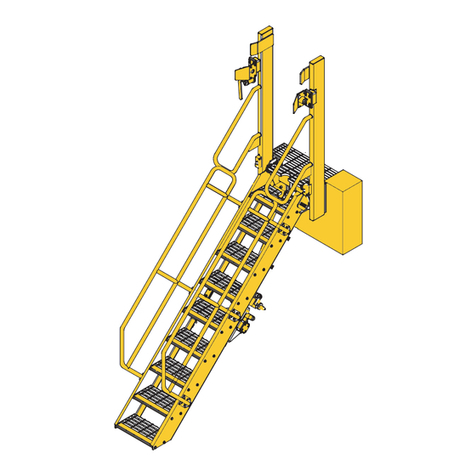

Power Step D10T User manual

Other Power Step Ladder manuals

Power Step

Power Step LeTourneau L1850 User manual

Power Step

Power Step PSA-EX2500-FRS User manual

Power Step

Power Step PSA-EX3600-FRS User manual

Power Step

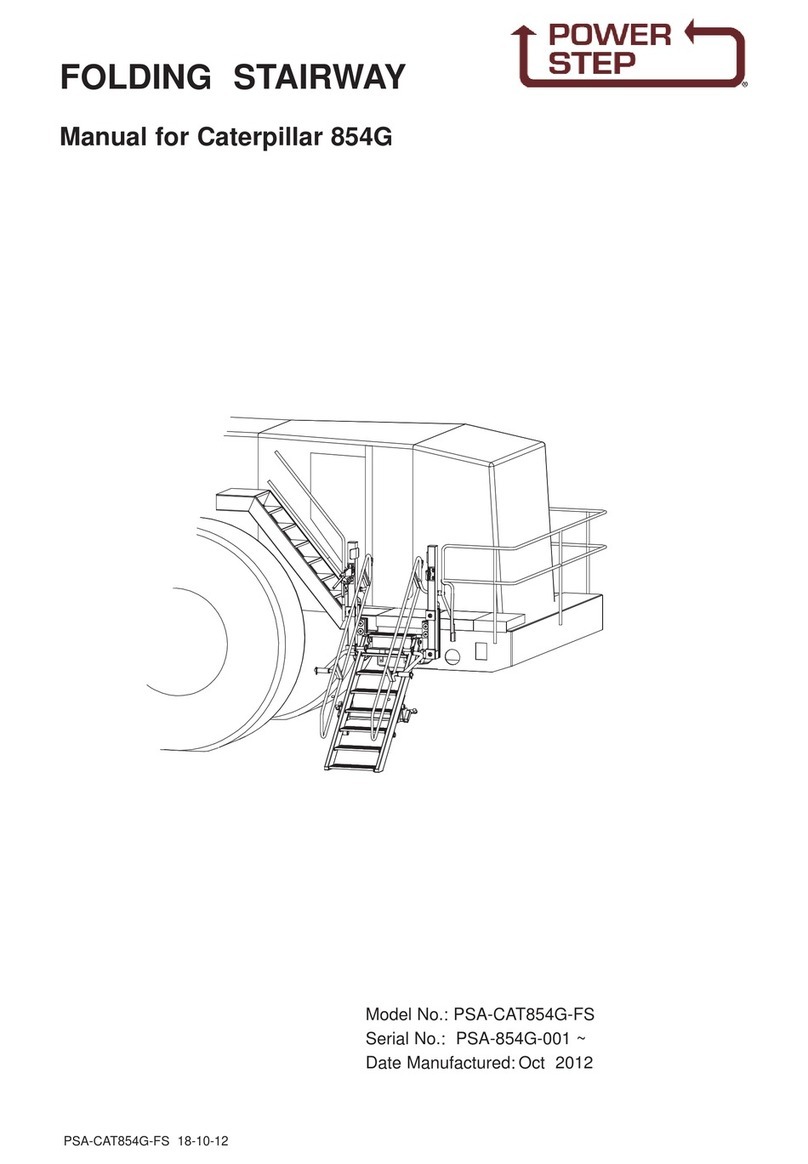

Power Step Caterpillar 854G User manual

Power Step

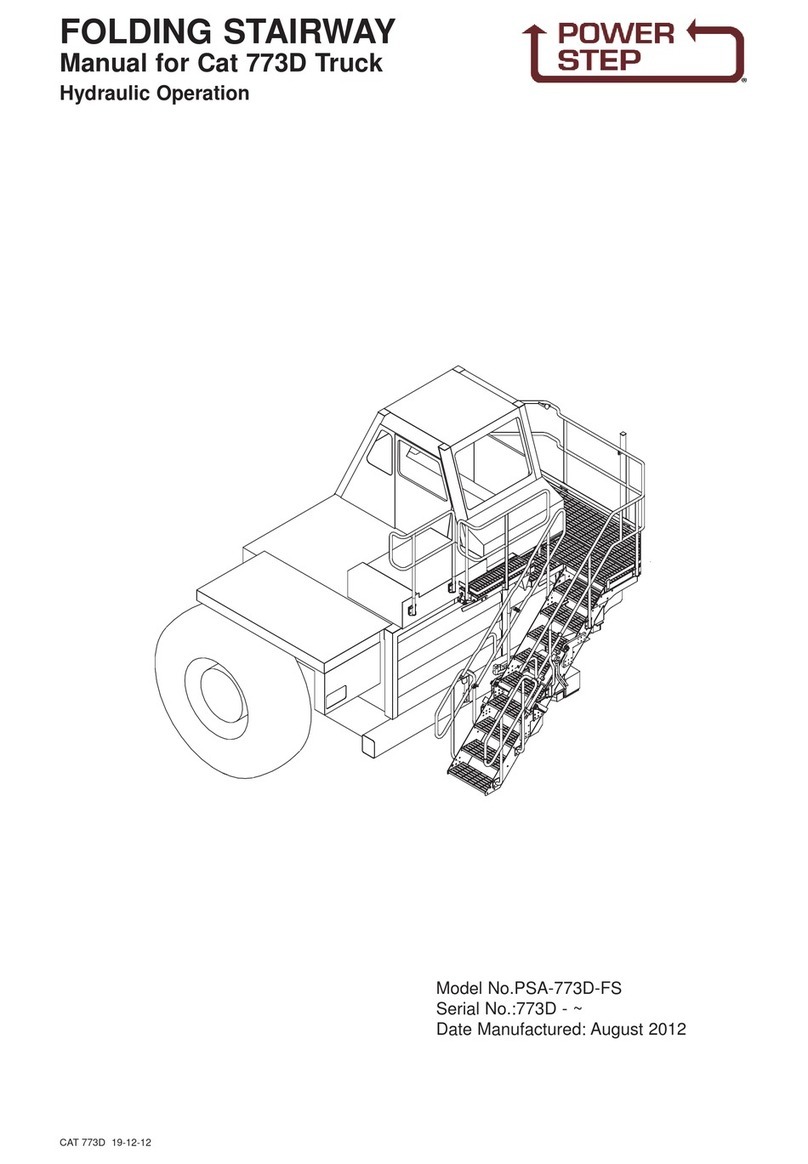

