Power Master SI Series User manual

Stackable Inverter (SI series)

By Power Master

Sine Wave Inverter / ATS / Battery Charger /

Solar Charge controller (optional)

More Inverters stackable

3Phase connectable

USER MANUAL

USER MANUALUSER MANUAL

USER MANUAL

2

CONTENTS

Introduction .............................................................................................................................4

Specification ..............................................................................................................................7

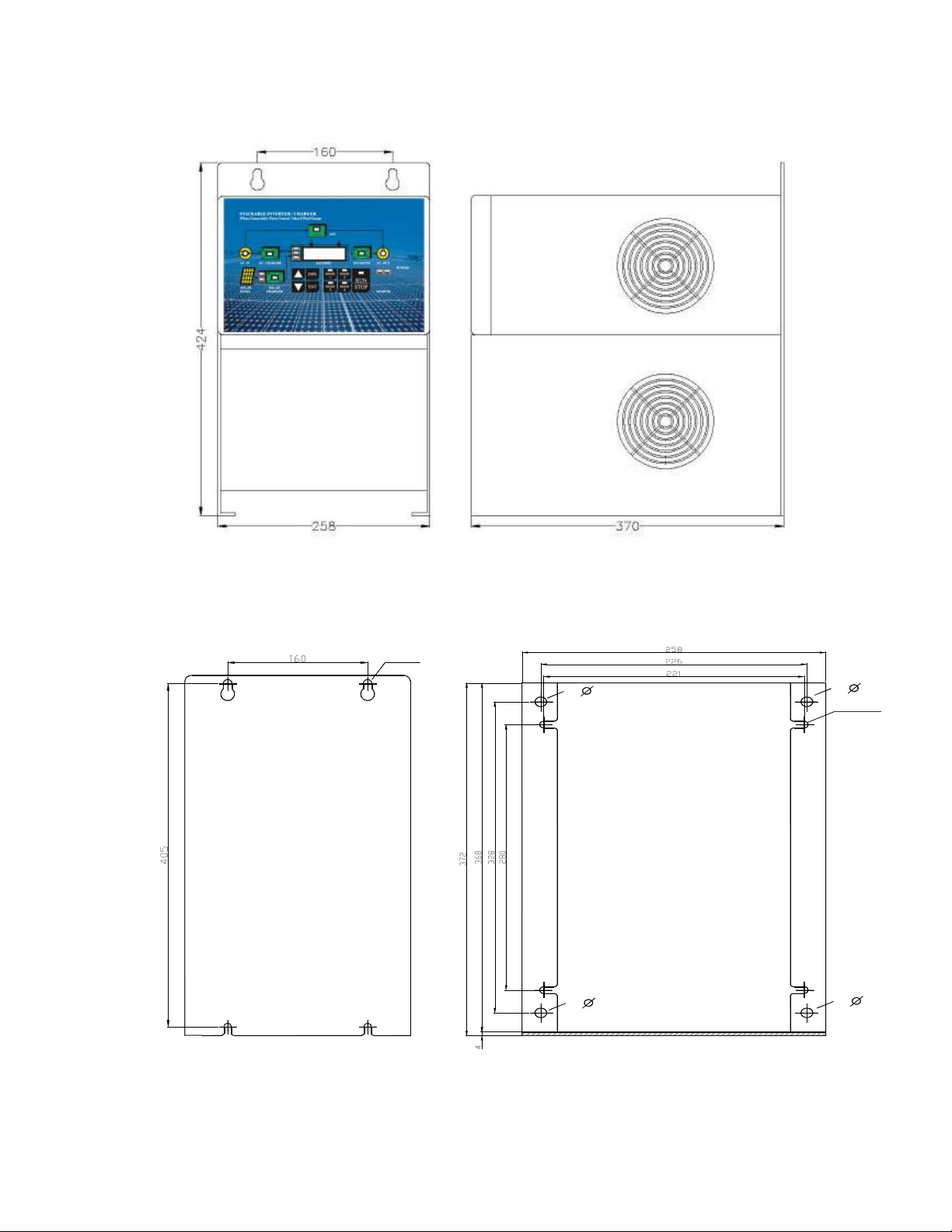

Dimension ..................................................................................................................................9

