i

Contents

Contents

1 Safety Information 1-1

1.1 Information on Using these Operating Instructions ............................................................. 1-1

1.1.1 Warning Notices Used .............................................................................................. 1-1

1.1.2 Notices Used ........................................................................................................... 1-2

1.2 Warning Labels and Mandatory Signs Used on the Equipment .......................................... 1-2

1.3 General Safety Information ................................................................................................ 1-3

1.3.1 Operating the Instrument Safely ............................................................................... 1-3

1.3.2 Intended Use ........................................................................................................... 1-3

1.3.3 User Qualification ..................................................................................................... 1-3

1.3.4 Ambient Conditions .................................................................................................. 1-4

1.3.5 Transport .................................................................................................................1-4

1.3.6 Personal Protective Equipment (PPE) ...................................................................... 1-4

1.3.7 Cleaning ..................................................................................................................1-4

1.3.8 Installing Other Components .................................................................................... 1-5

1.3.9 Disposal ................................................................................................................... 1-5

1.4 Lamp Safety ...................................................................................................................... 1-6

1.4.1 Important Warning Notices ....................................................................................... 1-6

1.4.2 Applicable Standards and Directives ........................................................................ 1-6

1.4.3 Equipment ................................................................................................................ 1-6

1.4.4 Information on Risk Category 0 ................................................................................ 1-6

1.5 Electrical Safety ................................................................................................................. 1-7

1.5.1 Important Warning Notices ....................................................................................... 1-7

1.5.2 Important Notices ..................................................................................................... 1-7

1.5.3 Applicable Standards and Directives ........................................................................ 1-8

2 Introduction 2-1

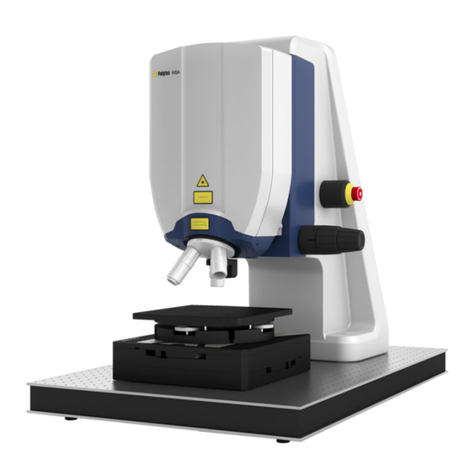

2.1 Area of Application and System Summary ......................................................................... 2-1

2.2 Operating Principle ............................................................................................................ 2-2

3 First Steps 3-1

3.1 Unpacking and Inspection .................................................................................................. 3-1

3.2 Control Elements, Displays, and Connections .................................................................... 3-3

3.2.1 Sensor Head ............................................................................................................ 3-3

3.2.2 Controller ................................................................................................................. 3-6

3.2.3 Data Management System ....................................................................................... 3-8

3.3 Assembly ..........................................................................................................................3-11

3.3.1 Mounting the Sensor Head onto the Stand ............................................................. 3-12

3.3.2 Mounting the Sensor Head without the Stand ......................................................... 3-14

3.3.3 Mounting Spacer Ring and Tip-Tilt Unit .................................................................. 3-15

3.3.4 Mounting the Test Sample onto the Tip-Tilt Unit ..................................................... 3-15