C–GeneralInformation

C‐

4

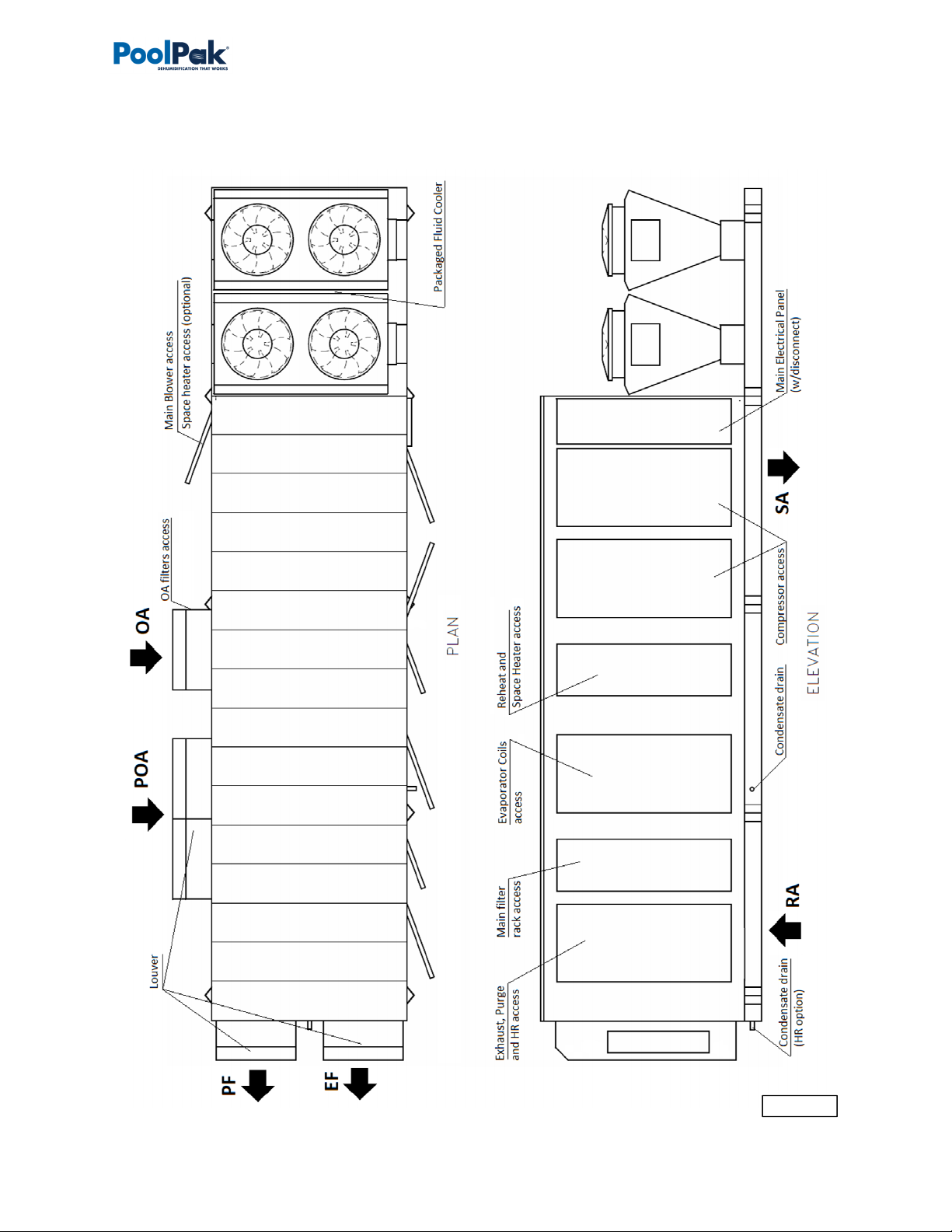

Standardlargedehumidifiersaresemi‐custom:whilebasicconceptandlayoutisthesame,optionsandspecific

systemsandcomponentslayoutandlocationmayvaryfromonedehumidifiertoanother.Oneofthetypical

dehumidifierarrangementisshownonPic.C.1.

DehumidifierOptions

Indoororoutdoorinstallation.

o Note:Pic.C.1.showsoutdoormodel,equippedwithlouvers(toprotectairintakeanddischarge

openingsfromelements).Indoormodelwouldhaveductsconnectedtorespectiveopenings,no

louverswouldbeneeded.