Chapter 1 Installation .............................................................................................................11

1.1 Box Contents ..................................................................................................11

1.2 Location..........................................................................................................11

1.3 Requirements .................................................................................................11

1.4 Connection of Battery Cables ........................................................................12

1.5 Connection of AC Cabling .............................................................................12

1.6 Optional Connections.....................................................................................13

1.7 Grounding ......................................................................................................14

1.8 Remote Control Panel (RCP-4) .....................................................................14

Chapter 2 Settings...................................................................................................................15

2.1 Four Control Modes Applicatioin ...................................................................15

MODE 1: AC Power as Priority Support .......................................................15

MODE 2: AC Generator Support with Dynamic Power Shifting..................18

MODE 3: Renewable Energy with Power Support ........................................20

MODE 4: Renewable Energy with AC Charger Backup Support.................23

Chapter 3 Wiring ....................................................................................................................25

3.1 Optional Fan Cover Application ...................................................................25

3.2 Upper-Front Panel Display............................................................................26

3.3 Lower-Front Panel Display............................................................................29

3.4 Battery Connection ........................................................................................30

3.5 Parallel Connection Schematic ......................................................................32

3.6 3-Phase Connection Schematic ......................................................................33

3.7 3-Phase System 15 Modules ...........................................................................34

Capter 4 User Constants .........................................................................................................35

4.1 Structure of User Constants ..............................................................................36

4.2 Operation Flow ..................................................................................................40

3

Chapter 5 Constants List ........................................................................................................48

U Group: Monitor..................................................................................................48

A Group: Initialize.................................................................................................49

B Group: General ..................................................................................................49

C Group: Inverter..................................................................................................50

D Group: Charger .................................................................................................50

E Group: Aux-Relay..............................................................................................51

F Group: Solar Charger ........................................................................................56

O Group: Operator................................................................................................56

Chapter 6 Programming Constants .......................................................................................62

A Group: Initialize.................................................................................................62

B Group: General ..................................................................................................64

C Group: Inverter..................................................................................................71

D Group: Charger .................................................................................................73

E Group: Aux-Relay..............................................................................................76

O Group: Operator................................................................................................82

U Group: Monitor..................................................................................................84

Chapter 7 Trouble Shooting Table.........................................................................................90

4

Introduction

General

Feature

The “Stackable Inverter” is a 3 in 1 multi-function module unit – True Sine Wave Inverter

built in programmable Battery Charger and Auto Transfer Switch (ATS). Besides these

primary functions, however, the Stackable Inverter has several advanced features that

provide a range of new applications as outlined below:

Uninterrupted Power deliver

In the event of a grid failure, or shore or generator power being disconnected, the inverter

within the Stackable Inverter is automatically activated and takes over supply to the

connected loads. This happens so fast (less than 10 milliseconds) that computers and other

electronic equipment will continue to operate without disruption.

More inverters stackable

Virtually unlimited power thanks to parallel operation up to 5 units can operate in parallel to

achieve higher power output. Five PM-3000SI-242 units, for example, provide 15kW of

output power with 350A charging capacity.

3 Phase connectable

In addition to parallel connection, three units of the same model can be configured for

three-phase output. But that’s not all: up to five sets of three units can be parallel connected

for a huge 45kW inverter and 1050A charger!

Power Control-Dealing with limited generator or shore side power

The “Stackable Inverter” is a very powerful battery charger. It will therefore draw a lot of

current from the generator or shore side power. A maximum generator or shore current can

be set (B2-05). The “Stackable Inverter” will then take account of other AC loads and use

whatever is extra for charging thus preventing the generator or shore supply from overload.

Power Assist-Boosting the capacity of shore or generator power

This feature takes the principle of Power Control to a farther dimension allowing the

“Stackable Inverter” to supplement the capacity of the alternative source. Where peak

power is so often required only for a limited period; it is possible to reduce the size of

generator needed or conversely enable more to be achieved from typically limited shore

connection. When the load reduces, the spare power is used to recharge the battery.

5

Battery Charger

Adaptive 4-stage charge characteristic: Bulk-Absorption-Float-Equalize

The “Stackable Inverter” features a microprocessor controlled “adaptive” battery

management system that can be preset to suit different types of batteries. The “adaptive”

feature will automatically optimize the process relative to the way the battery is being used.

