Step1. Install Model 60‐012 Hitch following separate installation

instructionsprovidedwiththehitchitself.

Step2. Screws(item10)andNuts(Item6)onthedischargeChute

(Item 5) have been tightened before shipment to prevent possible

damage. The Screws and Nuts should be loosened just enough to

allow the Chute to swing upward feely as needed for storage or

transportingthroughnarrowpassageways.TheChuteshouldalways

bedownwhilemowing.

Step3. Mount cutting height adjustment lever (Item 41) on right

end of roller adjusting Shaft (Item 39) by inserting Screw (Item 45)

through Washer (Item 11), clevis end of Lever, and Shaft. Secure

withNut(Item46).ThenmoveLeverallthewayforwardintolowest

cuttingheightposition.

Step4. Withthenoseofthedeckpointingforward,slidethedeck

under the tractor from the right side as far as possible. Turnthe

frontwheelsallthewaytotheleftamdliftthedraglinkWeldment

(Item19)overtherightfrontwheel.

Step5. InsertasmallquickchangePin(Item29)throughthehole

in the lift arm of the tractor and through the end link of the Chain

(Item31)locatedonthetopofthedeck.

Step6. MovetheimplementLiftLeveronthetractortotherearin

ordertoraisethefrontofthedeck.

Step7. Align holes with welded spacers at front of drag link

Weldment(Item19)withthemiddleofthethreeholesatthelower

rearofthehitchandsecurewithablankBolt(Item18–HitchParts

List)andquickchangeKey(Item20–HitchPartsList).Moveliftlever

forwardtolowerdeck.

Note:Themiddleholeisusedforinitialinstallation.Asthebelt

stretcheswithuseitmaybedesirabletousetherearmosthole

in the hitch. If so, follow belt adjustment procedure provided

below.

Step8. Withthedeck loweredintooperating position, makesure

thatall6Rollers(Item48)aremakingcontactwiththelevelground.

Ontheleftsideofthedeck,measurethedistancefromthefronttip

oftheleftcuttingblade(Item75) to a flat, level ground surface.

Makethesamemeasurementfromthereartipofthesameblade.

Thedistanceshouldbethesame,frontandrear,onallthreeblades.

Ifthefronttipofthebladeislowerthantherear,loosentheouter

Nut(Item57)attherearofthescissorslinkRods(Items54and55)

andturntheinnerNut(Item57)againsttherolleradjustingpivotPin

(Item56)untiltheblademeasurementisthesameatfrontandrear

tips.Reversetheprocedureifthereartipofthebladeislowerthan

thefront.

