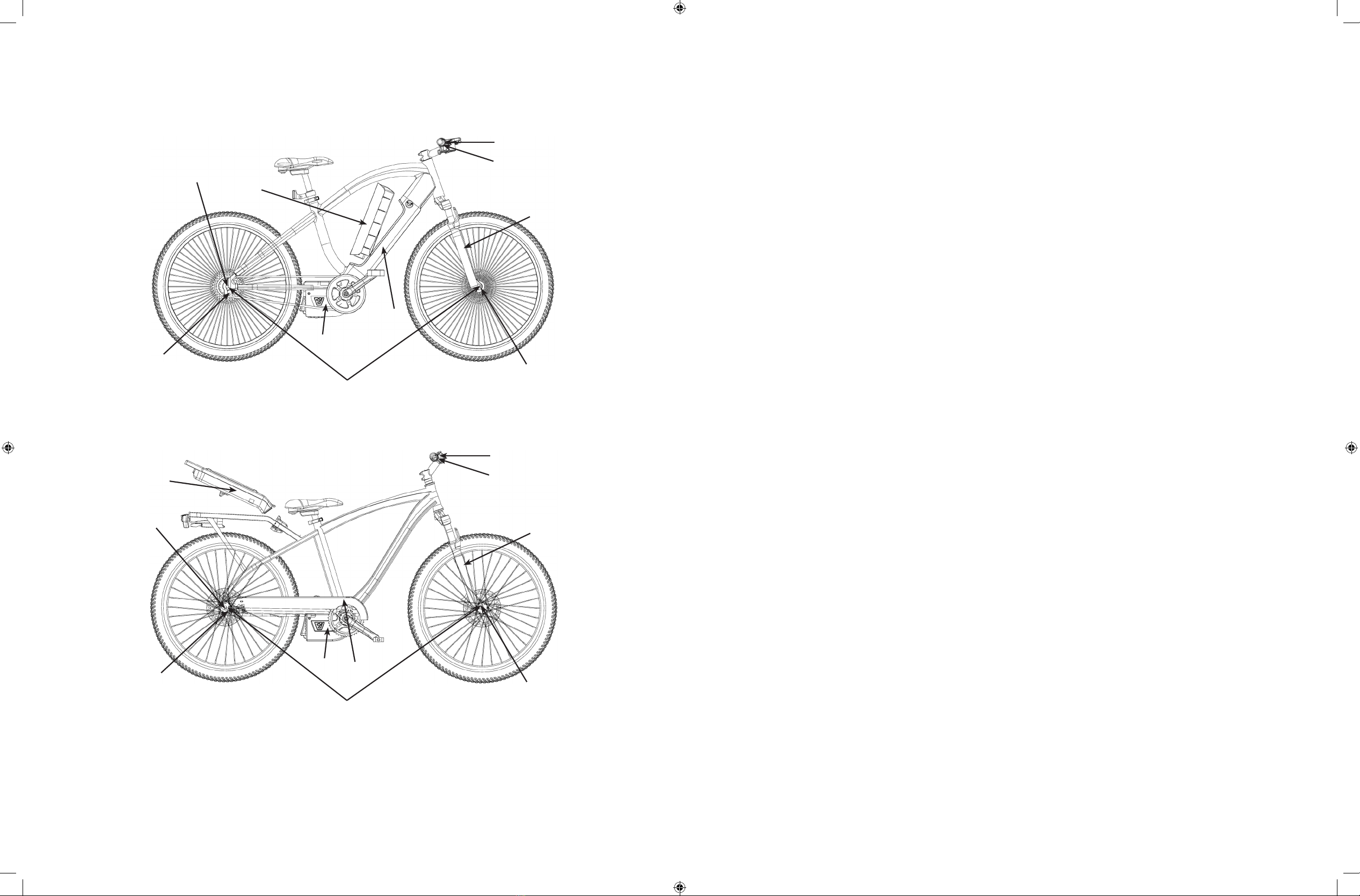

COMPONENTS TO BECOME FAMILIAR WITH WHICH ARE COVERED UNDER WARRANTY............ 6

BICYCLE OVERVIEW.................................................................................................................................... 6