The right amount of charge: Variable Absorption Time

When only shallow discharges occur (a yacht connected to shore power for example), the

absorption time is kept in order to prevent overcharging of the battery. After a deep

discharge, the absorption time is automatically increased to make sure that the battery is

completely recharged.

Preventing damage due to excessive gassing: The Battery Safe Mode

If, in order to quickly charge a battery, a high charge current in combination with a high

absorption voltage has been chosen. The “Stackable Inverter” will prevent damage due to

excessive gassing by automatically limiting the rate of voltage increase once the gassing

voltage has been reached.

Less maintenance and aging when the battery is not use: The Equalize Mode

The equalize mode kicks in whenever the battery has not been subjected to discharge during

24 hours. In the equalize mode, float voltage is reduced to 2.2V/cell (13.2V for 12V battery)

to minimize gassing and corrosion of the positive plate. One a week, the voltage is raised

back to absorption level to “equalize” the battery. This feature prevents stratification of the

electrolyte and sulphation, a major cause of early battery failure.

2 outputs to charge 2 battery banks

The “Stackable Inverter” features 2 outputs, of which 1 can carry the full output current.

The second output, limited to approximately 4A and with a slightly lower output voltage, is

intended to top up a starter battery.

To increase battery life: Temperature Compensation

Every “Stackable Inverter” comes with a battery temperature sensor (BTS-3) when

connected, charge voltage will automatically decrease with increasing battery temperature.

This feature is especially recommended for sealed batteries and/or when important

fluctuation of battery temperature is expected.

6

Battery Voltage Sense

In order to compensate for voltage loss due to cable resistance, the “Stackable Inverter” is

provided with a voltage sense facility so that the battery always receives the correct charge

voltage.

Extensional Solar Charger

Stackable Inverter also provides the availability of up to 10 sets of Solar Charger, PM SCC

45A or PM SCC 60A (optional) to be used with solar panel to charge the battery. Stackable

Inverter sends the 4-stage charging command to extensional Solar Charger via port C

(Extension Port) for the best quality of solar charging.

7

Specification

MODEL

12 Volt System

24 Volt System

48 Volt System

PM-1500SI-12X (1)

PM-1500SI -24X

PM-1500SI -48X

PM-3000SI -12X (1)

PM-3000SI -24X

PM-3000SI -48X

GENERAL

Ventilation Forced cooling Forced cooling

Temperature

–Operation

–Storage

-20℃~ +70℃

-25℃~ +80℃

-20℃~ +70℃

-25℃~ +80℃

Protection

a. Output short circuit ˇˇ

b. Over load ˇˇ

c. Battery voltage too high ˇˇ

d. Battery voltage too low ˇˇ

e. DC voltage ripple too high ˇˇ

f. Temperature Sensor

Transformer ˇ(105℃)ˇ(105℃)

Electronic & Powerstage ˇ(70℃)ˇ(70℃)

BTS-3 ˇ(50℃)ˇ(50℃)

Humidity 0~95% (non condensing) 0~95% (non condensing)

Power control Function ˇˇ

Power assist Function ˇˇ

Uninterrupted AC power ˇ (less than 10 msec) ˇ (less than 10 msec)

Adaptive 4-stage charge ˇˇ

Two output to charge 2 battery banks ˇˇ

Auxiliary Relay X 3 X 3

Parallel operation ˇ(Max. 5 sets) ˇ(Max. 5 sets)

3-phase capacity ˇˇ

Battery voltage sensor ˇˇ

Battery Temperature sensor (BTS-3) ˇˇ

Remote control port ˇˇ

Extension Port (Port C) ˇˇ

INVERTER

Input Voltage Range (VDC) 9.5 -16V / 19-32V / 38-64V

Output Voltage (VAC) 185~240 VAC / 90~120 VAC

Output Frequency 50Hz /60Hz ± 0.1%

Output Waveform Pure sinewave

8

(1) X should be 1, output voltage = 90~120 VAC or 2, output voltage = 185~240 VAC

Output Voltage THD <5%

Power Factor (All Loads) ˇ

No linger load, crest factor 3: 1

Cont. Power Output (W)

Under 70℃(cosθ=1.0)

