6

Issue5–January2014

Caution Notes

It is important that the MiniVap is installed and operated in such a way that all applicable Health and

Safety requirements are met. It is the user’s responsibility to ensure that all relevant Health and Safety

Regulations are identified and complied with. Failure to do so may result in damage to the equipment

and could cause personal injury. In particular, the user should study the contents of this guide carefully

before handling or operating this equipment.

Under No circumstances will the supplier of this equipment be liable for any incidental, consequential or

any special damages of any kind whatsoever, including but not limited to lost profits arising from, or in

any way connected with the use of this equipment or this instruction manual.

Warranty is invalidated if the unit is opened or tampered with, in any way, without

prior authorisation of Porvair Sciences or the manufacturer.

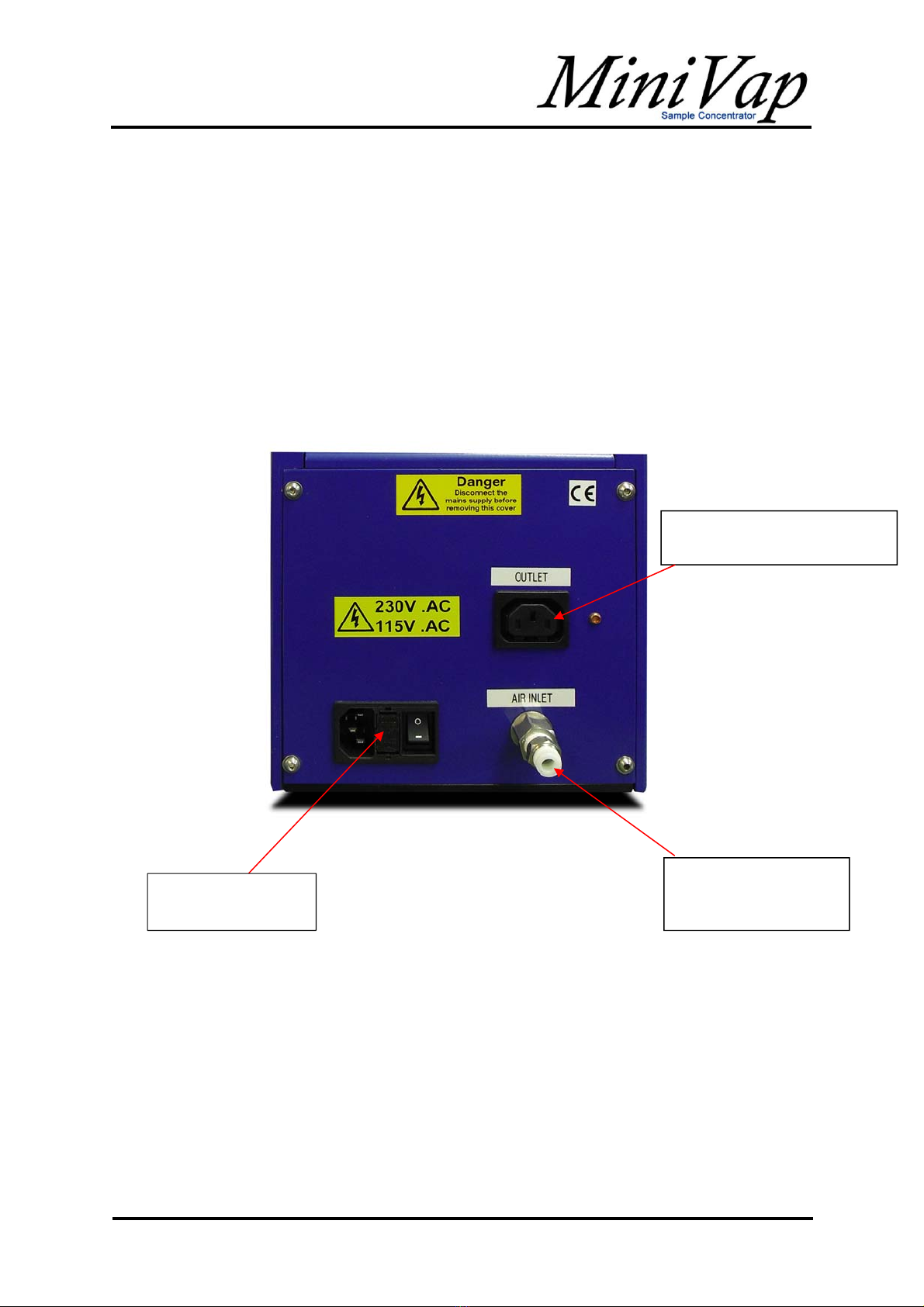

Warning: The MiniVap operates on Dual Voltage mains supply,

either 115V or 230V 50Hz or 60Hz

Warning: Only approved, supplied mains cord set must be used with this instrument.

Refer to System Requirements section for more information.

Warning: If it is required to use an extension lead, the lead must be earthed.

Operational controls

•The height of the platform must be controlled to prevent damage to needles or

microplate

Special requirements

•The instrument is designed to operate at a maximum temperature of 60ºC. Certain

components will become HOT during normal operation of this equipment. Please be

aware of all warning signs relating to hot surfaces

•The instrument must be used in a well-ventilated area. Use of fume extractor or use

in a fume cupboard is recommended.