2

Pre-Delivery Inspection (PDI)

• BATTERY & CHARGER UNIT

1. The battery is a sealed unit and the casing should be checked to ensure it

is free from physical defect or damage.

2. The battery fuse holder should be checked to ensure that a correctly rated

(20AMP) fuse is present and working.

3. The key lock should be checked to ensure the correct key, barrel

movement, locking position and key removal can be obtained.

4. Examine and check that the charger unit is free from physical defect and

damage and is fitted with a U.K. plug and a 13amp fuse.

5. Ensure that charging begins and that the charger LED turns red. Place a

known fully charged battery on the bike and ensure the charger unit turns

yellow/green within a few minutes.

• BRAKES

6. The brake levers should be checked to ensure free movement and return

along with the correct seating of brake cable within the lever.

7. Brake cables should be checked to ensure free movement to the calliper,

that they are free from damage and that the cable locking nut on the

calliper is secure. Any excess cable should be tied or cut to a sensible

length and capped.

8. Locate and check brake blocks, ensure that they are correctly positioned to

make contact with the wheel rim and that the retaining nuts are secure.

9. Ensure that the front and rear brake callipers are correctly centred and

that the movement is smooth and effective in gripping the wheel rims.

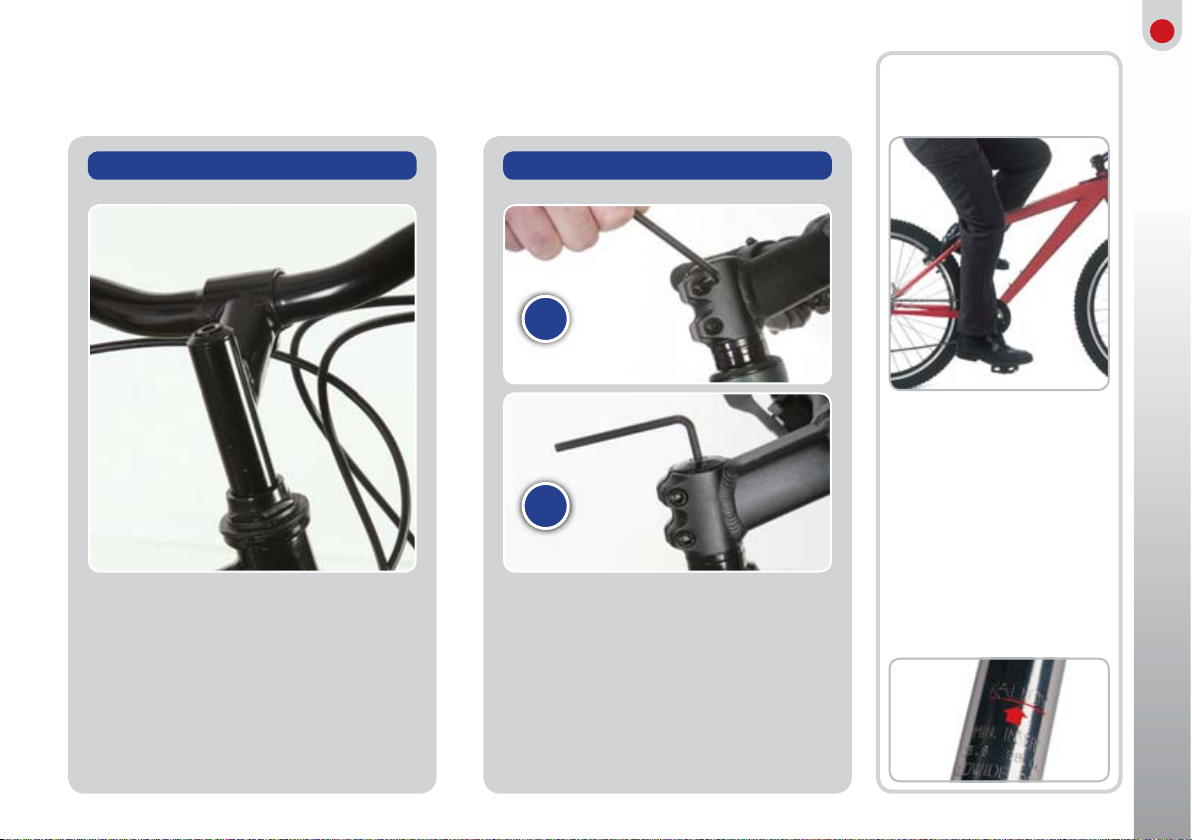

• BRAKE & ELECTRIC CABLES

10. Check to ensure that all cables are correctly routed, free from chaffing or

snagging and cable tied to the frame or handlebars as appropriate.

• CHAIN, CHAIN GUARD & SPROCKET

11. Check to ensure that the chain is correctly tensioned between the front

and rear sprockets and free from physical defect.

12. Where a speed gear sprocket is fitted. Ensure that the chain and gear

selector assembly moves freely and correctly through the gear selections

and that the gear selection mechanism is securely fixed to the handlebars.

13. Check to ensure that the chain guard is free from physical defect or

damage, that the guard is correctly positioned and that the retaining nuts

are secure.

• ELECTRIC MOTOR

14. The front hub motor should not need any specific examination, however

upon completion of all checks and assembly of the bike, the motor should

be tested as part of the final road test.

15. All electric connectors and retaining nuts on the assembly and cable feeds

should be checked to ensure that they are free from physical defect or

damage and that they are correctly positioned and tight.

PACKAGING

Powabykes are well packaged to prevent transport damage. Typically a bike

will be delivered in three master cartons, bike frame, front motor wheel

and battery. During transport a number of items are removed from the bike

e.g. The seat, front wheel, mudguards, handlebars, pedals and battery.

IMPORTANT SAFETY NOTICE

It is imperative that your new Powabyke or Powatryke is assembled and

adjusted for use by a qualified & authorised Powabyke dealer only. Failure to

comply with this stipulation may put your safety at risk and void the warranty.

Please consult with your dealer to ensure you have an adequate & legal

lighting system for your bike, and we would strongly recommend that you wear

a bicycle helmet. Finally, remember to post your warranty card to Powabyke.

The following items form part of the PDI procedure.

This must be carried out by the supplying dealer.