1500W

(No derate)

3000W

(No derate)

Cont. Power Output (W)

Over 70℃(cosθ=1.0)

0W

(Shutdown)

0W

(Shutdown)

Maximum Power (W) 3000W 6000W

Maximum Efficiency (%) 82/84/85 84/86/89

Zero-load Power (W) 12W 18W

CHARGER

Input Voltage Range (VAC) 200~250 VAC / 100~125 VAC

Input Frequency 45-55Hz /55-65 Hz

Power Factor 1

Charge Characteristic 4-stage adaptive / Bulk-Absorption-Float-Equalize

Maximum DC Voltage Ripple (Vrms) < 1.25 V

Charge Current House Battery (A) 70A/40A/20A 140A/70A/40A

Charge Current Starter Battery (A) 4A

Absorption Voltage Default (VDC) 14.4V / 28.8V / 57.6V

Float voltage Default (VDC) 13.8V / 27.6V / 55.2V

Equalize Voltage default (VDC) 13.2V / 26.4V / 52.8V

Output Charge Voltage (min ~ max) 8V~16V / 11V~32V / 22V~64V

Battery Temperature sensor BTS-3

AC INPUT SWITCH

AC IN Terminal Circuit Breaker 15A (120V) /15A (230V) 30A (120V) /15A (220V)

Switch-over Time

a. inverter to AC input 0 msec.

b. AC input to inverter 0 msec.

Detection Time AC Input Fault 4 ~10 msec.

Trip Level AC Input to Inverter 90 VAC / 180 VAC

Trip Level Inverter to AC Input 94 VAC / 187 VAC

Min.~ Max. Frequency Range 45-55 Hz / 55-65 Hz

MECHANICAL

Cabinet / Protecting Class Aluminum / IP20

Dimension (HXWXD) 362 x 258 x 370 mm 424 x 258 x 370 mm

Weight (kgs) 30 kgs 35 kgs

9

Dimension

PM-1500SI-12/24 Unit: mm

Installation Holes

Backside Mounting Holes Bottom Mounting Holes

1 0

10

10

1 0 M 6 -4

M8-4

10

PM-3000SI-12/24 Unit: mm

Installation Holes

Backside Mounting Holes Bottom Mounting Holes

1 0

10

10

1 0 M 6 -4

M8-4

11

Chapter 1 Installation

This product should be installed by a qualified electrician.

1.1 Box Contents

Stackable Inverter

USER MANUAL

Bag Containing connection items, ie:

Battery Temperature Sensor (BTS-03)

Four M8 nuts (including spring washers)

Four terminals and casing

1.2 Location

The product must be installed in a dry and well-ventilated area, as close as possible to

batteries. There should be a clear space of at least 20 cm around the appliance for cooling.

Excessively high ambient temperature will result in the following

Reduced service life

Reduced charge current

Reduced peak capacity or shutdown of the inverter

Never position the appliance directly above the batteries.

The product is suitable for wall mounting. The back and the bottom of the enclosure has

holes for wall mounting purposes, see Page 9 and 10.

The appliance can be mounted horizontally as well as vertically; vertical mounting is

preferable. Te vertical position offers optimum cooling.

The interior of the product must remain accessible after installation. Ensure the AC

and DC input cables are fitted with fuses and circuit breakers. Try and keep the

distance between the product and battery to a minimum in order to minimize cable

voltage losses.

For safety purpose, this product should be installed in a heat-resistant environment if

it is used with equipment where a substantial amount of power is to be converted. You

should prevent the presence of e.g. chemicals, synthetic components, curtains or

textiles, etc. in the immediate vicinity.

1.3 Requirements

Screwdrivers for removing the lower-front panel and connecting AC loads.

2 battery cables (maximum length 6 meters)

12

Including battery terminals and cable ends.

Insulated box spanner (13 mm) for securing the DC terminal nuts.

Three-wire cable for AC cabling.

