2

10

1

2

3

4

5

6

7A

7B

8

9

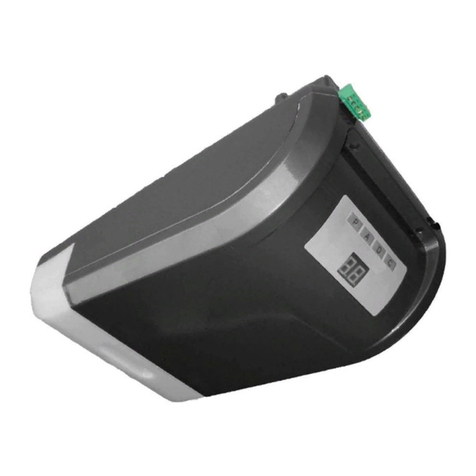

The TOP500 operator is a product for residential

use, adaptable to all types of sliding gates.

To ensure full operation of the operator, check that

the door frame is strong enough.

The gate should be level.

Check that the gate has a uniform movement,

with no irregular friction during the entire stroke.

Check that the dimensions and weight of the gate

match those shown in the technical data of the

engine.

1 • Motor TOP500 (1x)

2 • Release keys (2x)

3 • Screws M5x10 (4x)

4 • Fixing screws to the plate (4x)

5 • Fixing screws to the ground (4x)

6 • Fixation plate (1x)

7A • Fixation plate of the limit switches magnetic (2x)

7B • Fixation plate of the limit switches mechanical (2x)

8 • Photocells (2x)

9 • Remote controls (2x)

10 • Contral board MC1 (1x)

11 • User’s manual (1x)

SAFETY INSTRUCTIONS

CONTENT

PRE-INSTALLATION..................................................................................

PACKAGE................................................................................................

OPERATOR.............................................................................................

INSTALATION...........................................................................................

CREATE FOUNDATION.......................................................................

EXISTING FOUNDATION....................................................................

APPLICATION OF MOTOR.................................................................

UNLOCK OPERATOR.........................................................................

INSTALLATION OF NYLON GEAR RACK...........................................

INSTALLATION OF STEEL GEAR RACK............................................

INSTALLATION OF PLATES THE LIMIT SWITCHES..........................

COMPONENTS TEST.............................................................................

MAINTENANCE......................................................................................

CHECK DISTANCES AND TIPS..........................................................

CHECK FRICTION BETWEEN RACK AND PINION...........................

LUBRICATING COMPONENTS...........................................................

TROUBLESHOOTING.............................................................................

2

2

3

4

4

4

5

5

6

6

6

7

7

8

8

8

9

PRE-INSTALLATION

PACKAGE

ou

• It is important for your safety that these instructions

are followed.

• Keep these instructions in a safe place for future re-

ference.

• The Supplier is not responsible for the improper use

of the product, or other use than that for which it was

designed.

cal wires, essentially on the power cable.

• When programming the control unit, pay particular

attention to touching only the location intended for that

purpose. Failure to do so may result in electric shock.

• The Supplier is not responsible if safety standards

were not taken into account when installing the equip-

ment, or for any deformation that may occur.

• The Supplier is not responsible for insecurity and mal-

function of the product when used with components

that were not sold by the them.

• This product was designed and manufactured strictly

for the use indicated in this manual.

• Any other use not expressly indicated may damage

the product and/or can cause physical and property

damages, and will void the warranty.

• Do not make any changes to the automation compo-

nents and/or their accessories.

• Keep remote controls away from children, to prevent

the automated system from being activated involunta-

rily.

• The customer shall not, under any circumstances, at-

tempt to repair or tune the operator. Must call qualified

technician only.

• The installer must have certified professional knowle-

dge at the level of mechanical assemblies in doors and

gates and control board programmation. He should

also be able to perform electrical connections in com-

pliance with all applicable regulations.

• The installer should inform the customer how to han-

dle the product in an emergency and provide him the

manual.

• This device can be used by children 8 year old or older

and persons whose physical, sensory or mental capa-

cities are reduced, or by persons without experience

or knowledge if they have received supervision or ins-

tructions on the use of the device in a safe manner and

understood the hazards involved. Children should not

play with the device. Cleaning and maintenance by the

user must not be carried out by unsupervised children.

• Before installing, the installer must verify that the tem-

perature range indicated on the operator is appropriate

to the location of the installation.

• Before installing, the installer must verify that the

equipment to be automated is in good mechanical

condition, correctly balanced and opens and closes

properly.

• If the operator is to be installed at a level higher than

2,5 m above ground level or other level of access, ,

should be followed the minimum safety and health re-

quirements for the use of work equipment workers at

work in Directive 2009/104/EC of the European Parlia-

ment and of the Council of 16th September of 2009.

• In the case of the equipment where the automation

will be installed, have a pedestrian door, be aware that

it must be closed when the operator is activated.

• After installation, make sure that the mechanism is

properly adjusted and that the protection system and

any manual unlocker works correctly.

• In order to protect the electrical cables against me-

chanical stress, you should use conduit for the electri-

This product is certified in accordance with

European Community (EC) safety stan-

dards.

This product complies with Directive

2011/65/EU of the European Parliament

and of the Council, of 8 June 2011, on the

restriction of the use of certain hazardous

substances in electrical and electronic

equipment.

(Applicable in countries with recycling

systems). This marking on the product or

literature indicates that the product and

electronic accessories (eg. charger, USB

cable, electronic material, controls, etc.)

should not be disposed of as other hou-

sehold waste at the end of its useful life.

To avoid possible harm to the environ-

ment or human health resulting from the

uncontrolled disposal of waste, separate

these items from other types of waste and

recycle them responsibly to promote the

sustainable reuse of material resources.

Home users should contact the dealer

where they pruchased this product or the

National Environment Agency for details

on where and how they can take these

items for environmentally safe recycling.

Business users should contact their ven-

dor and check the terms and conditions of

the purchase agreement.

This product and its electronic accessories

should not be mixed with other commercial

waste.

This marking indicates that the procut

and electronic accessories (eg. charger,

USB cable, electronic material, controls,

etc.) are susceptible to electric shock by

direct or indirect contact with electricity.

Be cautious when handling the product

and observe all safety procedures in this

manual.