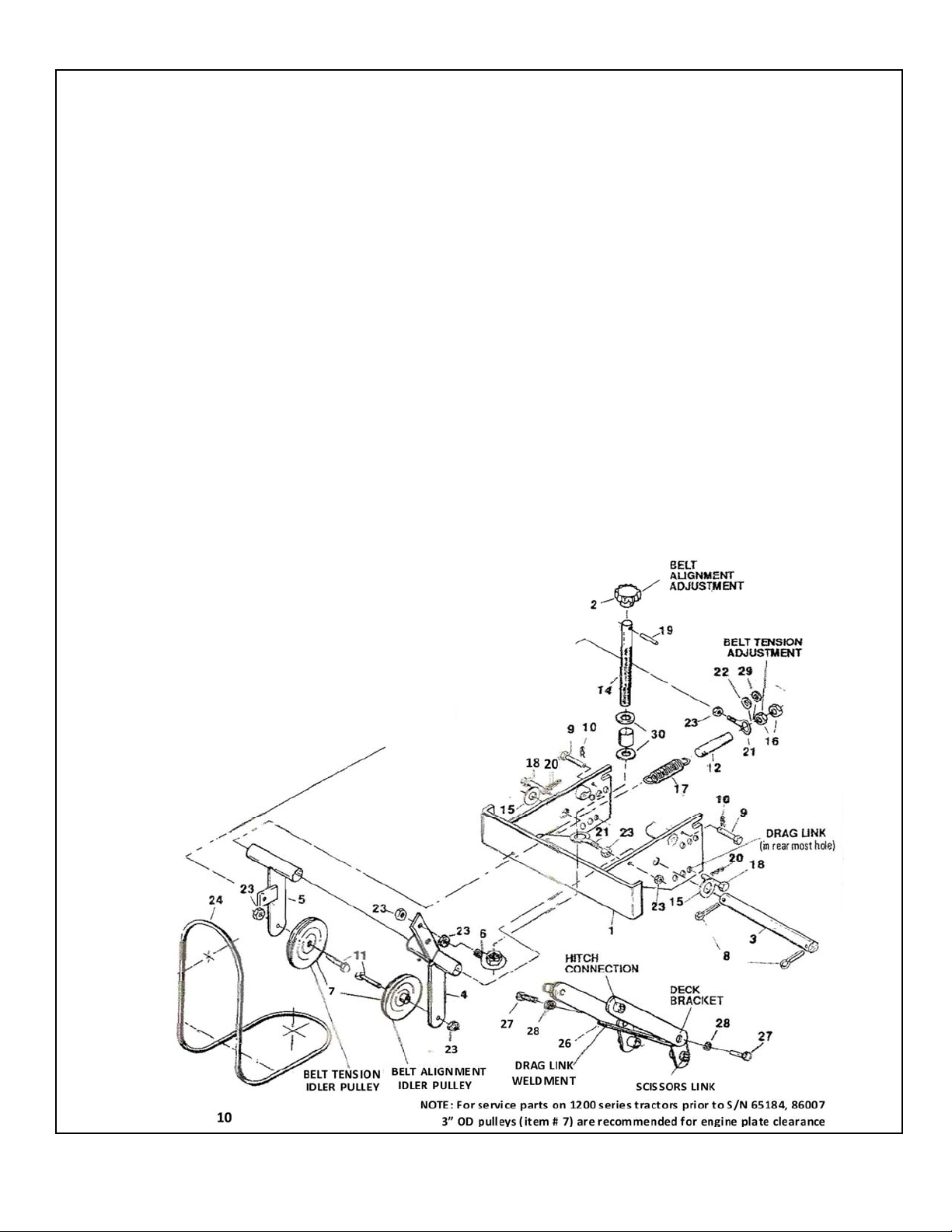

Step9. Facingthefrontofthetractorwiththeengineoff,loopthe

drive belt (Item 24 – Hitch Parts List) over the front groove of the

electromagneticclutchonthefrontoftheengine.Thenturnthebig

blackKnob(Item2–HitchPartsList)counterclockwiseenoughtoget

the drive Belt under the two Pulleys (Item 7 ‐ Hitch Parts List) and

aroundthetopgrooveofthecenterSpindle(Item1)ontopofdeck.

Step10. SetthecuttingheightadjustmentLevertomowershighest

cuttinglevel.TurnthebigblackKnobuntilthebeltonthesameside

astheKnobjustclears(1/8”)thenoseofthedeck.Alsochecktobe

sure the tension Spring (Item 17 – Hitch Parts List) controlling the

pulley on the other (left) side is tight with a little stretch on it.

TightenNut(Item16‐HitchPartsList)ontensionRod(Item12 –

HitchPartsList)ifnecessary.

Step11. SetthecuttingheightadjustingLevertothemowerslowest

cuttingheightandtightentheinnerNutonthebelttensionRoduntil

thetensionSpringisstretched3/8”toanapproximate length of 3‐

9/16”acrossthecoils.TightentheouterNutagainsttheinnerNutto

lockSpringatthatlength.

Step12. Whenoperatingmowerforthefirsttime.stopafterabout

15minutesandagainrecheckdecklevelandbeltalignment.