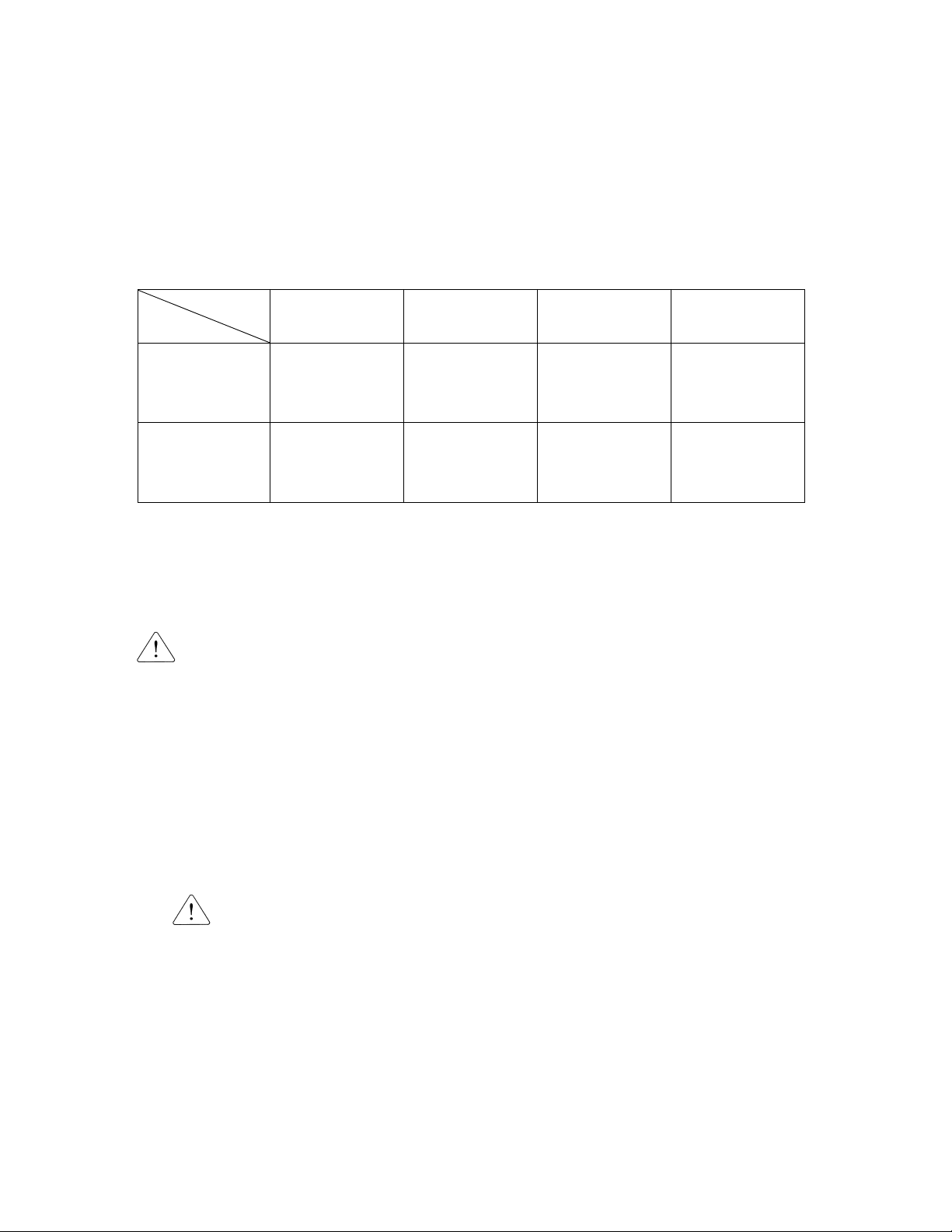

1.4 Connection of Battery Cables

In order to fully utilize the full capacity of the product, batteries with sufficient capacity and

battery cables with sufficient cross section should be used, please see table:

Model

Item PM-1500SI-12X

PM-1500SI-24X

PM-3000SI-12X

PM-3000SI-24X

Recommended

battery capacity

(Ah)

200~700 100~400 400~1200 200~700

Recommended

cross section

(mm2)(0~6m)

50 mm238 mm280 mm250 mm2

Remark: Internal resistance is the important factor when working with low capacity batteries.

Consult your supplier.

Procedure:

Proceed as follows to connect the battery cables:

Use an insulated box spanner in order to avoid shorting the battery.

Avoid shorting the battery cables:

Undo the four screws at the lower-front panel of the enclosure and remove the panel.

