ii

Contents

3 First Steps 3-1

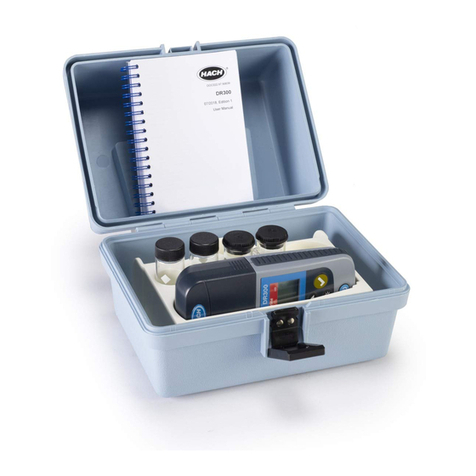

3.1 Unpacking and Inspection ...................................................................................................3-1

3.2 Control Elements, Displays, and Connections .....................................................................3-4

3.2.1 Sensor Head .............................................................................................................3-4

3.2.2 Front-End .................................................................................................................3-5

3.2.3 Controller ..................................................................................................................3-7

3.2.4 Data Management System .......................................................................................3-8

3.3 Assembly ..........................................................................................................................3-12

3.3.1 Sensor Head ...........................................................................................................3-12

3.3.2 Objective Adapter/Objective Turret ..........................................................................3-13

3.3.3 Objective Positioner (with MSA-A-TMS Option) .......................................................3-14

3.3.4 Holder for Objective Positioner (with MSA-A-TMS Option) ......................................3-16

3.4 Cabling .............................................................................................................................3-19

3.4.1 Connecting the Protective Earth Cable ...................................................................3-21

3.4.2 Connecting the Hardware .......................................................................................3-25

3.4.3 Connecting the Signals ...........................................................................................3-31

3.4.4 Connecting the Mains Cables .................................................................................3-33

3.5 Functional Test .................................................................................................................3-33

3.5.1 Out-of-Plane Vibrations ...........................................................................................3-33

3.5.2 In-Plane Vibrations .................................................................................................3-38

3.5.3 Topography Measurement .......................................................................................3-44

4 Operating 4-1

4.1 Software .............................................................................................................................4-1

4.2 Selecting and Exchanging Objectives .................................................................................4-1

4.3 Overview of the Parfocal Lengths of the Objectives ............................................................4-2

5 Troubleshooting 5-1

5.1 General Tests .....................................................................................................................5-1

5.2 Problems Connecting to the Signal Generator ....................................................................5-3

5.3 Problems Connecting to the Front-End ...............................................................................5-3

5.4 No Laser Beam ...................................................................................................................5-4

5.5 Illumination Module in the Sensor Head does not Light up ..................................................5-4

5.6 Laser Beam is Not Pointing at the Scan Points ...................................................................5-4

5.7 Measurement Signal is Faulty .............................................................................................5-5

5.8 Measurement Takes an Unusually Long Time .....................................................................5-5

6 Technical Specifications 6-1

6.1 Harmonized Standards Applied ...........................................................................................6-1

6.2 MSA-I-620 Sensor Head .....................................................................................................6-1

6.2.1 General Data ............................................................................................................6-1

6.2.2 Optics .......................................................................................................................6-5

6.3 MSA-F-620 Front-End .........................................................................................................6-6

6.3.1 General Data ............................................................................................................6-6

6.3.2 Signal Inputs and Outputs .........................................................................................6-7

6.4 MSA-E-600 Controller .........................................................................................................6-8