TABLE OF CONTENTS

General Information ................................................................................................................... 4

Operating Safety (Warnings, Cautions, and Notes) ........................................................................................4

Reference and Additional Information............................................................................................................5

Contact Us .................................................................................................................................................5

Basic Information .......................................................................................................................................6

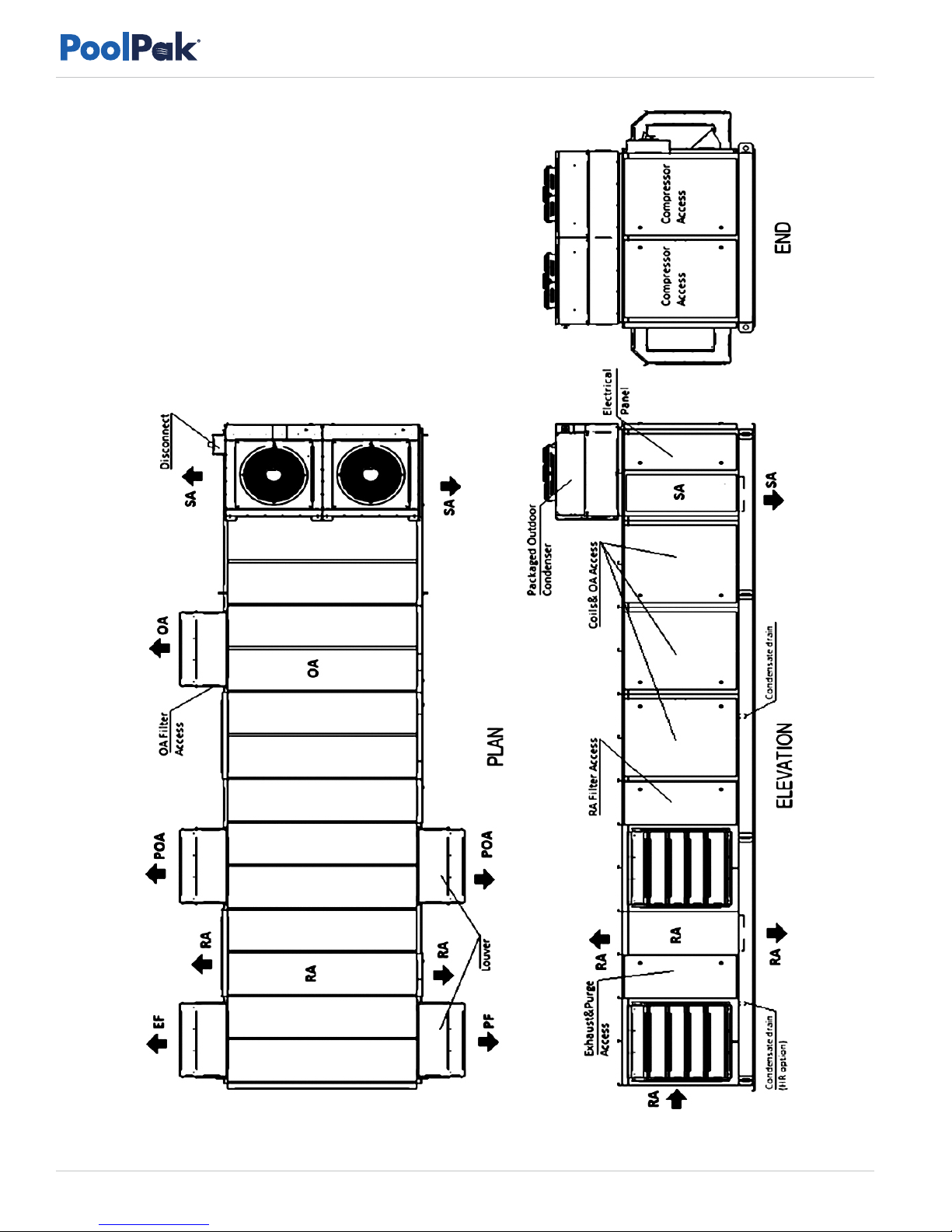

Dehumidifier View and Options ....................................................................................................................6

Dehumidifier Options ..................................................................................................................................7

Dehumidifier External Systems Connection .....................................................................................................8

Dehumidifier Optional Arrangement. .............................................................................................................9

