EN

3

± 0°

ALWAYS WEAR SAFETY GLASSES WITH DEFLECTORS WHEN

USING THE MACHINE.

ALWAYS WEAR GLOVES WHEN USING THE MACHINE.

ALWAYS WEAR HEARING PROTECTION WHEN USING THE

MACHINE.

ALWAYS WEAR STEEL TOE-CAPPED SHOES WHEN USING

THE MACHINE.

DO NOT BACK UP THE MACHINE UNLESS ABSOLUTELY

NECESSARY. ALWAYS CHECK THE GROUND AND BEHIND

YOU BEFORE MOVING.

CLEAR THE WORK ZONE OF OBJECTS SUCH AS SMALL

STONES, TOYS, METAL WIRES, STICKS, ETC. THEY CAN BE

CUT AND/OR LIFTED AND PROJECTED BY THE BLADE.

NEVER USE THE MACHINE IF THE PROTECTION GUARDS

AND OTHER SAFETY DEVICES ARE NOT IN PLACE.

STOP THE ENGINE WHEN CROSSING DRIVEWAYS,

SIDEWALKS OR STREETS.

DO NOT USE THE MACHINE IF YOU ARE UNDER THE

INFLUENCE OF ALCOHOL OR DRUGS.

NEVER USE THE MACHINE ON WET GRASS. WALK AT A

STEADY PACE, HOLD ON TO THE HANDLE AND WALK

NEVER RUN.

IF THE MACHINE STARTS TO VIBRATE ABNORMALLY, STOP

THE ENGINE AND CHECK IMMEDIATELY FOR THE CAUSE.

STRONG VIBRATIONS ARE USUALLY A SIGN SOMETHING IS WRONG

STOP THE ENGINE BEFORE CLEANING, INSPECTION OR

REPAIRS.

BOLTS AND NUTS, ESPECIALLY THE BOLTS USED TO ATTACH

THE BLADE SHOULD ALWAYS BE PROPERLY TIGHTENED.

KEEP THE MACHINE IN GOOD CONDITION.

NEVER TAMPER WITH SAFETY DEVICES. REGULARLY CHECK

THEY ARE WORKING PROPERLY.

KEEP GRASS, LEAVES OR DEBRIS OF ANY KIND FROM

ACCUMULATING ON THE MACHINE OR IN FRONT OF THE

BLADE. CLEAN OIL OR FUEL SPILLAGES.

ALLOW THE MACHINE TO COOL BEFORE STORING IT.

IF YOU HIT AN OBJECT, STOP THE MACHINE AND CHECK

FOR DAMAGE. BEFORE RESTARTING, REPAIR THE DAMAGE

IF NECESSARY.

THE MACHINE'S BLADE CAN CUT. WRAP THE BLADE OR

WEAR GLOVES AND BE CAREFUL WHEN PERFORMING

MAINTENANCE ON THE BLADE.

2. Checks before use

2.1 When receiving

Inspect the box to detect any obvious damage. If a part is missing or

damaged, notify the carrier immediately. Please refer to the

assembly manual for the contents of your machine.

2.2 Assembly and start-up

2.2.1 Assembly

The Perimeter Wire Machine 600MHTM was completely assembled

at the factory except for the following parts:

blade, wire guide, sliding foot, blade pulley

cover, wheels and handle. To ensure safe and

appropriate operation, these parts must be

attached securely. Use the appropriate

wrench to ensure they are tightened sufficiently.

To assemble the components mentioned

above, please follow the instructions in the

600MH ASSEMBLY MANUAL.

IT IS ESSENTIAL THAT ALL OF

THE STEPS ARE CARRIED

OUT

2.2.2 Start-up – Preparation and start-up of the engine

Perimeter wire machine 600MHTM is equipped with a four-stroke

GXH-50cc Honda engine.

2.2.2.1 Engine Oil

2.2.2.2 Gasoline(petrol)

IMPORTANT: Fill the tank with the machine resting on the

support foot to avoid overfilling.

Fill the tank with UNLEADED gasoline. Do not use an oil/gasoline

mixture. This machine is equipped with a four-stroke engine. Consult

the Honda engine manual for more information.

2.2.2.3 First use

Consult the Honda

engine manual for

starting instructions.

The on/off switch is

located on the

engine.