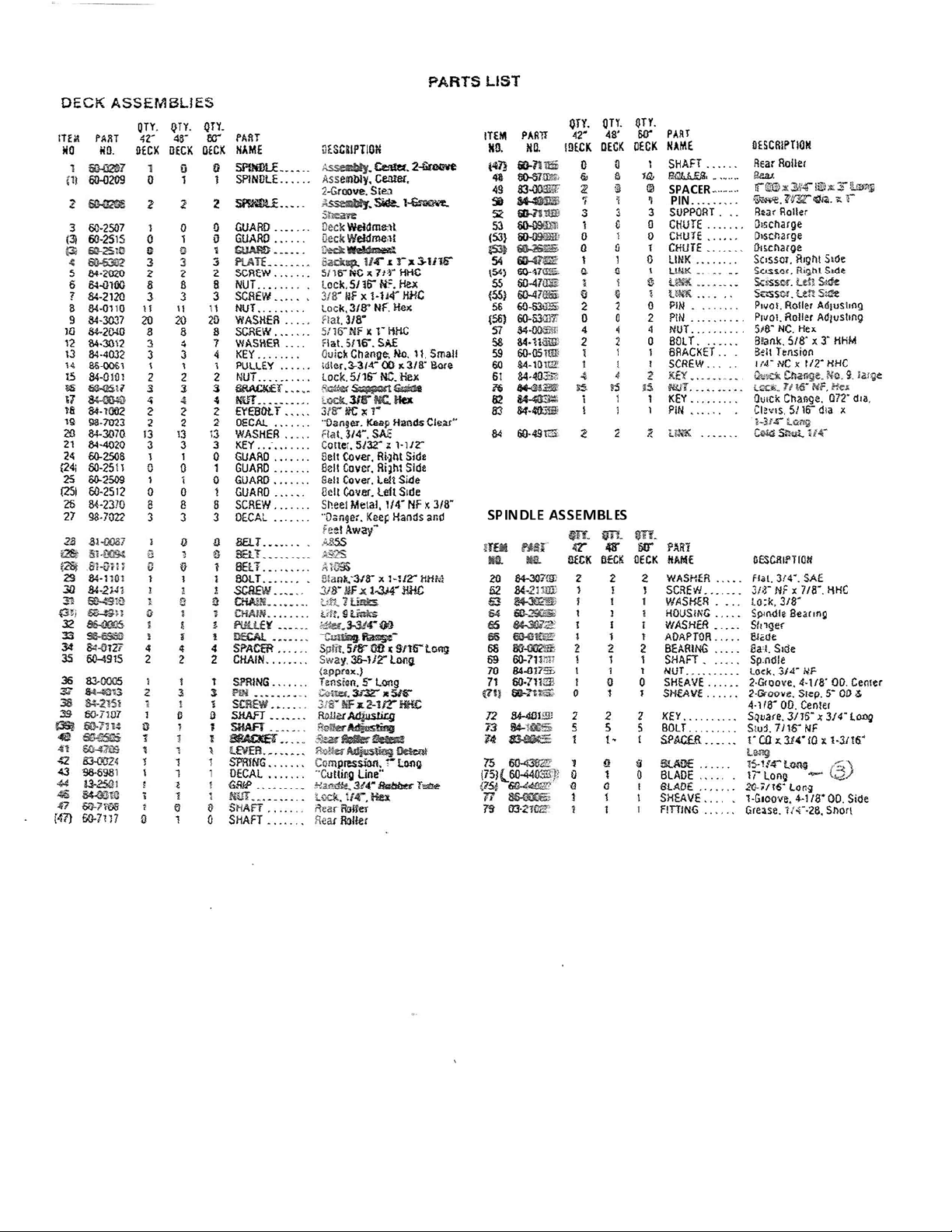

Lubrication

Toallowforwear,partsarelikelytofitsnuglywhentheyarenew.

Untiltheyhave“worn‐in”,theycanbemadetofunction

successfully with a few drops of lubricating oil at working joints.

Thereafter, especially after washing out under the deck, apply

lubricating oil to the linkage, rollers, and other pivot points

frequently. Spindles should be lubricated every 50 hours of

operation with a good multi‐purpose bearing grease. The grease

Fittings (Item 79) are located on each spindle Housing (Item 64)

underneath the deck. Wipe the Fitting clean before greasing to

preventdirtfrombeingforcedintotheBearings(Item68).Be

carefulnot tooverfillthe spindle since toomuchgrease pressure

maydamageseals.

CuttingHeight

ThelengthofthegrassaftercuttingisregulatedbytherearRollers

(Item 48). To adjust the position of the rear Rollers, raise the

mowerwiththeimplementliftHandleonthetractor(seeassembly

step6).Thenmovethecuttingheightadjustmentleverforwardto

lowertheheightofcutorrearwardtoraiseit.Lowerthemowerby

moving the implement lift Handle all the way forward. This will

allow all six rollers to rest on the ground. When transportingthe

deckfromthecuttingareatothestoragearea,setthecutting

heightadjustmentlevertothepositionmarkedwitha“T”.Thiswill

providemaximumgroundclearanceforallmowerpartsandprotect

thebladesanddeckfromdamage.

BladeCare

Always keep blades (Item 75) sharp and blade mounting Screw

(Item62)tight.Amaximumof22ft/lbs.oftorqueisrecommended.

