Instruction manual for installation, operation and use

- 2 -

Technical characteristics of the product

Marking

Conformity marking

DN/NPS

PN/CLASS

PT [bar]

TS [°C]

Date of pressure test

Serial number/ year of production

Category acc. to PED

Category of fluid Liquid

Gas

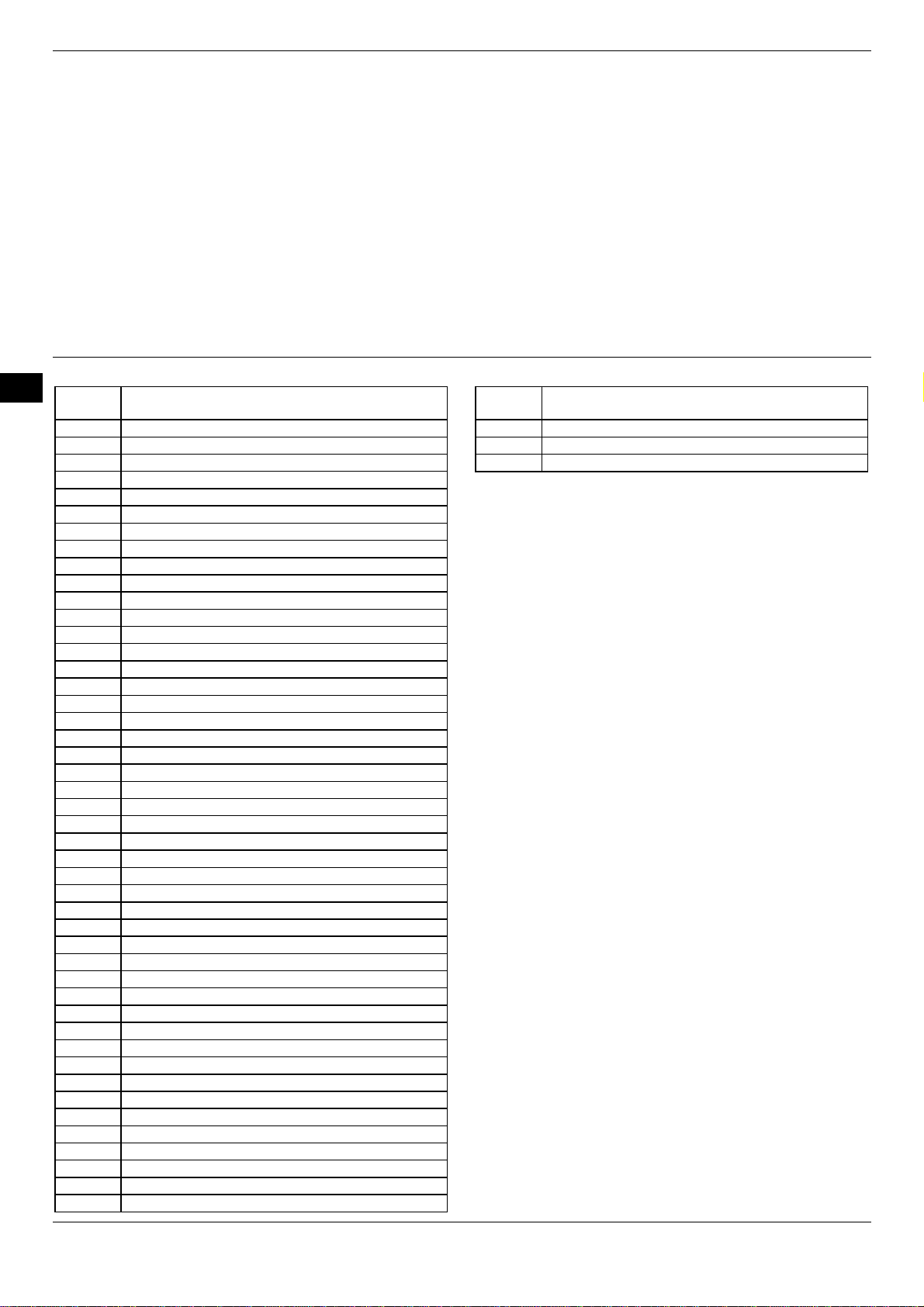

List of contents:

1. Introduction

2. General warnings

3. Requirements for equipment used in potentially explosive

atmosphere according to Directive 2014/34/UE (ATEX)