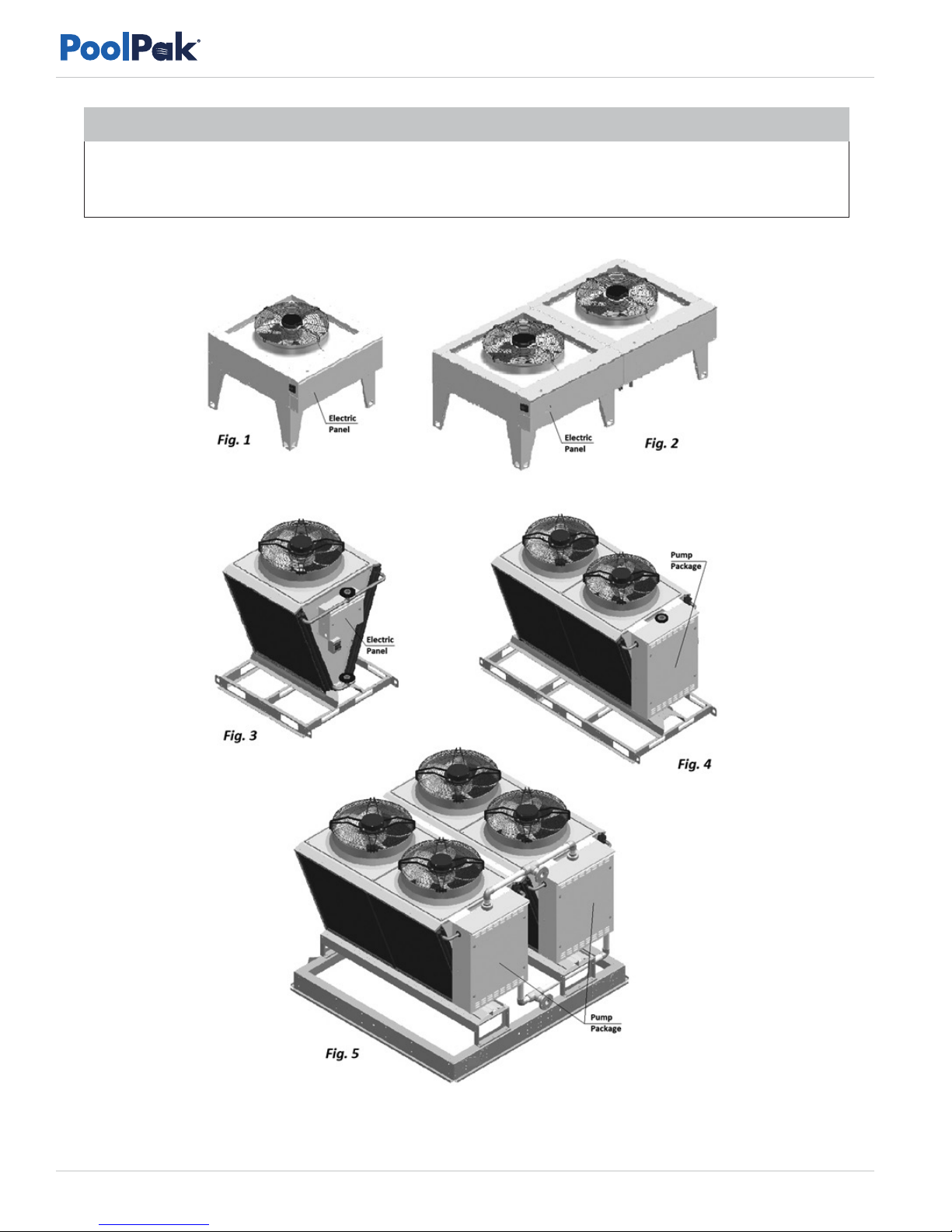

Air Conditioning Options – Outdoor Air Condensers (OACC) and Fluid Coolers (OAFC).....................................9

Equipment Specific Data ........................................................................................................................... 11

Layout and Components ........................................................................................................... 13

Dehumidifier Main Components ................................................................................................................. 13

Control System..........................................................................................................................................15

Outdoor Air Condensers and Fluid Coolers Layout and Components............................................................... 17

Fluid Coolers Pump Package....................................................................................................................... 18

Sequence of Operation ............................................................................................................. 19

Set Points .................................................................................................................................................19

Ventilation. ...............................................................................................................................................19

Purge (Additional Exhaust) Option...............................................................................................................19

Heat Recovery Option. ..............................................................................................................................20

Air Conditioning, Dehumidification and Pool Heating. ...................................................................................20

Economiser Mode Option. ........................................................................................................................20

Compressor(s)...........................................................................................................................................21

Compressor Circuit Operation ....................................................................................................................21

Outdoor Air Condenser and Fluid Cooler Operation.....................................................................................22

Space Heating..........................................................................................................................................22

Interface and Communication ................................................................................................... 23

Touch Display Operator Panel ...................................................................................................................23

Alarms.....................................................................................................................................................24

Remote Communication (Virtual-Tech and BMS) ............................................................................................25

Virtual-Tech...............................................................................................................................................25

BMS (Building Management System) ...........................................................................................................26

Basic Maintenance .................................................................................................................... 27

Maintenance and Safety............................................................................................................................27

Maintenance Key Points .............................................................................................................................27

Routine Maintenance Program ....................................................................................................................28

Specific Components Maintenance .............................................................................................................29

ASHRAE

62.1-2 013

3491 Industrial Drive

York, Pennsylvania 17402 USA

717-757-2648 • Fax 717-757-5085 • www.PoolPak.com

© 2018 PoolPak LLC. All rights reserved. SVW11-PCPOMMBX-20180828