i

Contents

Contents

1 Safety Information 1-1

1.1 General Safety Information ................................................................................................. 1-1

1.2 Information on Laser Safety ............................................................................................... 1-2

1.2.1 Safety Information .................................................................................................... 1-2

1.2.2 Safety Precautions ................................................................................................... 1-3

1.2.3 Laser Warning Labels .............................................................................................. 1-4

1.3 Information on Electrical Safety ......................................................................................... 1-5

1.3.1 Safety Information .................................................................................................... 1-5

1.3.2 Safety Precautions ................................................................................................... 1-5

2 Introduction 2-1

2.1 Area of Application and System Summary ......................................................................... 2-1

2.2 Signal Flow between the System Components ................................................................... 2-2

2.2.1 Principle ................................................................................................................... 2-2

2.2.2 Decoder ...................................................................................................................2-3

2.3 Different Operating Modes ................................................................................................. 2-3

3 First Steps 3-1

3.1 Unpacking and Inspection .................................................................................................. 3-1

3.2 Operating and Maintenance Requirements ........................................................................ 3-2

3.3 Control Elements, Indicators and Connections ................................................................... 3-4

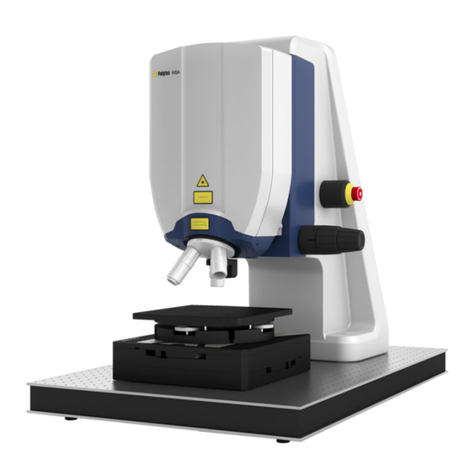

3.3.1 PSV-F-500-HM Front-End ......................................................................................... 3-4

3.3.2 PSV-E-530 Junction Box ........................................................................................... 3-6

3.3.3 PSV-W-500-M PC .................................................................................................... 3-7

3.3.4 PSV-I-500 Scanning Head .......................................................................................3-11

3.4 Assembly ......................................................................................................................... 3-14

3.4.1 Scanning Head ...................................................................................................... 3-15

3.4.2 VIB-A-T02 Light Duty Tripod with Fluid Head ......................................................... 3-16

3.4.3 PSV-A-013 System Cabinet ................................................................................... 3-17

3.5 Cabling ............................................................................................................................ 3-20

3.5.1 Connecting the Hardware........................................................................................ 3-20

3.5.2 Connecting the Signals (M System) ........................................................................ 3-24

3.5.3 Connecting the Signals (H System) ......................................................................... 3-25

3.5.4 Connecting the Mains Cables ................................................................................. 3-26

3.6 Functional Test ................................................................................................................ 3-26

4 Making Measurements 4-1

4.1 Starting the System ............................................................................................................ 4-1

4.2 Selecting Suitable Settings ................................................................................................ 4-2

4.2.1 Measurement Range ................................................................................................ 4-2

4.2.2 Tracking Filter .......................................................................................................... 4-3