NeverattempttotightenthebottomblademountingScrewortop

spindleNut(Item70)withouthavingthecuttingbladeinpositionto

prevent possible damage to the aluminium hub. To sharpen, file

alongtheoriginalbevel, usingcare nottofilematerialoff theend

as the length of the blade is important to maintain cutting circle

overlapandbladebalanceforacleancut.Whensharpening,check

balance of the blade with a rod or the shank of a screwdriver

through the center hole to see if both ends rest evenly. File the

heavysideuntileven.

BeltReplacement

After prolonged use, belts may show signs of wear by fraying or

cracking. If this occurs, the belt should be replaced as soon as

observedtopreventbreakingduringmowing.

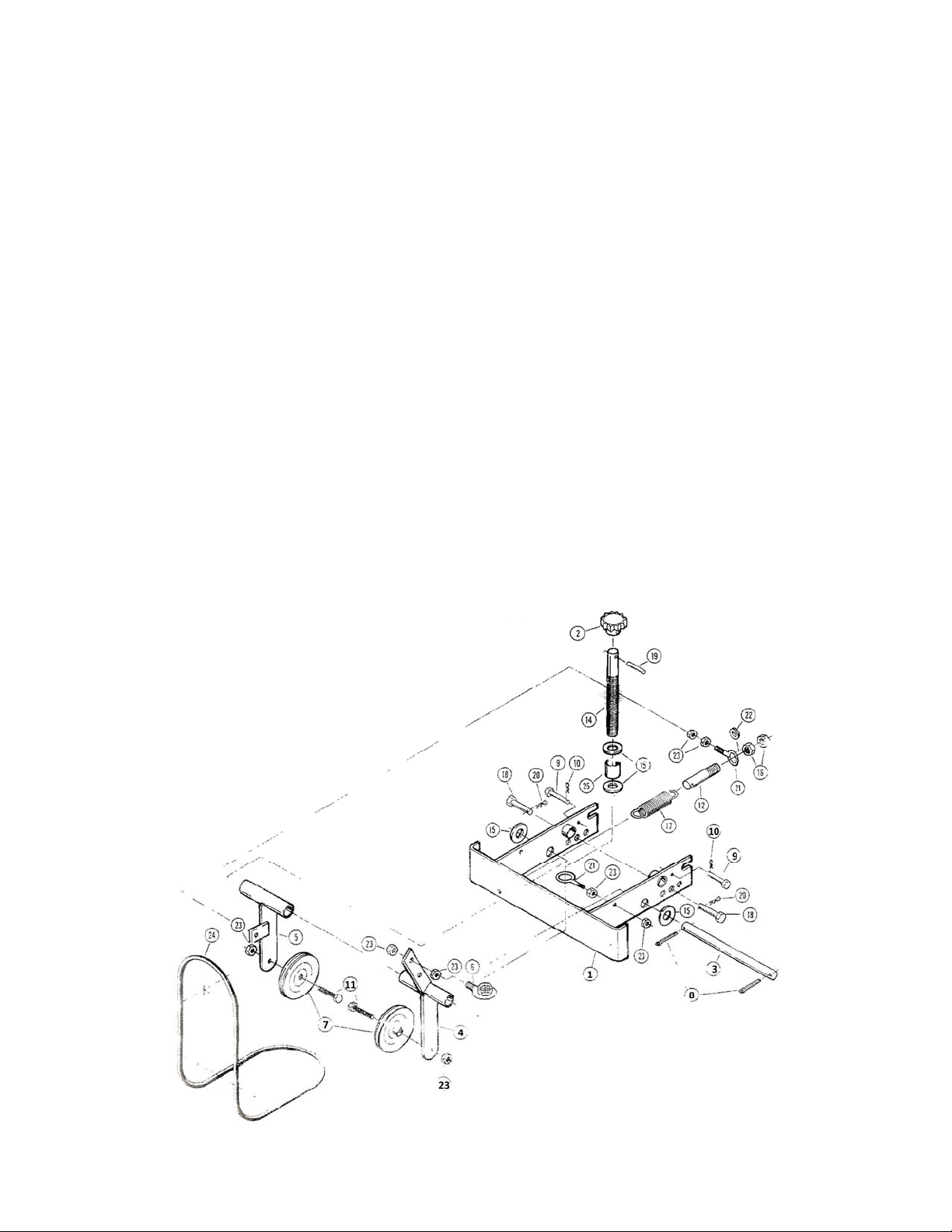

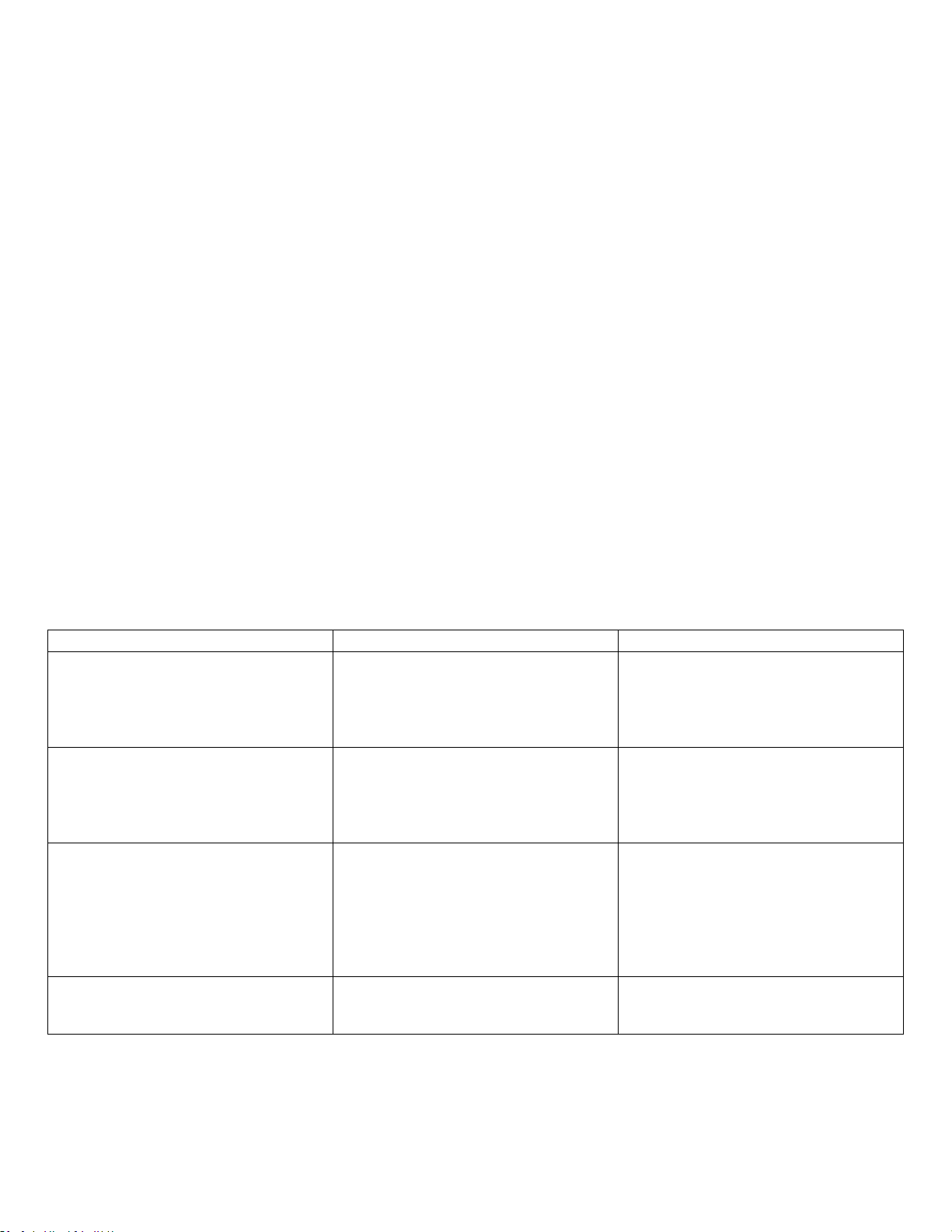

ToreplacethemowerCrossBelt(Item28),removebothbelt

Guards(Items24and25)andtheoldbelt.ThreadnewBeltaround

lower groove of the center spindle (Item 71), both left and right

sidespindles(Items2),andthetwoidlerPulleys(Items14and32)

as shown in exploded view drawing insert. Replace both belt

Guards.

ToreplacetheDriveBelt(Item24–HitchPartsList)turntheblack

serratedknobontheHitchcounterclockwisetoloosenthetension

onthebelt.Removetheoldbeltfromtheuppergrooveofthe

centerspindleonthedeckandthefrontmostgrooveofthepulley

ontheelectromagneticclutchonthefrontoftheengineandfeedit

throughthebottomoftheHitch.Refertosteps9–12for

reinstallationofthenewdriveBelt.