Getting Started

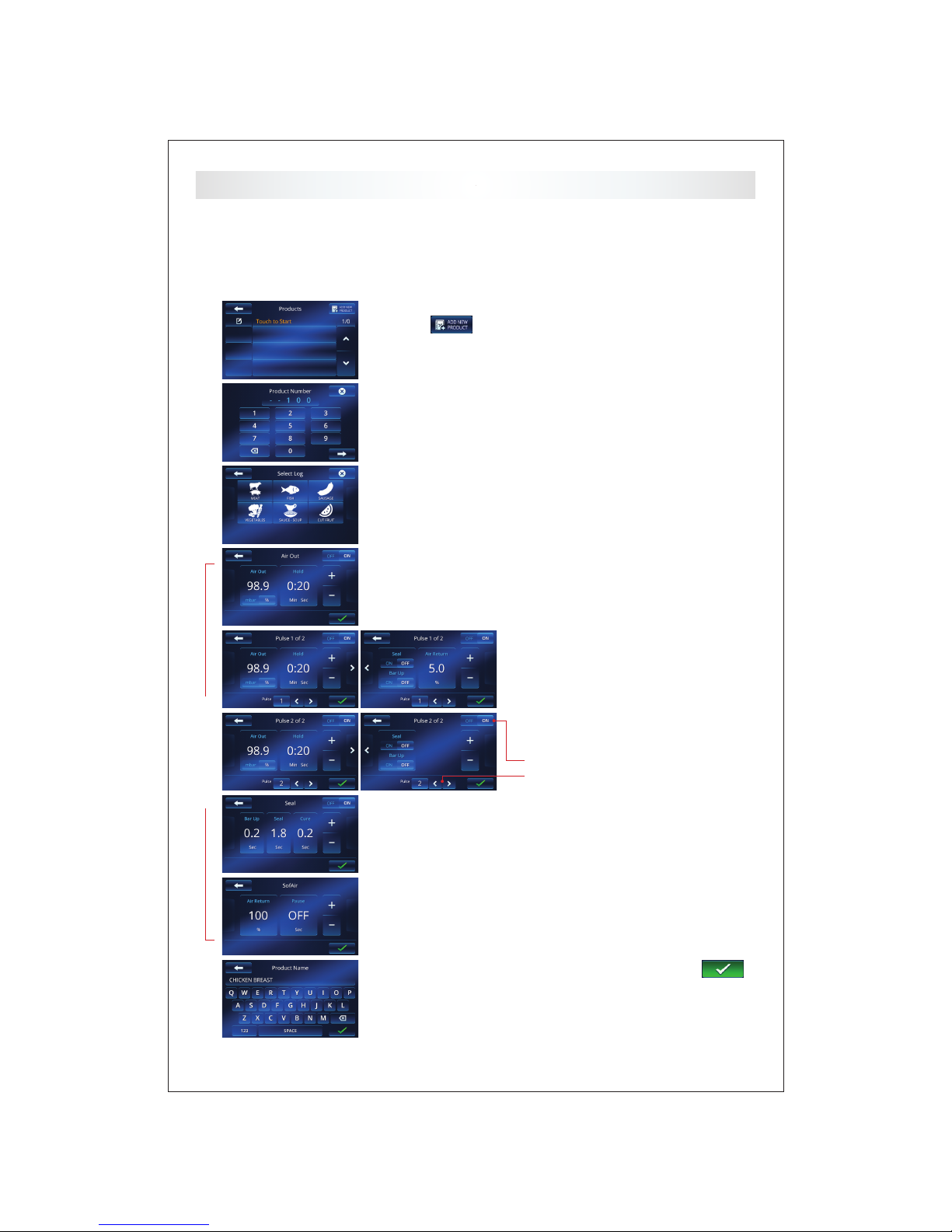

1Presets

Your 400 Series machine comes with 6 most commonly used Presets to get you started. The preset

buttons are listed on the Home screen. Below is a description of their vacuum settings and how they

are being used.

After touching the desired Preset button, place your

food product in the bag, lay the open side over the

sealing bar (see Flippin’ Tray on page 3), close the lid

and touch the green start button to start the vacuuming

process.

Repeat with all products from the same batch. When

you are done, touch the Home button to get

back to the home screen.

- 6 -

VACUUM

Vacuum seal in a bag/pouch for

chilled storage or low temperature

cooking. The preset removes

99.9% of the atmosphere from

the chamber.

SOFT VACUUM

Soft Vacuum seals sausage and

patties in a bag/pouch for chilled

storage or low temperature cook-

ing. The preset removes 97% of

the atmosphere then returning

the air slowly preventing damage.

STEP VACUUM

Step Vacuum seals sh llets, and

hams in a bag/pouch for chilled

storage or low temperature cooking.

The preset removes atmosphere in

increments, preventing boiling

which may harm the product.

INFUSE

Infuse avors in a hotel pan or

Vac-Box to create dramatic avor

& aroma to drinks. The preset

preserves avor, color & fruit

crispness. Enhance the avor

of Spa Water, create Sangria in

minutes.

LIQUID

Liquid seals in a bag/pouch for

chilled storage, retherming or

low temperature cooking. The

preset allows the user to vacuum

seal at temperatures below

150ºF (65ºC).

MARINATE

Marinate in minutes not hours

to create that special avor. The

preset opens and closes the pro-

tein bers allowing liquid marinade

to penetrate. Use a hotel pan or

Vac-Box to instantly marinate.

Note: food safety logging is being skipped for Presets