4

BEFORE USE

1. Before using this product, read the owner's manual

completely and familiarize yourself thoroughly with

the product, its components and recognize the

hazards associated with its use.

2. Inspect before each use. Do not use if bent, broken,

leaking or damaged components are noted.

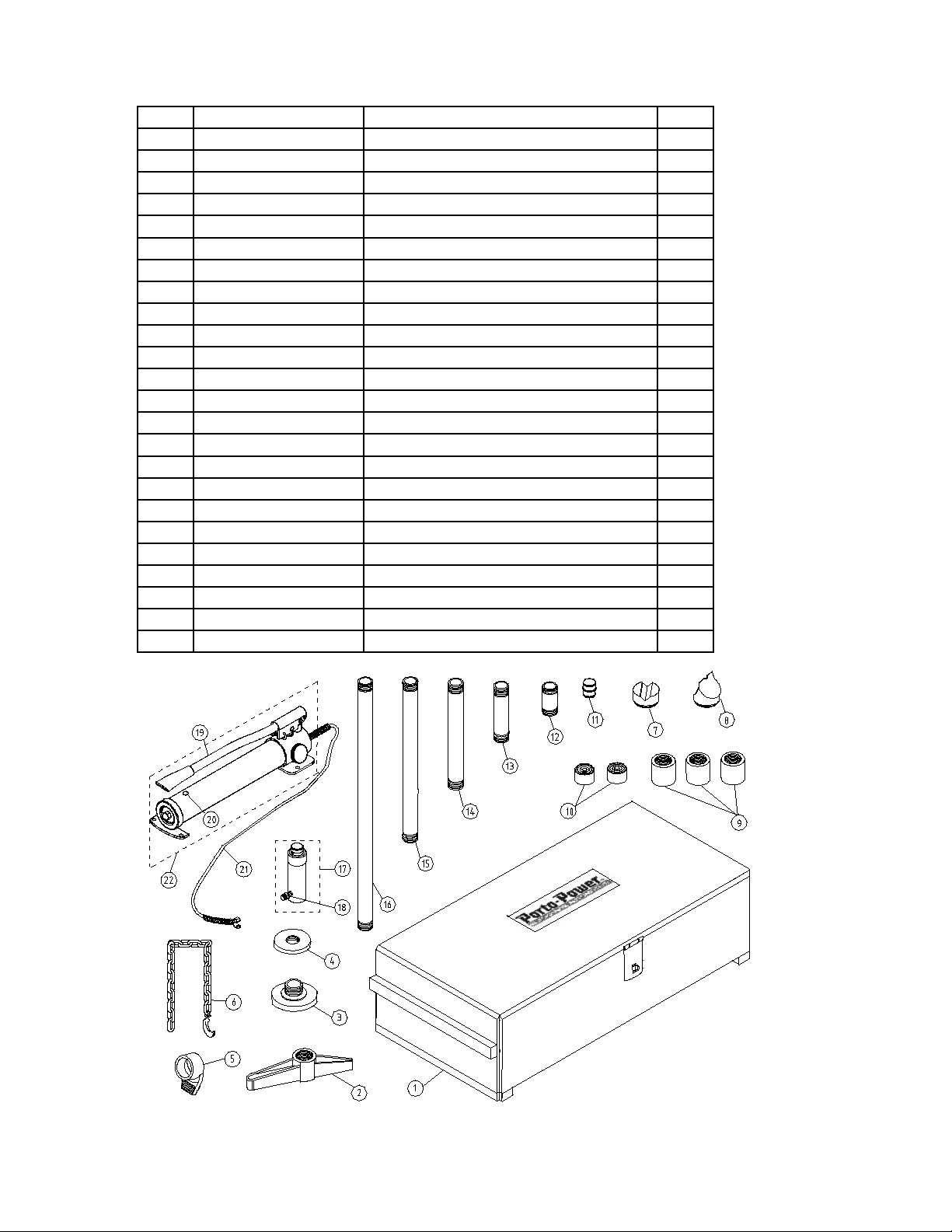

3. Check to ensure that all parts of your kit are included

(see illustration and parts list).

4. Carefully remove the dust caps and plugs from hose

coupler and ram coupler.

5. Connect hose coupler to ram coupler, ensure that

there are no fluid leaks.

6. Locate and open release valve. Close release

valve clockwise and pump handle until ram is fully

extended, then open release valve counter-clockwise

until ram has fully retracted.

7. With ram fully retracted and release valve open, place

pump in horizontal position. Open oil filler screw (on

reservoir body, near the back). This will release air

trapped within the reservoir. Re-tighten the oil filler

screw.

8. If using with air actuated units, an air source of at

least 7.8 CFM @ 110 psi is required.

GENERAL SAFETY INFORMATION

1. Ensure that attachments are fully engaged before

applying load.

2. Ensure that load is centrally applied to attachment or

ram saddle. Do not load off center.

3.

Always monitor the force applied to workpiece by

using a load cell and indicator or you may monitor

pressure developed in the ram by using an inline

pressure gauge, then calculate the applied force

using the formula:

F = P x A, where F = lb force, P = pressure in psi,

and A = effective ram area in in2 = 5.14 in2

Refer to Load-Pressure correlation chart on page 9.