Power Step PSA-773D-FS User manual

Power Step

Power Step PSA-K930E-FS User manual

Power Step

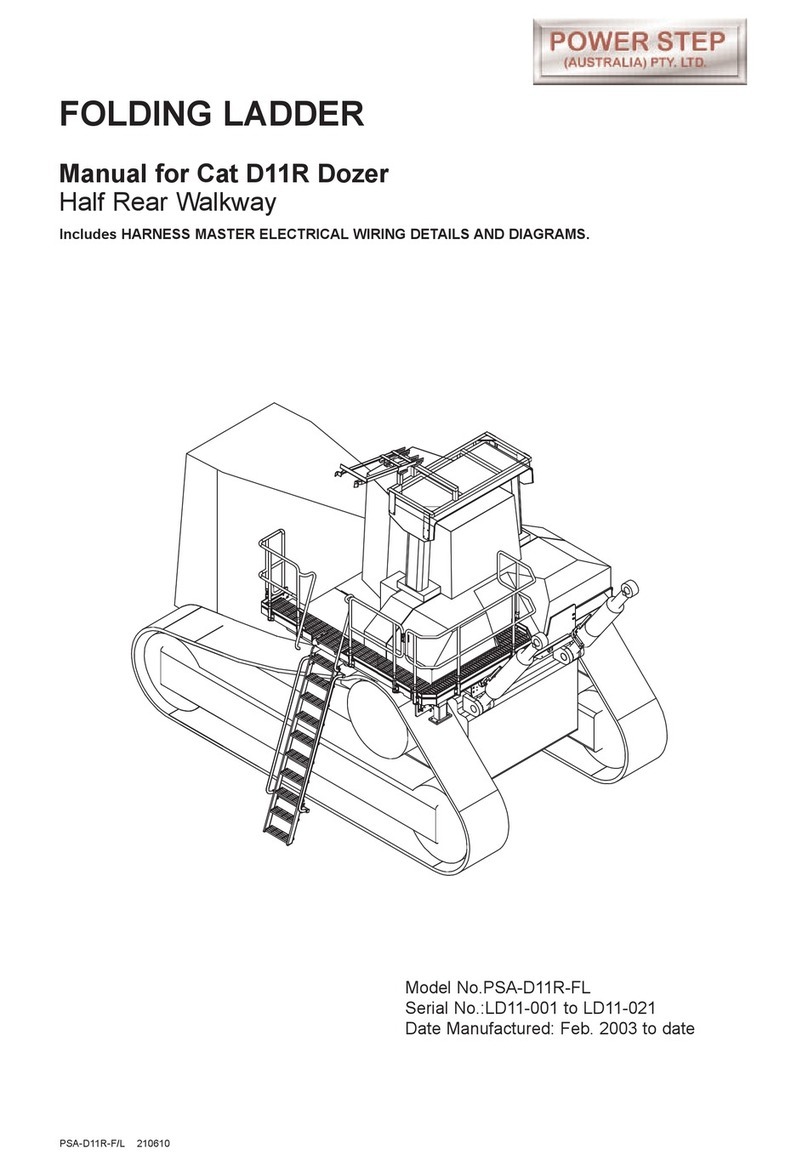

Power Step PSA-D11R-FL User manual

Power Step

Power Step PSA-EX5500-FRS User manual