4. Conditions of safe use

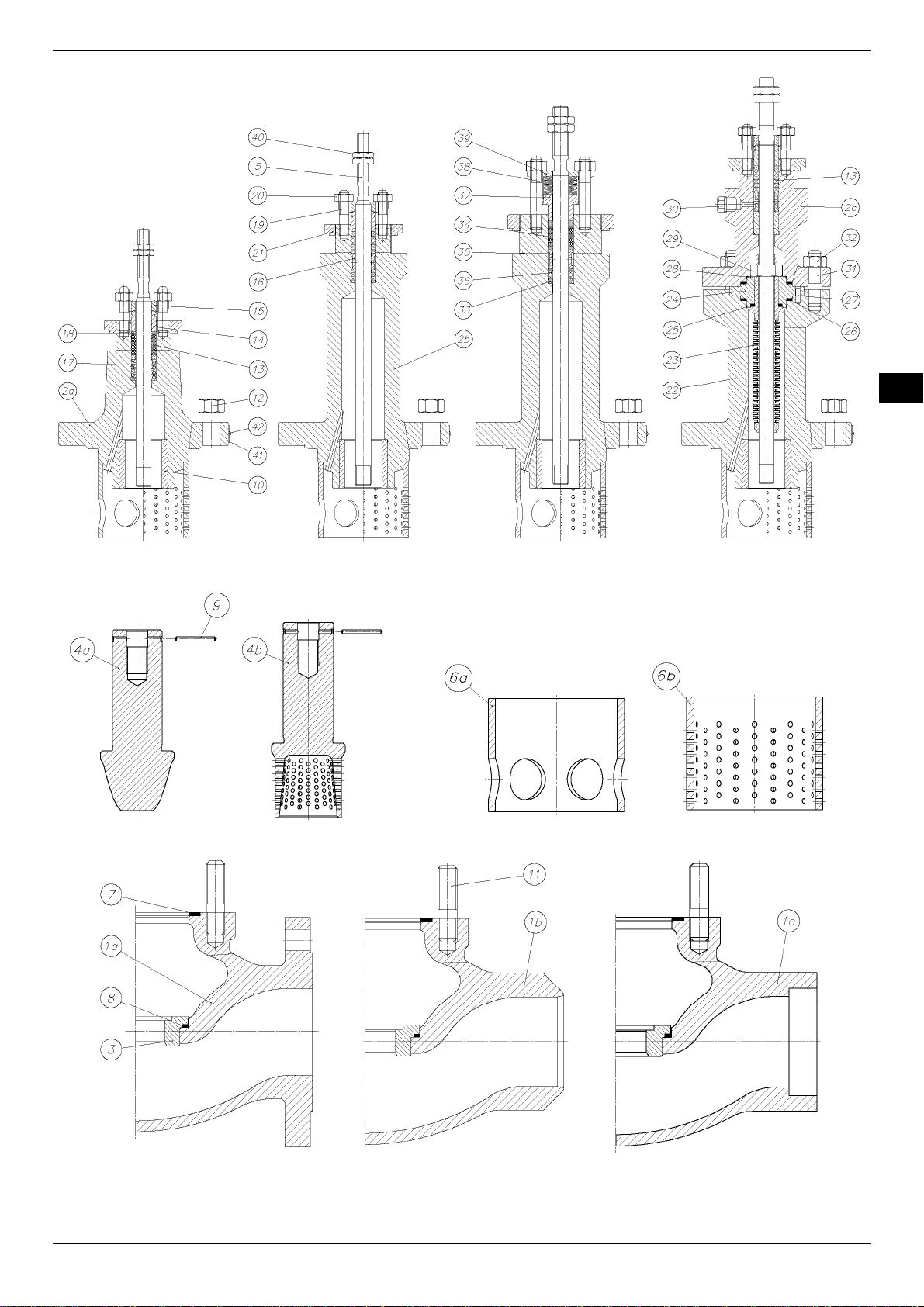

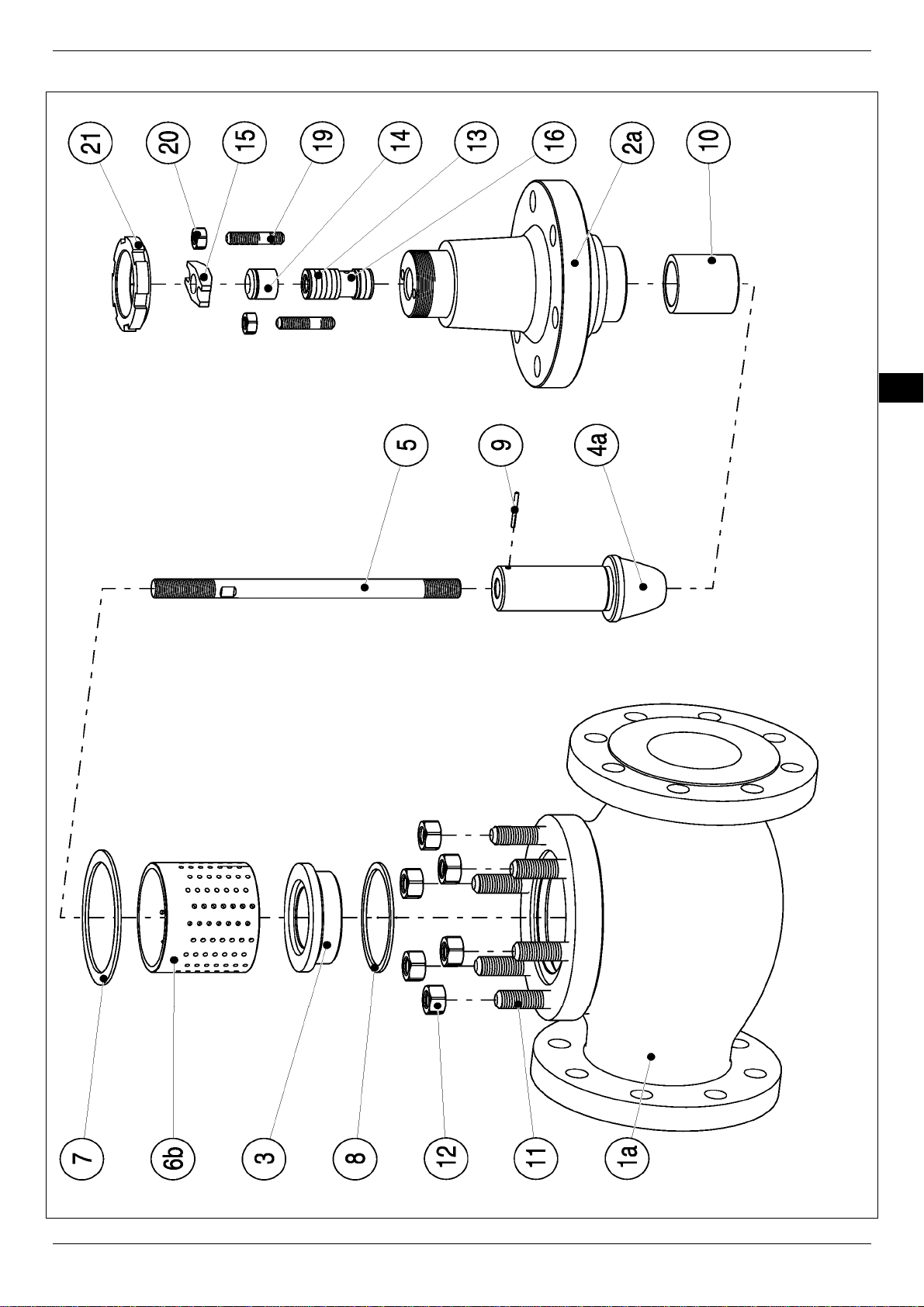

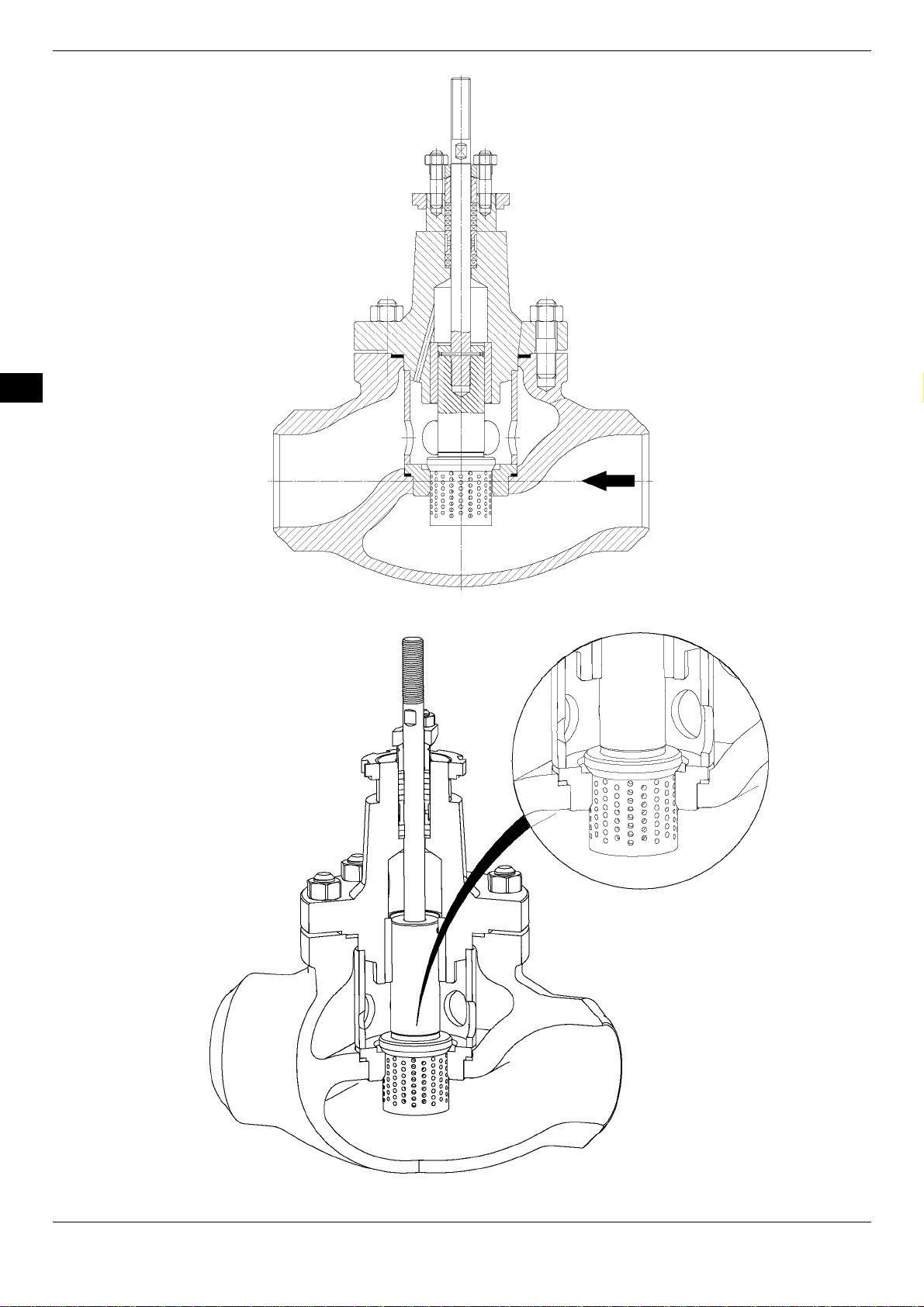

5. Design and operating principle

6. Dimensions

7. Normal operating conditions

8. Storage and transport

9. Installation

10. Start-up and assembly with drives

11. Service

12. Repair

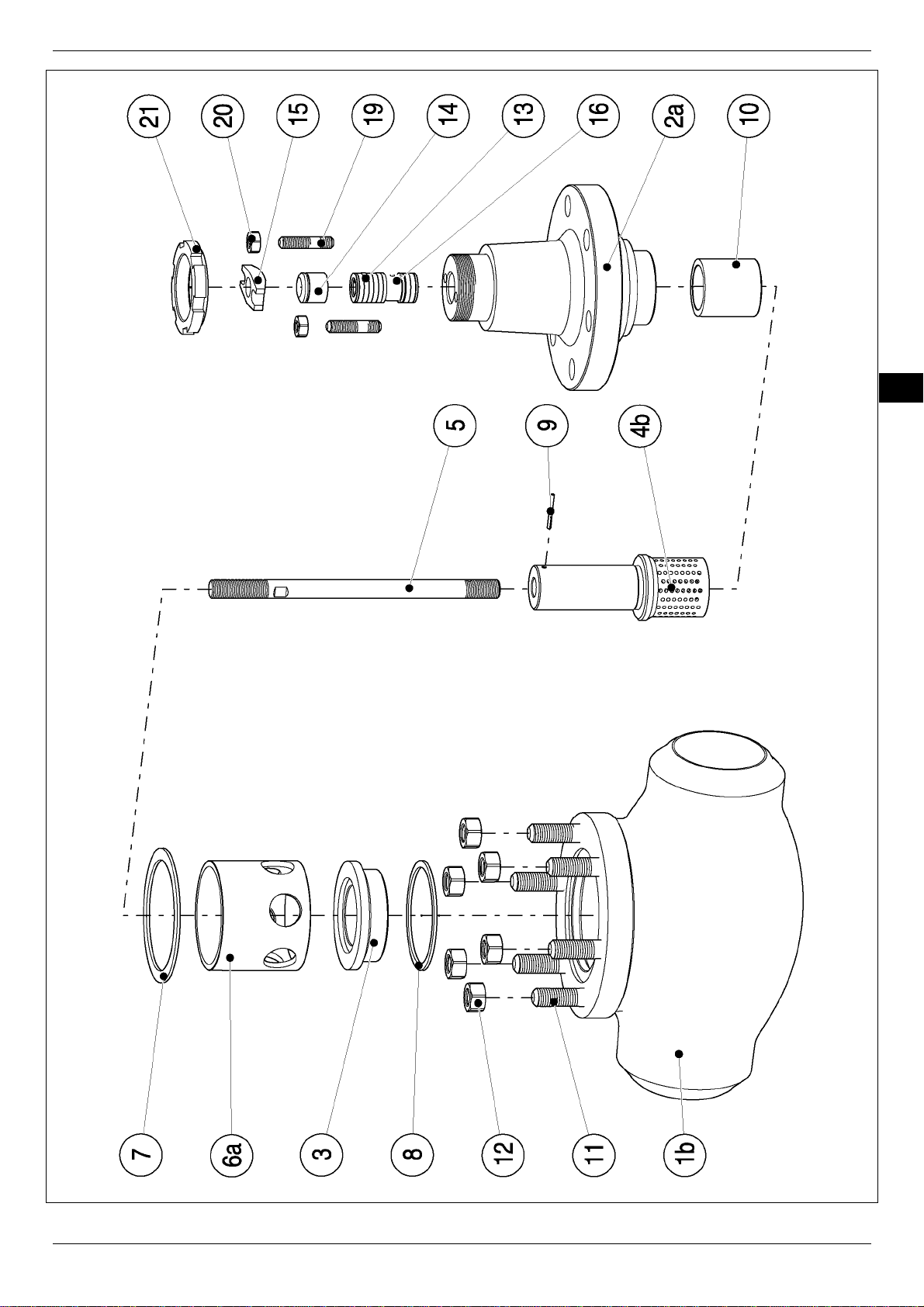

13. List of spare parts

14. Product disposal

15. Troubleshooting

1. Introduction

The Instruction manual for installation, operation and use is

intended for products designed and manufactured according to

the requirements of the ISO 9001 quality management system,