WARRANTY PROGRAM DETAILS................................................................................................................... 7

MOTOR SYSTEM COMPONENT WARRANTY........................................................................................... 7

NON-ELECTRIC COMPONENT WARRANTY............................................................................................. 7

SERVICING OF PARTS ..................................................................................................................................... 7

CHAPTER 2 ................................................................................................................................. 8

STEERING AND SUSPENSION................................................................................................. 8

HANDLEBAR REPLACEMENT......................................................................................................................... 8

REMOVAL....................................................................................................................................................... 8

INSTALLATION ............................................................................................................................................... 9

HANDLEBAR STEM ......................................................................................................................................... 9

REMOVAL....................................................................................................................................................... 9

INSTALLATION ............................................................................................................................................... 10

FRONT FORK REMOVAL/INSTALLATION....................................................................................................... 11

REMOVAL....................................................................................................................................................... 11

INSTALLATION ............................................................................................................................................... 12

CHAPTER 3 ................................................................................................................................. 13

BRAKES ....................................................................................................................................... 13

BRAKE LEVER REMOVAL/INSTALLATION..................................................................................................... 13

REMOVAL....................................................................................................................................................... 13

INSTALLATION .............................................................................................................................................. 13

BRAKE CABLE INNER WIRE .......................................................................................................................... 14

REMOVAL....................................................................................................................................................... 14

INSTALLATION ............................................................................................................................................... 14

BRAKE CALIPER REMOVAL/INSTALLATION ................................................................................................. 16

BRAKE CALIPER REMOVAL ........................................................................................................................ 16

INSTALLATION ............................................................................................................................................... 16

BRAKE PAD REPLACEMENT........................................................................................................................... 16

BRAKE DISC REMOVAL/INSTALLATION ........................................................................................................ 17

CHAPTER 4 ................................................................................................................................. 18

SHIFTER AND DERAILLEUR..................................................................................................... 18

REMOVAL....................................................................................................................................................... 18

INSTALLATION ............................................................................................................................................... 18

SHIFTER CABLE INNER WIRE REMOVAL/INSTALLATION .......................................................................... 19

REMOVAL....................................................................................................................................................... 19

INSTALLATION ............................................................................................................................................... 20

DERAILLEUR ..................................................................................................................................................... 21

DERAILLEUR LUBRICATION ....................................................................................................................... 21

DERAILLEUR ADJUSTMENT....................................................................................................................... 21

SETTING CABLE TENSION.......................................................................................................................... 22

DERAILLEUR INSTALLATION....................................................................................................................... 22

CHAPTER 5 ................................................................................................................................. 23

CHAIN AND CRANKSET ............................................................................................................ 23

CHAIN................................................................................................................................................................. 23

INSPECTION.................................................................................................................................................. 23

CHECKING CHAIN LENGTH ........................................................................................................................ 23

REMOVAL....................................................................................................................................................... 24

CLEANING...................................................................................................................................................... 24

INSTALLATION ............................................................................................................................................... 24

LUBRICATION ................................................................................................................................................ 25

CRANK ARM ...................................................................................................................................................... 25

REMOVAL....................................................................................................................................................... 25

INSPECTION.................................................................................................................................................. 26

INSTALLATION ............................................................................................................................................... 27

CHAINRING........................................................................................................................................................ 27

REMOVAL....................................................................................................................................................... 27

INSTALLATION ............................................................................................................................................... 27

CHAINRING WOBBLE CHECK......................................................................................................................... 28

PEDAL ............................................................................................................................................................... 28

REMOVAL....................................................................................................................................................... 28

INSTALLATION ............................................................................................................................................... 28

BOTTOM-BRACKET CARTRIDGE................................................................................................................... 29

REMOVAL....................................................................................................................................................... 29

INSTALLATION ............................................................................................................................................... 30

CHAPTER 6 ................................................................................................................................. 31

MOTOR SYSTEM ........................................................................................................................ 31

TROUBLESHOOTING DIAGNOSTIC GUIDE.................................................................................................. 31

ServiceManual_101212.indd 2-3 10/12/2012 12:25:43 AM