Power Step

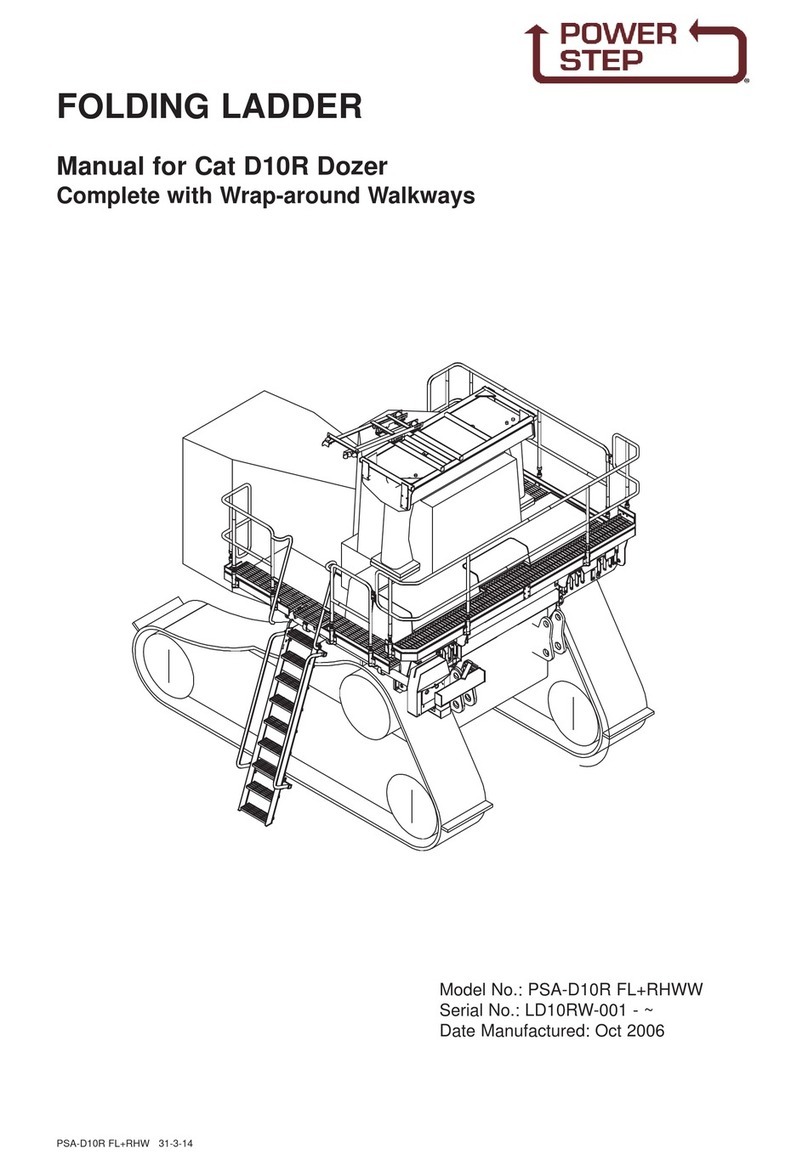

Power Step Cat D10R Dozer User manual

Power Step

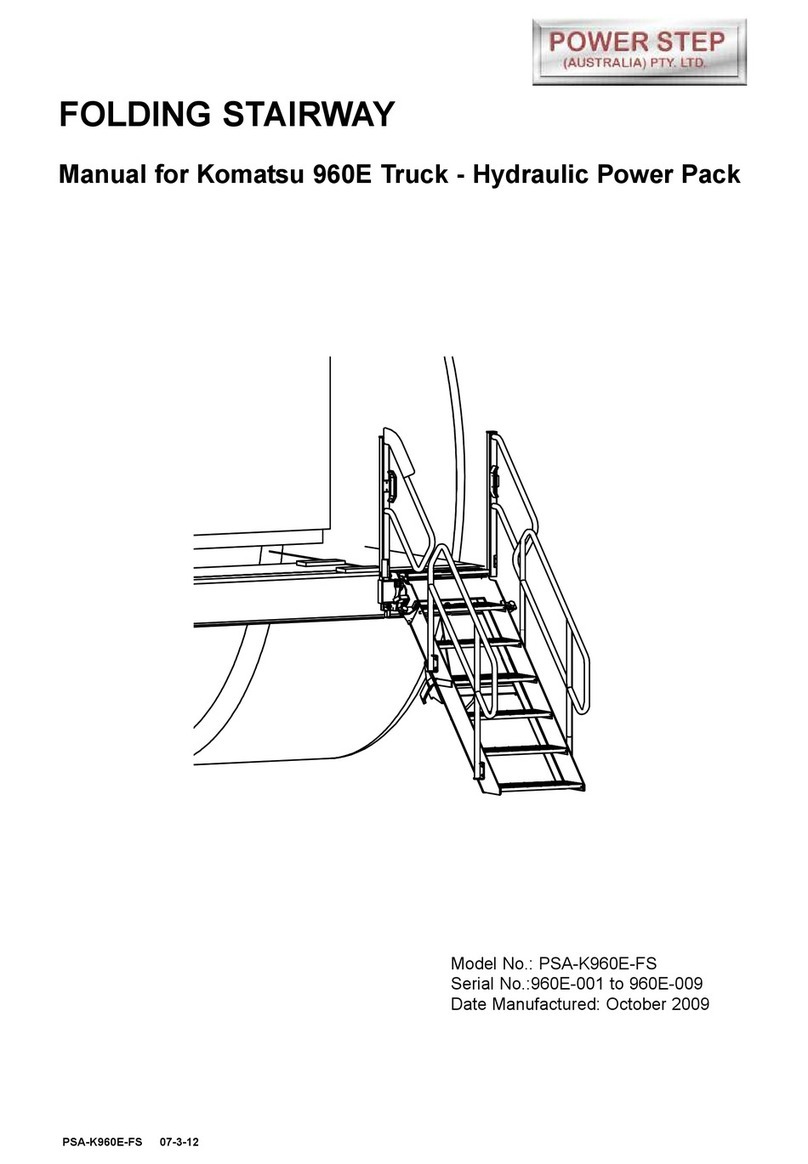

Power Step Komatsu 960E User manual

Popular Ladder manuals by other brands