If bowing or bending of ram or any attachment occurs

during use, "STOP", release pressure immediately

and reconsider application. Application may not

be compatible with product, a ram kit with a higher

capacity may be needed.

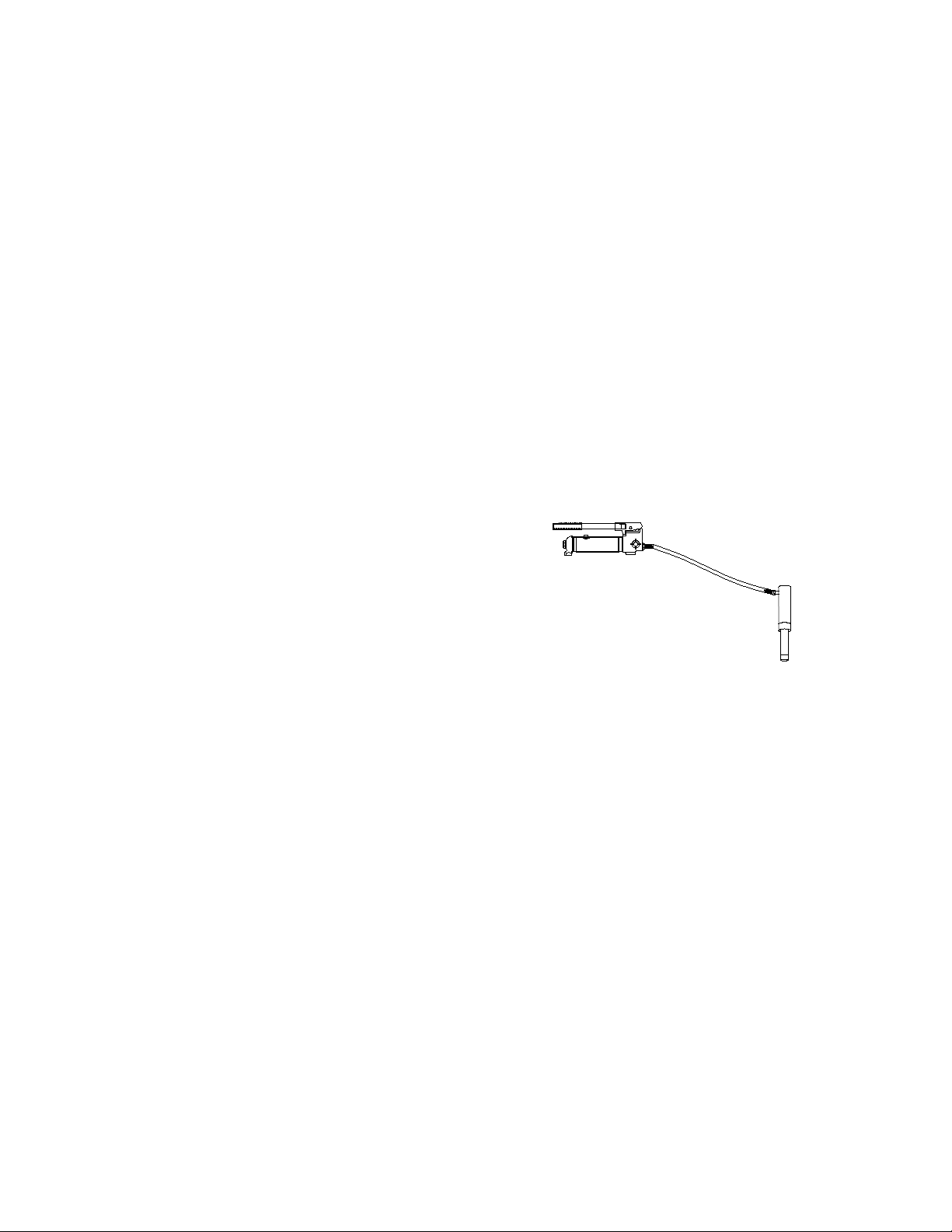

Figure 2 - Horizontal and Vertical position

OPERATION

ALWAYS monitor pressure, load or position

using suitable equipment. Pressure may be

monitored by means of an optional manifold and

gauge. Load may be monitored by means of a load

cell and digital indicator.

Note: Any attachment that is not loaded centrally,

as through the centerline of the ram, is considered

to be “offset”.

When extension tubes and/or offset

attachments are used, the rated capacity is always

reduced by 50% for each tube or offset attachment

connected.

1. Pump may be used in horizontal and vertical position

as illustrated on figure 2 below.

2. Locate and close release valve by turning it clockwise

until firmly closed. (Do not over tighten)

3. Operate by pumping handle. This will send fluid

from the pump reservoir into the high pressure hose

assembly and into the ram assembly.

4. Continue pumping until ram reaches desired

position.

NEVER operate pump with release valve

closed and disconnected from application. If

operated in this condition, the hose and connections

become pressurized. This increases burst hazard.

Damage may occur to pump and its components.

5. To Release Pressure on work piece: Slowly, carefully

turn the release valve counter-clockwise until ram

retracts to desired position. Never turn release

valve more than 1/2 full turn. The ram return system

is spring loaded and the release valve system is

metered, allowing controlled retraction of the ram.

!

!