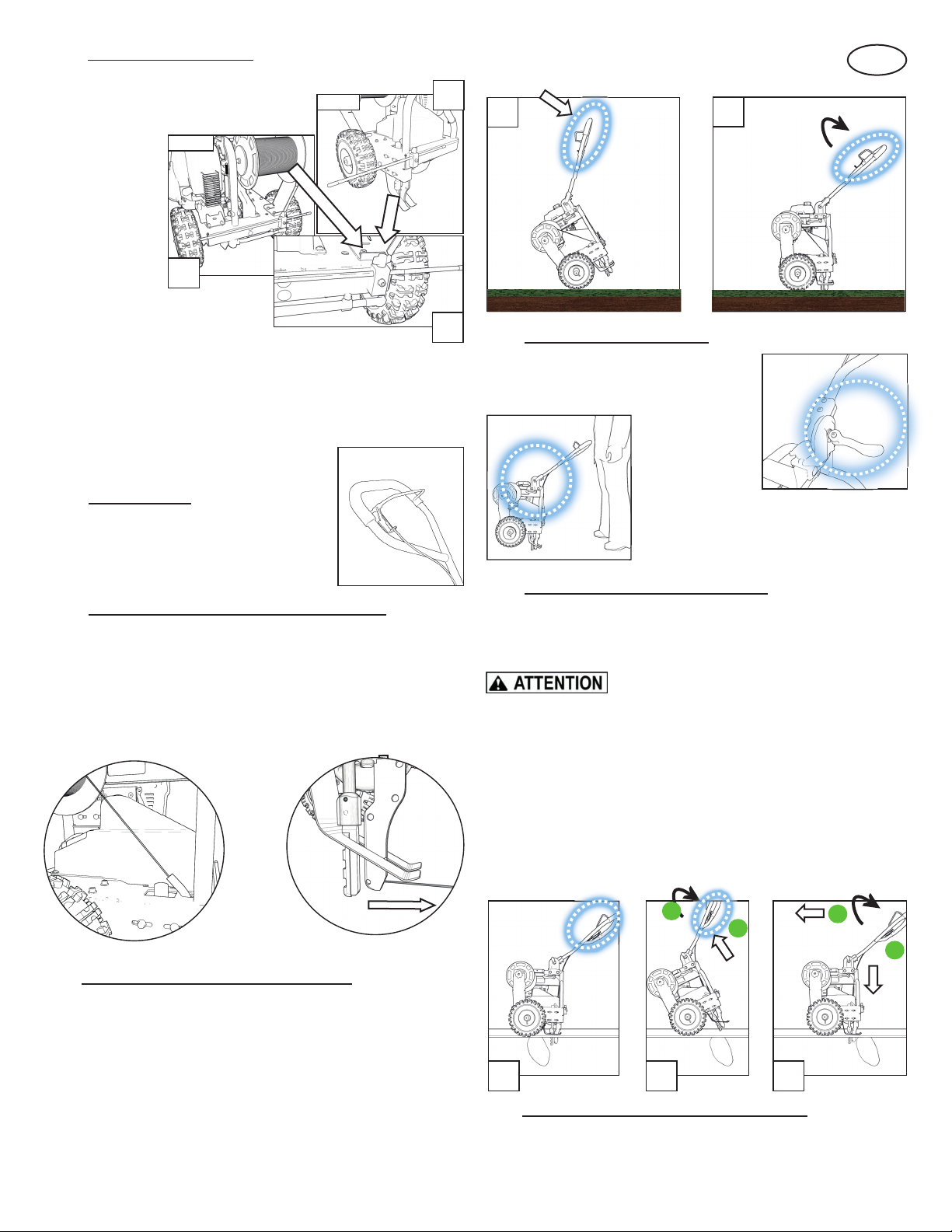

Take care to pull the

starter grip in the

output axis of the

rope. If it is pulled

vertically, the friction of the rope on the plastic housing may damage

the rope and/or the housing (see Figures).

IMPORTANT: Let the engine idle for five (5) minutes.

2.2.3 Oil level warning system (Oil AlertTM)

The Honda engine GXH-50 is equipped with the Oil AlertTM system

that automatically cuts the ignition when the oil level in the crankcase

falls below a safe level. The Oil AlertTM system also stops the engine

when the engine’s operating angle exceeds 20 degrees (± 4 degrees).