Connect the battery cable: the + (red) on the right and the – (black) on the left. Please

see page 30 and 31.

Don’t reverse the (+) and (-) of the battery. This may cause internal damage.

Tighten the connections after positioning the fastening items supplied with product.

Secure the nuts tightly in order to reduce the contact resistance as much as possible.

1.5 Connection of AC Cabling

The enclosure must be grounded for safety purpose. An earth screw has been fitted at

the bottom side of the enclosure.

The terminal block can be found at lower-front panel of the enclosure: The shore or mains

(AC IN) cable must be connected to AC IN terminals, use a three-wire cable and a cross

section of 4~10 mm2.

Procedure:

Proceed as follows to connect the AC cables.

The AC output cable can be connected directly to terminal block containing the word

13

“AC OUT”. The terminal points are indicated clearly. From left to right: “G” (earth),

“N” (neutral), and “L” (phase).

The AC input cable can be connected to the terminal block containing the word “AC

IN”, the terminal points are indicated clearly from left to right “L” (phase), “N”

(neutral), and “G” (earth).

The current which is switched through to the output (AC OUT) is not fused.

External fuses or current limiters have to be installed.

1.6 Optional Connections

A number of operational connections are possible:

1.6.1 Second Battery

The “Stackable Inverter” has a connection for charging a starter battery.

For connection, see page 29.

1.6.2 Voltage Sense

Two sense wires may be connected to compensate possible battery cable losses during

charging. Use wires of at least 0.75 mm2. For connection, see page 29.

1.6.3 Battery Temperature Sensor (BTS-3)

The battery temperature sensor supplied with the product may be used for temperature

compensated charging, see page 29.

The sensor is insulated and must be mounted on the batteries minus pole.

1.6.4 3 Sets of Auxiliary Relay (RY1, RY2, RY3) Output

The “Stackable Inverter” provides 3 sets of Auxiliary Relays for users to connect to

other appliances or to output the alarm signals. 3 sets of relays can be programmed for

respective function. (E Group Constants) and can be practically applied which is one of

the greatest features.

1.6.5 Parallel Connection

The product can be connected in parallel using several identical modules, please see

page 32. The batteries must be connected in accordance with page 32.This requires

interconnecting the products with the package of a special box, parallel box, to be

supplied by factory in conjunction with a connection diagram.

Parallel connection requires compliance with the following conditions:

1. No more than 5 units should be connected in parallel.

2. Only identical models should be connected in parallel.

3. Ensure sufficient battery capacity is available.

4. The prescribed cable cross sections (between battery and distribution point) must

be multiplied with the number of appliances to be connected in parallel.

5. Position the products close to each other but ensure there is adequate clearance for

ventilation minimum 20 cm. For better ventilation, please install the fan cover

14

(optional).

6. The BTS, voltage sensor and remote control panel (RCP) must be connected to

Master.

7. The cables for each appliance must be equal in length (AC and DC)

1.6.6 3-Phase Operation

The product can also be used in a 3-phase system, see page 33. The batteries must be

connected in accordance with page 33. The following condition conditions should be

complied with in the case of 3-1phase operation:

1. Only identical models should be used.

2. Ensure sufficient battery capacity is available.

3. Position the products close to each other but ensure there is adequate clearance for

ventilation minimum 20 cm.

(For the better ventilation environment, it is highly recommended to install the fan

cover in the air-in on the right side of Stackable Inverter.

4. The BTS, voltage sensor should preferably be connected all three units (1 Master

unit and 2 Follower units).

5. Only a single remote control can be connected.

1.7 Grounding

When the input voltage of the Stackable Inverter is not switched through, the neutral of “AC

OUT” is connected to ground by means of a relay. This function can be disabled by constant

B2-07 (B2-07=0 Disconnect)

1.8 Remote Control Panel (RCP-4)

The product can be operated remotely from remote port with the aid of a remote control

panel. For connection of a remote control panel, see page 28.

Note: The display panel and operation flow of the remote control panel is exactly the same as

the upper-front display panel.

15

Chapter 2 Settings

Settings may only be changed by a qualified engineer.

Carefully read the user manual before any change is made.

When setting the charger, all connections to the battery must be disconnected from the

Stackable Inverter.

