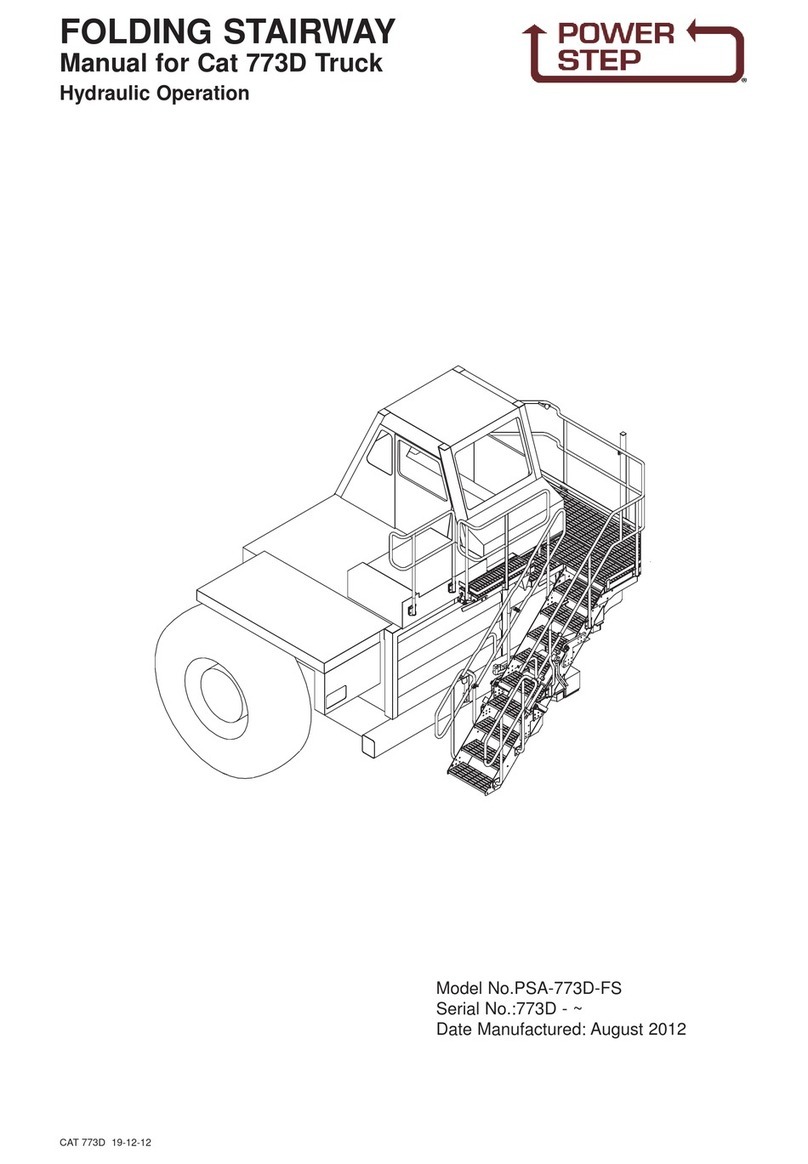

FOLDING LADDER

Caterpillar D10R Dozer

Section 1 Installation Instruction Drawings - 22 054

See Drawings 22 054 - Page 6 & 7

Pg5

PSA-D10R FL+RHW 31-3-14

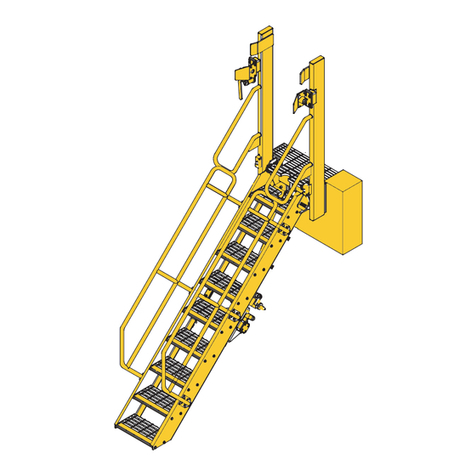

Procedure

1. Fit Mounting Blocks per Drg 22 053

2. Per REAR VIEW: Fit Spreader Plate 22 287 to rear mounting blocks. Use Washer

Plates 22.281 and washers under bolt heads.

3. Per VIEW 4A & 4B, Isolators: Fit Isolators 21 930 to Rear Spreader Plate. (See also

REAR VIEW). Per SIDE VIEW also fit Isolators 21 930 to Side Mounting Pads. On

left side fit Side Landing 22 017 with Ladder Shaft and Drive already assembled,

supported by Isolators. Fit Isolator Pin Bracket/s to arm at rear of landing beam with

pin to provide torsional restraint. Similarly fit Side Landing 22 016 on right side.

Note that there are two patterns of Isolator Pin Bracket bolted under the beams of

the Side Landings, 22 014 98 (shallow) at the rear and 22 014 99 (deep) at the

front. Both are orientated so the hole for the isolator pin is close to the machine

rather than away from the machine.

4. Fit Ladder. Using Spacers (within Actuator Cylinder Mounting 21 954), adjust drive

so gears are not loaded when ladder is lowered.

5. Per SIDE VIEW, REAR VIEW and VIEW 5, PROP System:

Attach PROP System Mounting Frame 22 0013 atop cabin, on ROPS unless similar

is already fitted by customer. Mount PROP 21 945 using middle holes (of set of 5).

Try Ladder with PROP. Ladder and PROP must align (longways with machine).

Adjust position of isolator mounting pads on frame if necessary then weld pads to

frame with 6cfw across top of frame rhs member ie where visible from above.

Adjust position of PROP (using choice of holes in set of 5) so ladder lies against

buffers when fully raised without loading the drive gears ie, with light manual effort

the ladder can be moved away from the buffers.

6. Per PLAN/SIDE/REAR VIEWS, fit Rear Walkway 22 051 & Handrails.