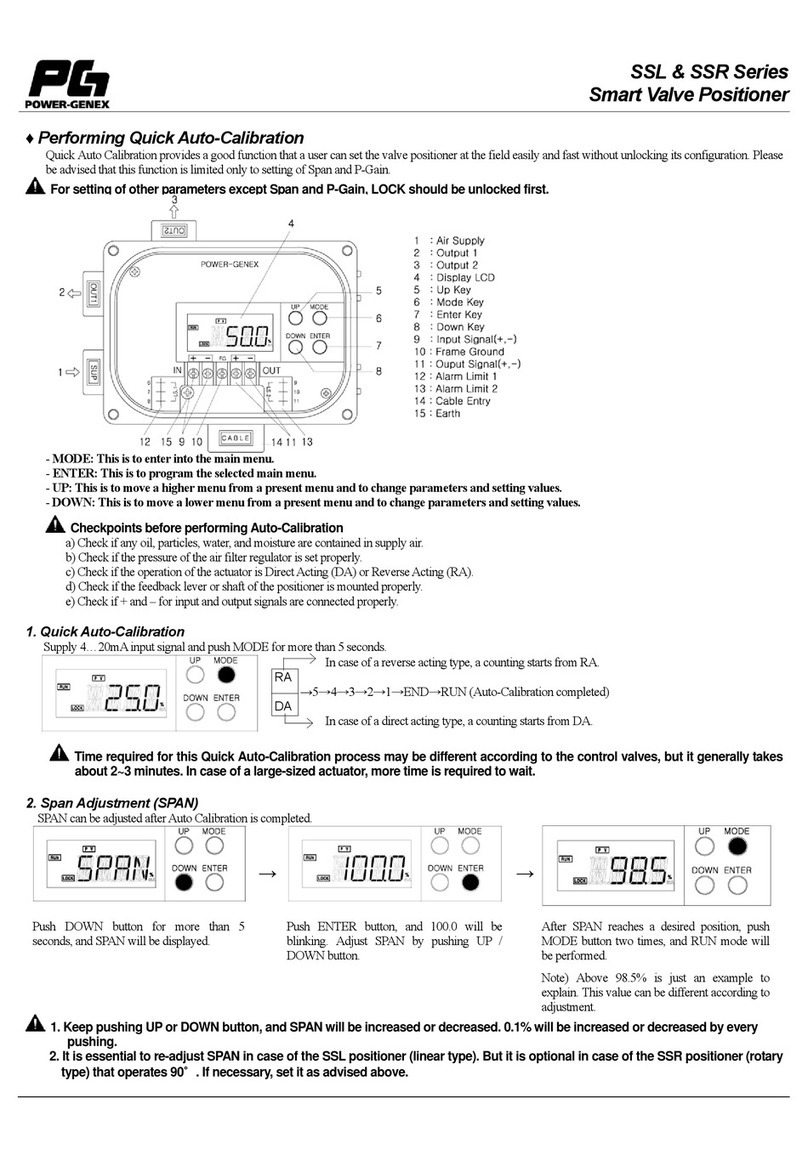

6. Span and Zero Adjustment

①Check the proper installation of the PPR positioner and the feedback shaft.

②Check the proper position of a cam according to the actuator type (direct acting or reverse acting).

③Connect all air connections.

④Supply air and set the input signal to 3psi. Turn the zero adjusting screw clockwise or counter clockwise to set the zero

position.

⑤Check the stroke of the control valve by setting the input signal to 15psi. If the stroke does not meet 100%, turn the span

adjusting screw clockwise or counter clockwise until 100% is reached.

⑥Set the input signal back to 3psi and adjust the zero adjusting screw until the zero point is reached.

⑦Repeat the process of ④to ⑥until the desired set points are reached.

⑧If the strokes of the control valve perfectly meet 0% and 100%, each setting point of 6, 9, and 12psi is

automatically reached.

7. Wire Diagrams for Position Transmitter and Limit Switches

CAUTION: Always check that the electrical load is within the range stated on the nameplate.

Failure to remain within electrical ratings may result in damage to or premature

failure of the electrical switches, sensors or transmitter electronics.

8. Position Transmitter (4…20mA output signal)

A. Board View

B. Specifications

Power Supply Rating 5.5 ~ 30V DC loop-powered

Recommended Power Supply 24V DC

Output Signal 4~20mA

Operating Temperature -20º to 70℃

Load Impedance 0~600 ohms

Max. Output 30mA DC

Linearity ± 1.0 %

Hysteresis 1.0 % of full scale

Repeatability ± 0.5 % of full scale

Adjustment Zero and Span in terminal box

C. With mA Loop calibrator D. With multimeter tester

E. Span and Zero Adjustment

①Select RA or DA on a board in the terminal box. For reference, RA (reverse acting) is a standard factory setting.

②Supply 4mA input signal and turn the zero adjusting screw on a board clockwise or counter clockwise until output signal

becomes 4mA.

③Supply 20mA input signal and turn the span adjusting screw on a board clockwise or counter clockwise until output

signal becomes 20mA.

④Repeat the process of ②to ③until output signal approaches input signal.

1. Be sure that Span and Zero of the EPR positioner should be exactly set before

setting Span and Zero of the position transmitter.

2. Be sure that 5.5 - 30V DC should be supplied in case of using the mA tester

(multimeter tester).

3. Check a loop power if the output power indicating lamp ⑥is not on.

9. Limit Switches (open and close)

Contacts SPDT Form C

AC Rating 16A 1/2HP 125/250VAC

DC Rating 0.6A 125VDC / 0.3A 250VDC

Adjustment Cams with set screws (L-wrench included for setting)

10. Optional Restricted Pilot Valve Orifice

WARNING: Before removing the pilot valve, be sure to disconnect the positioner from the

signal and compressed air source

For improved control using smaller actuators, a restricted pilot valve orifice kit is

included with the positioner. To install, the pilot valve must be removed from the

positioner. Remove four screws holding the pilot valve to the positioner body. As

you remove the pilot valve, be sure to hold the compensation spring in place.

Flip the valve so the bottom faces you. Remove the o-rings from the out 1 and

out 2 ports (as shown in the diagram at right). Place the orifice plates in their

place with new o-rings above them, and re-install the pilot valve, making sure

the compensation spring is back in place. The positioner is now set up for

smaller actuators.

11. Troubleshooting Tips

Troubles Solutions

There happens a hunting with a

small pneumatic actuator

The actuator is very small. Install two orifices at the bottom of the pilot

valve as instructed in 10. Optional Restricted Pilot Valve Orifice.

If the actuator is not small, check if a position shaft is inserted into the

output shaft of the actuator exactly. If there is a gap between these shafts,

make it tight.

The valve always opens

regardless of input signal.

The orifice of the Auto/Manual screw on the pilot valve is clogged.

Disconnect supply air and clean the orifice with a wire attached inside of

the EPR positioner cover as shown below.

Never move the seat adjuster. It was already set at the factory

precisely.

The valve always opens or

closes with input signal

The air connections are not made properly. Check again if the pneumatic

actuator type is RA (reverse acting) or DA (direct acting) and make the

proper air connections. See 7. Air Connections.

Linearity is very poor Re-set Zero and Span.

Hysteresis is very poor Tighten a mounting bracket.

12. Dimensions

Power-Genex Ltd.

44B9L, 434-9, Nonhyun-dong,

Namdong-gu, Incheon 405-848 Korea

Tel: +82-32-812-6644 Fax: +82-32-812-6645

www.powergenex.com sales@powergenex.com