7

Technical Support: +44(0)23 9269 6638 (option 3) PAK200582_02B August 2016 ©2016 ELMDENE INTERNATIONAL LTD

Standby Battery

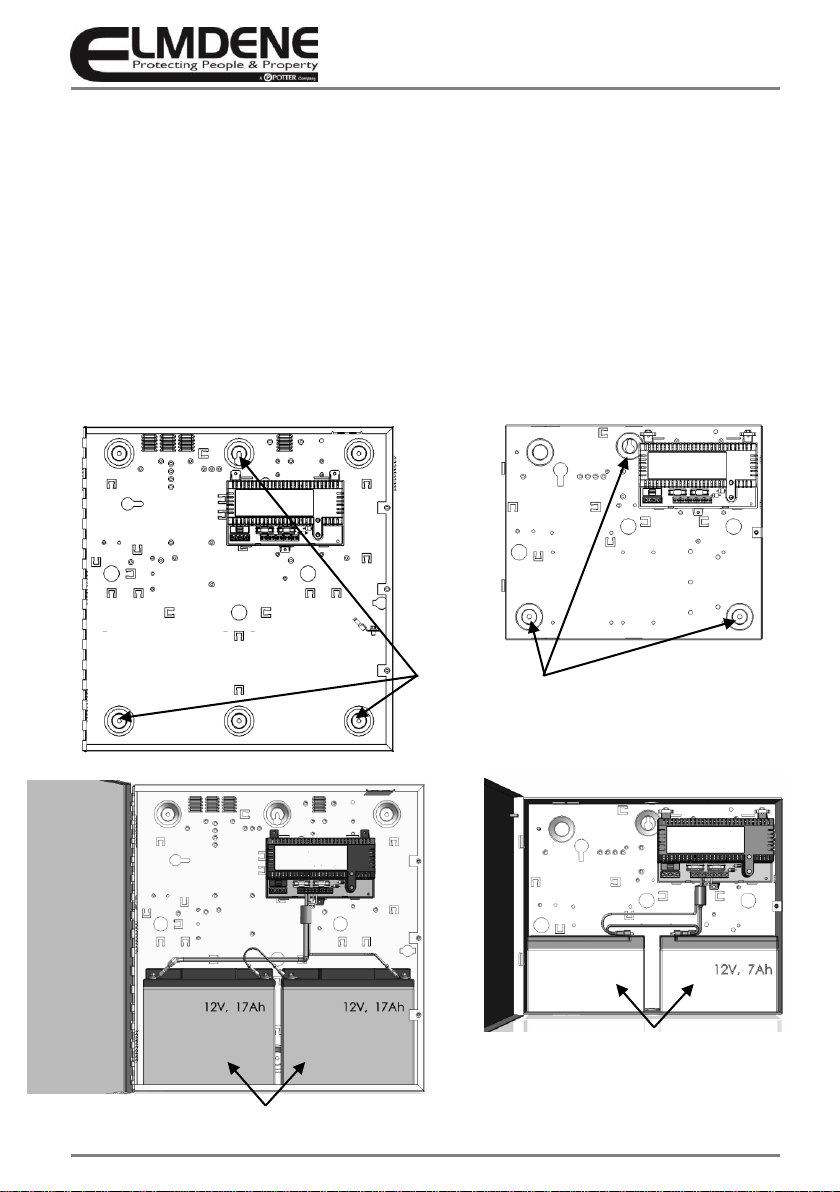

10) Mount the appropriate batteries as shown in Figure 2. Where a dual box solution is used all cabling

between the two boxes should be routed to use separate case entry/exit holes from other cabling and use

suitable bushes to protect the cables.