Pressure Equipment Directive (PED) 2014/68/EU, ATEX

directive 2014/34/UE and AD2000 Merkblatt regulations,

intended for installation on pipelines.

2. General warnings

WARNING

Prior to the product installation and use, read carefully

and follow the Instruction. All activities related to

installation, operation and use of the product have to be

carried out by appropriatly trained and skilled staff.

"POLNA" S.A., hereinafter also called the

manufacturer

,

has highly qualified service staff able to assist in

installation, maintenance and repairs of our valves.

The warning symbol in the Instruction means that

the content (of a WARNING or CAUTION message) is very

important due to safety reasons.

The product is intended for installation on pipelines.

Any other use has to be agreed with "POLNA" S.A. at the

stage of ordering of the product. If in doubt, contact

"POLNA" S.A. for explanation before performing any

further actions.

If the product is installed and maintained correctly, its

most ergonomic operation is ensured. However, it is

necessary to follow the requirements given in the

Instruction.

The product has to be installed and maintained

according to domestic and industrial regulations and

instructions.

The Instruction does not cover all cases and incidents

that may occur during installation, use and maintenance or

local safety regulations.

The content of the Instruction is of informative nature

and is considered to be true. The company reserves the

right to modifications, improvements and changes in the

technical data without notice.

"POLNA" S.A. is not liable for a valve selection made

by the buyer on his own or for operation and use of the

valve against its intended use. Failing to comply with the

provisions of this document, in particular when it comes to

use, repairs etc., will result in losing the guarantee and

warranty.

Z1A type control valves (Edition_

10/2022

)

EN