Do not use non-rechargeable batteries.

Batteries should be placed in a dry and well-ventilated area during charging.

The product default settings are for charging gel batteries. For the recommended battery

voltage initial settings, see D1 (Charger) Group parameters.

2.1 Four Control Modes Applications

MODE 1: AC Power as Priority Support (Example of PM-3000SI-242)

When Stackable Inverter enters to MODE 1, B2-09 (AC IN DynaCur Limit)=0 (Disable) and

the value of B2-18 (MODE1: ACINCurrent Lmt) will be loaded to B2-05.

1. INVERTER Mode:

When AC IN=0 A, AC OUT load is completely supplied by INVERTER. It goes to the

inverter mode.

Battery

Grid,Shore,G enerator

Power Load

ATS O FF

AC IN AC O UT

5A

5A

0A

75A

16

2. Power Control Mode (a)

In this example:

All AC loads are off, with the “Stackable Inverter” constant B2-05=5A (AC IN Current

Limit),

the AC CHARGER will not take more than 5A with limits to battery charge current to

75A.

3. Power Control Mode (b)

Now some small loads are switched on and load increase to 3A. Only 5-3=2A is left to

charge the batteries and charge current is reduced to about 30A.

※ Note: Shore current is automatically limited to 5A and the AC input circuit

breaker will not trip!

Battery

Shore Power

M ax 5A Load

ATS ON

AC IN AC OUT

5A

5A

0A

75A

5A

B2-05=5A

17

Battery

Shore Power

Max 5A Load

ATS ON

AC IN AC OUT

5A

2A

30A

5A

B2-05=5A

3A

18

4. Power Control Mode (c)

The load is switched on and current consumption increase to 5A. Nothing is left to charge

the battery.

The charge current is automatically reduced to 0A, and the AC input circuit breaker does

not trip!

Battery

Shore Power

Max 5A Load

ATS ON

AC IN AC OUT

5A

0A

5A

B2-05=5A

5A

5. Power Assist Mode

And now the other load adds and switches on and the current increases to 11A. This is

where Power Assist is needed.

The bidirectional converter starts operating as inverter to add 6A to the 5A that is

available from the shore-side: Total 6+5=11A, and no overload on the AC supply.

As soon as the load reduces to less than 5A, any current that is left over will be used to

recharge the battery.

Battery

Shore Power

Max 5A Load

ATS ON

AC IN AC OUT

5A

6A

5A

B2-05=5A

11A

90A

19

MODE 2: AC Generator Support with Dynmaic Power Shifting

(Example of PM-3000SI-242)

When Stackable Inverter enters to MODE 2, B2-09(AC IN DynaCur Limit)=1 (Enable) and

the value of B2-21 (MODE 2: ACINCurrent Lmt) will be loaded to B2-05.

1. INVERTER Mode:

When AC IN=0 A, AC OUT load is completely supplied by INVERTER. It goes to the

inverter mode.

Battery

Grid,Shore,Generator

Power Load

ATS OFF

AC IN AC OUT

5A

5A

0A

75A

2. Power Control Mode (a)

In this example:

All AC loads are off, with the “Stackable Inverter” constant B2-05=5A (AC IN Current

Limit),

the AC CHARGER will not take more than 5A with limits to battery charge current to

75A.

Battery

Shore Power

Max 5A Load

ATS ON

AC IN AC OUT

5A

5A

0A

75A

5A

B2-05=5A

20

3. Power Control Mode (b)

Now some small loads are switched on and load increase to 3A. Only 5-3=2A is left to

charge the batteries and charge current is reduced to about 30A.

※ Note: Shore current is automatically limited to 5A and the AC input circuit

breaker will not trip!

Battery

Shore Power

Max 5A Load

ATS ON

AC IN AC OUT

5A

2A

30A

5A

B2-05=5A

3A

4.Power Control Mode (c)

The load is switched on and current consumption increase to 5A. Nothing is left to charge

the battery.

The charge current is automatically reduced to 0A, and the AC input circuit breaker does

not trip!

Battery

Shore Power

Max 5A Load

ATS ON

AC IN AC OUT

5A

0A

5A

B2-05=5A

5A

This manual suits for next models

6

Table of contents

Other Power Master Inverter manuals