Check the oil level before each use. Add oil if necessary.

Fill the Honda engine with a maximum

of 0.25 liters of SAE 10W-30 API SJ oil.

For special uses and in extreme

temperature conditions, consult the

Honda engine manual.

Follow these instructions to make sure

that the engine receives the correct

quantity of oil.

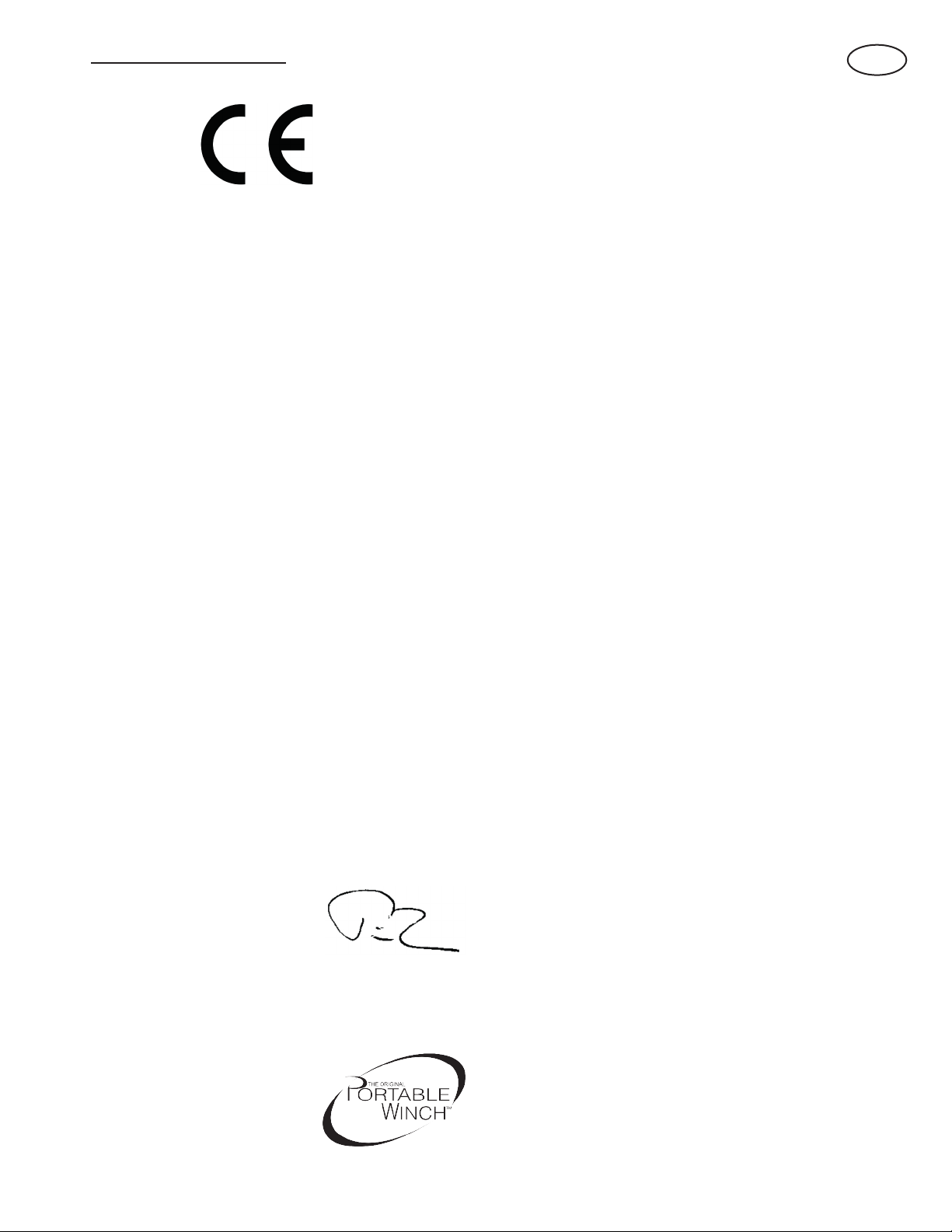

1. Position the machine so that the

engine is level (Figure 1);

2. Fill the crankcase (Figure 2);

3. Check the oil level. It should be up

to the edge of the opening when

the engine is level (Figure 2).

1

2

3