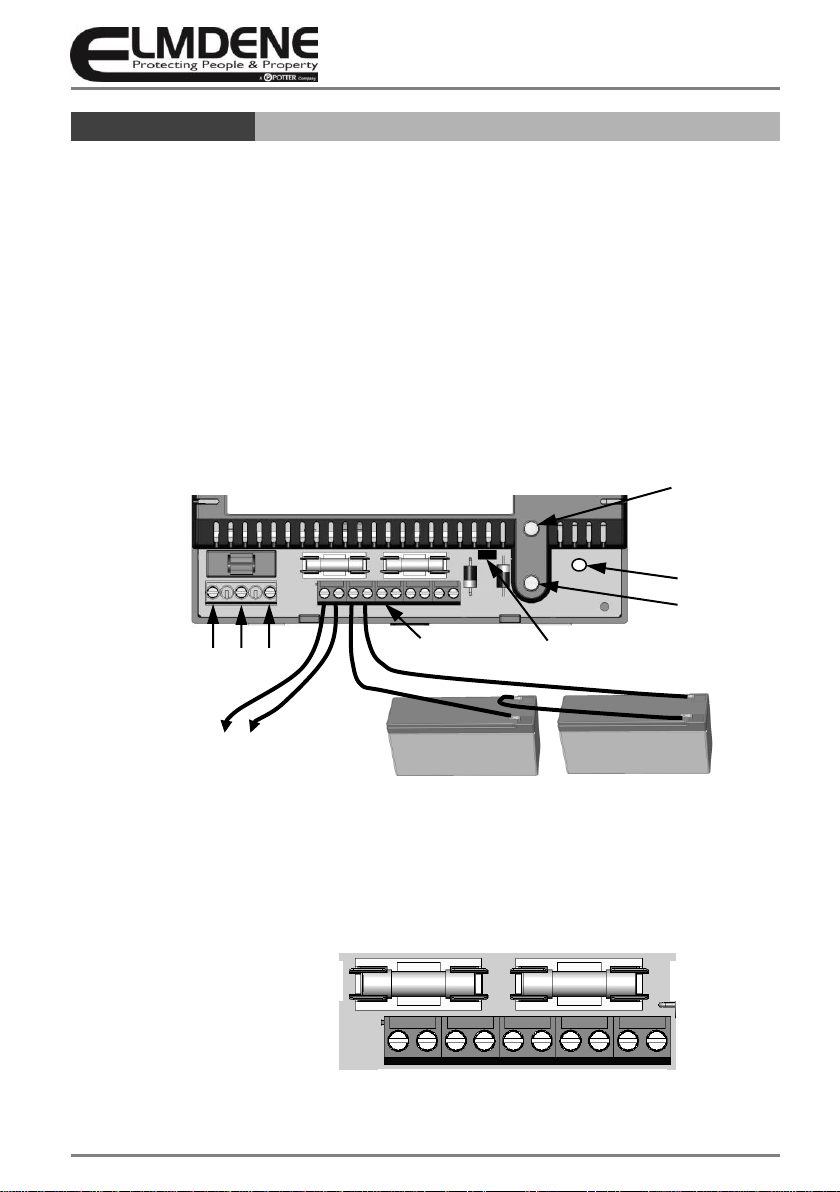

11) Connect the two 12 V standby batteries in series using the single cable provided. Connect the negative of

one battery to the positive of the other. See Figure 3.

CAUTION –DO NOT CONNECT the two remaining (free) battery terminals to each other!

12) Connect the PCB terminals Batt+ and Batt–to the free Positive and Negative terminals of the batteries

using the cables provided. See Figure 2 and 3. With the cable pair ALREADY screwed into the battery

terminals the FINAL connection MUST be to the battery itself.

CAUTION –significant energy can be released from an SLA battery. When connecting the last battery

lead, take extreme care to attach the cable ONLY to the correct terminal. Avoid shorting it to any other

terminal or conducting surface.

13) Verify that the yellow Fault LED does not flash (battery connection detected). Verify that the remote PSU

Fault monitor shows a closed contact.

14) Disconnect the mains power. Verify that the green Mains LED extinguishes and the Yellow Fault LED starts

to pulse (indicating that the PSE is running from its standby batteries).

15) If connected, verify that the EPS Fault monitor shows an open contact and the GEN PSU Fault monitor

shows a closed contact.

16) Verify that the standby batteries are now driving (supporting) the system load. Perform a full functional

test of system including full alarm condition Note: ensure batteries have sufficient charge to support the

system under full load.

Final

17) Reconnect the mains. Verify that the green Mains LED illuminates and the yellow Fault LED extinguishes.

18) If connected, verify that the EPS Fault monitor shows a closed contact and the GEN PSU Fault monitor

shows a closed contact.

19) Disconnect one of the battery leads, ensuring that no exposed section of conductor or connector is

allowed to contact exposed metal-work, other PSE terminals, or other battery terminals.

20) Verify that, in less than 1 minute, the yellow Fault LED starts to flash, and that the orange Diagnostic LED

flashes in a 2 pulse repeating pattern, (indicating that battery disconnection was detected).

21) Reconnect the battery lead and, after approximately 3 s, verify that that the Fault LED does not flash.

(Audible click can be heard as the battery relay closes, then a second click while the charger is tested.)

Note: If it is necessary to obtain confirmation of charging current; between steps 18 and 20, an ammeter

can be placed in series with the battery leads. Continue to observe caution with all exposed conductors

when inserting or removing the meter and when restoring normal battery wiring.

22) Close cover and secure using fastening screws provided.

In the event of loss of mains, a battery fault or a GEN PSU fault, the corresponding Fault signal contacts will

open.

If the output of the PSE fails, the cause of the failure should be investigated e.g. short circuit load,

connection of a deeply discharged battery. The fault should be rectified before restoring power to the PSE.

If any of the fuses require replacing, ensure the correct fuse rating and type is used.

This unit is intended for use by Service Personnel only. There are NO USER SERVICEABLE parts inside.

There is no regular maintenance required of the PSE other than periodic testing, and replacement of the

standby battery. Reference should be made to the battery manufacturer's documentation to determine

typical/expected battery life with a view to periodic replacement of the battery.