8

OPERATING INSTRUCTIONS

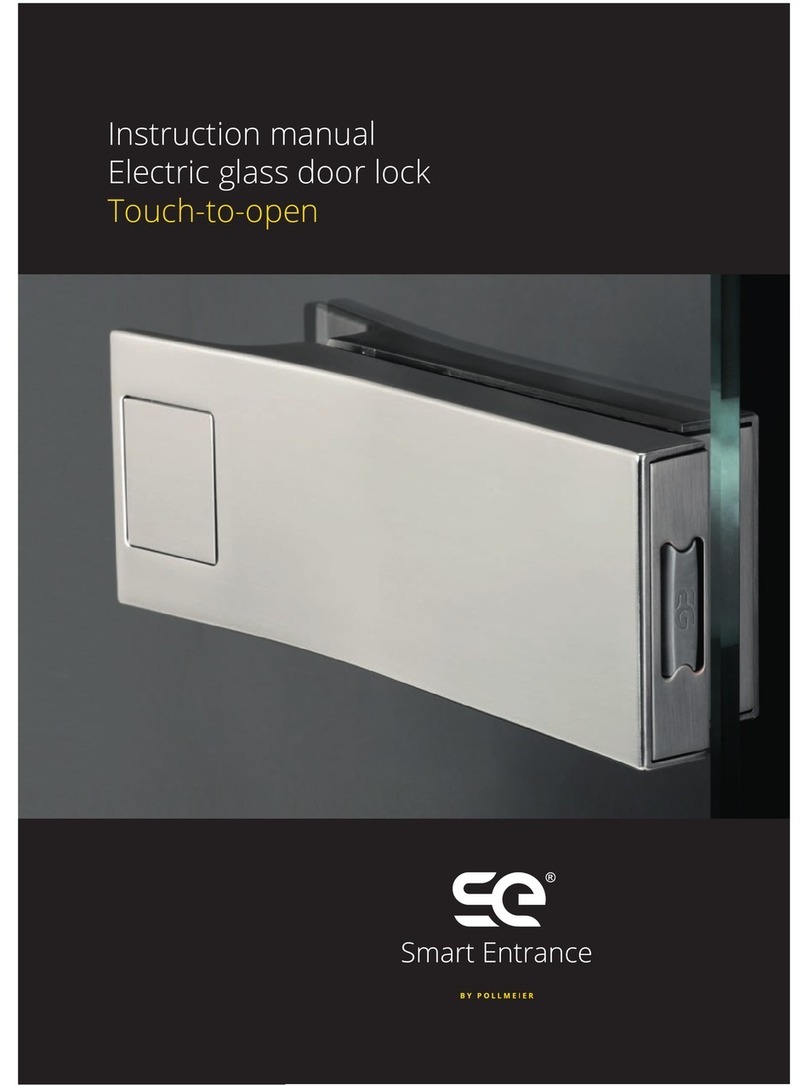

Touch to open electric mortise lock

3 Security

3.1 Intended Use

– The lock is designed for occasional use in private interior rooms by persons who handle

the technology carefully.

– The lock is exclusively designed for fitting in single-leaf wooden room doors, but not in

combination with steel frames.

– The door weight must not exceed 100 kg.

– Only use handles licensed by Baugruppentechnik Pollmeier GmbH in conjunction with the

electric mortise lock as the function cannot otherwise be guaranteed (see section 7).

– Always use the same handle design on both sides of the door.

– Only use the lock in undamaged condition without defects. Exclusively use the supplied

batteries, or equivalent (type AAA 1.5 V micro alkaline batteries).

The A-rated emitted sound pressure level is less than or equal to 70 dB(A). There is no risk

from noise.

The maximum effective value of the weighted acceleration to which the entire body is

exposed is less than 0.5 m/s². The overall vibration value to which the upper body limbs are

exposed is less than 2.5 m/s². Thus, there is no risk due to vibration.

2.3 Function

When the door is closed, the latch is pulled out of the lock by the magnetic strike plate and

snaps into place in the strike plate.

When the door handle is touched with a part of the body (preferably the hand), the locking

part (latch) on the lock is electrically retracted. The motor overcomes the magnetic

attraction force and pulls the latch out of the strike plate. The door can be open by pushing

or pulling.