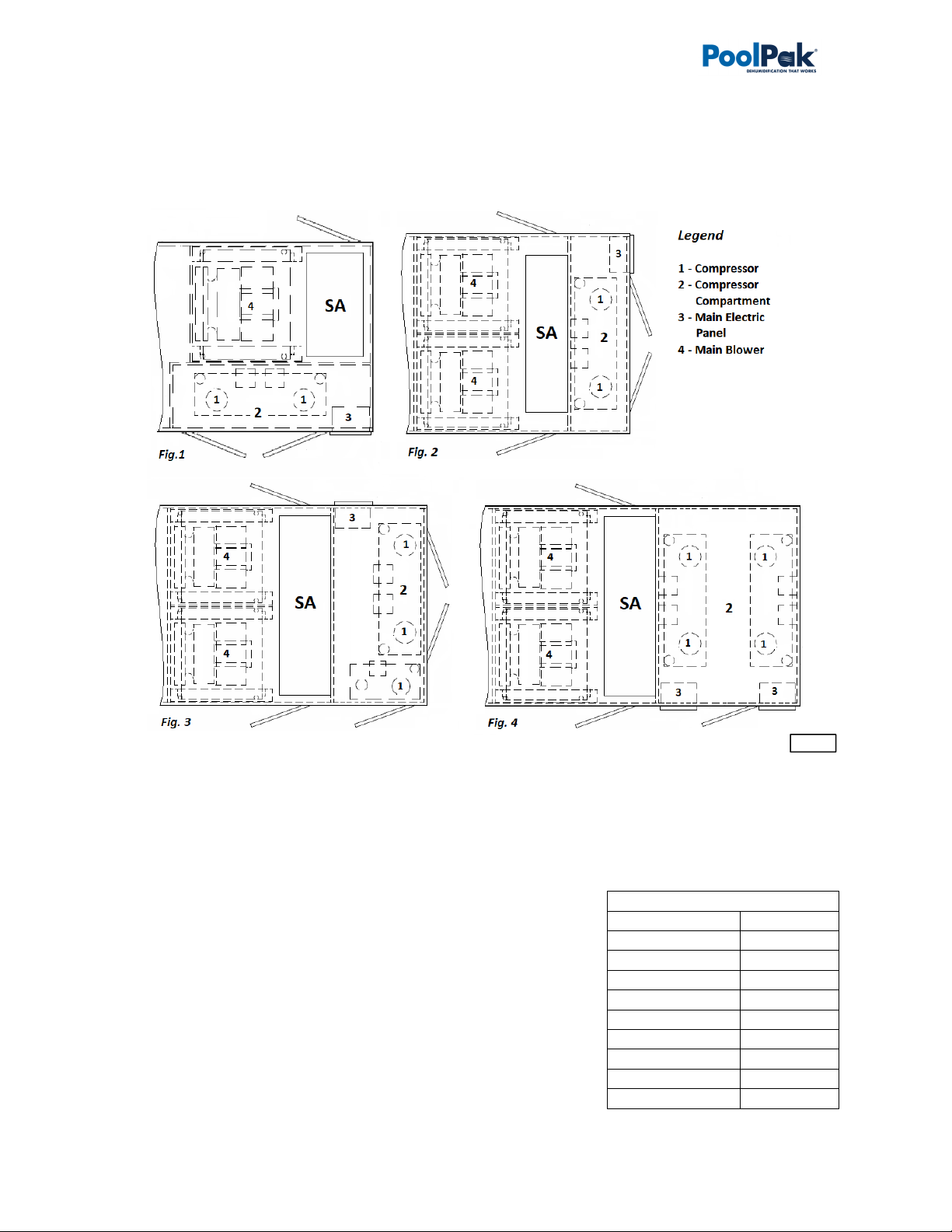

Capacity(numberofcompressors)–twotofourcompressors(seeDehumidifierOptionalArrangementbelow

formoredetails):

o Two‐compressordehumidifieroption(modelsPPK070toPPK340).

o Three‐compressordehumidifieroption(modelsPPK380andPPK420).

o Four‐compressordehumidifieroption(modelPPK530).

Airflow/ductworkconnection*.Pic.C.1showssomeoptionsonly;eachoptionlocationavailabilitydependson

thedehumidifierinstallation(indoororoutdoor)andotheroptions:

o ReturnAir(RA)ductworkconnection‐top,bottom,end,sides.

o SupplyAir(SA)ductworkconnection–top,bottom,sides.

o OptionalMinOutdoorAir(OA)ductworkconnection/termination–top,sides.

o OptionalMinExhaustFan(EF)andPurgeFan(PF)ductworkconnections/terminations–end,sides.

o OptionalPurgeOutdoorAir(POA)ductworkconnection/termination‐top,sides.

OptionalPoolWaterHeating**.

o Dehumidifiercanaccommodateuptotwopoolwaterheatingcircuits

OptionalSpaceHeating‐hotwatercoil,electricorgasheater***.

OptionalHeatRecovery(HR)circuit.

AirConditioning(AC)*–externalwatercoolingorfluidcooler(packagedorseparate).

o Note:Pic.C.1showsoutdoormodelwith“packaged”fluidcooler(mountedwiththedehumidifier).

“Packaged’ACoptionisavailableforoutdoormodelsonly;alternatively,indoorandoutdoormodels

couldbefittedforseparate/remoteACoption–remotefluidcoolerorotherexternalcoolingmedia

source.

*

Someavailableoptions(tonnage,ductworkconnections,ACoptionsetc.)areshown.Refertothesubmittal

andotherrelevantdocumentationforyourdehumidifier’soptions.

** Thepoolwaterheatingoptionreliesoncompressor‐createdexcessheatandisusedasanadditional

heatingsource.Itdoesnoteliminatetheneedforamainpoolwaterheater.

*** Forspecificdetailsonspaceheating(hotwater,gas,electric)option,refertothesubmittalandother

documentation:

Gas‐firedductheatercanbeinstalledinternally(fittedinsidethedehumidifieratthefactory)orprovidedforfield

installation(tobefittedinthesupplyairductwork).

Electricheaterorhotwatercoil,dependingoncapacity,model,size,etc.,canbeinstalledexternally(mountedonthe

topofSAopeningorfittedinthesupplyairductwork)orinternally.Refertoyourdehumidifier’ssubmittal

documentation.

Attention!EquipmentClearancesandDimensions!

CAUTION!

Forequipmentproperoperation,maintenanceandservice,respectiveclearancesshouldbe

maintained.Generally,30”clearancestotheequipmentmustbekeptforthemaintenanceandservicepurposes.

Forthespecificrequiredclearancesinformation,aswellasdehumidifieroveralldimensions,distancestopipe

connections,ductconnectionsetc.,refertothesubmittaldocumentation.