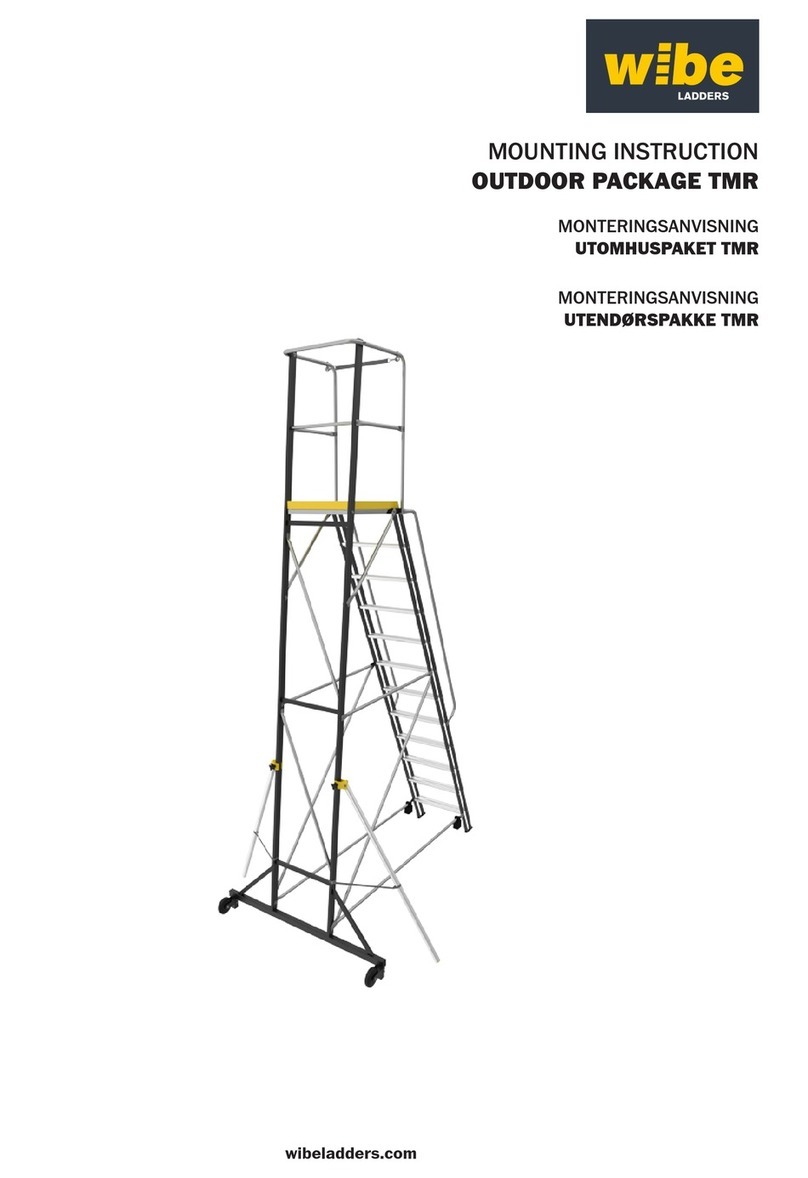

TUBESCA-COMABI

TUBESCA-COMABI 02271 105 à 115 operating manual

ADVANCED SIMRACING

ADVANCED SIMRACING ASR6 Assembly guide

KRAUSE

KRAUSE 1103 Series user manual

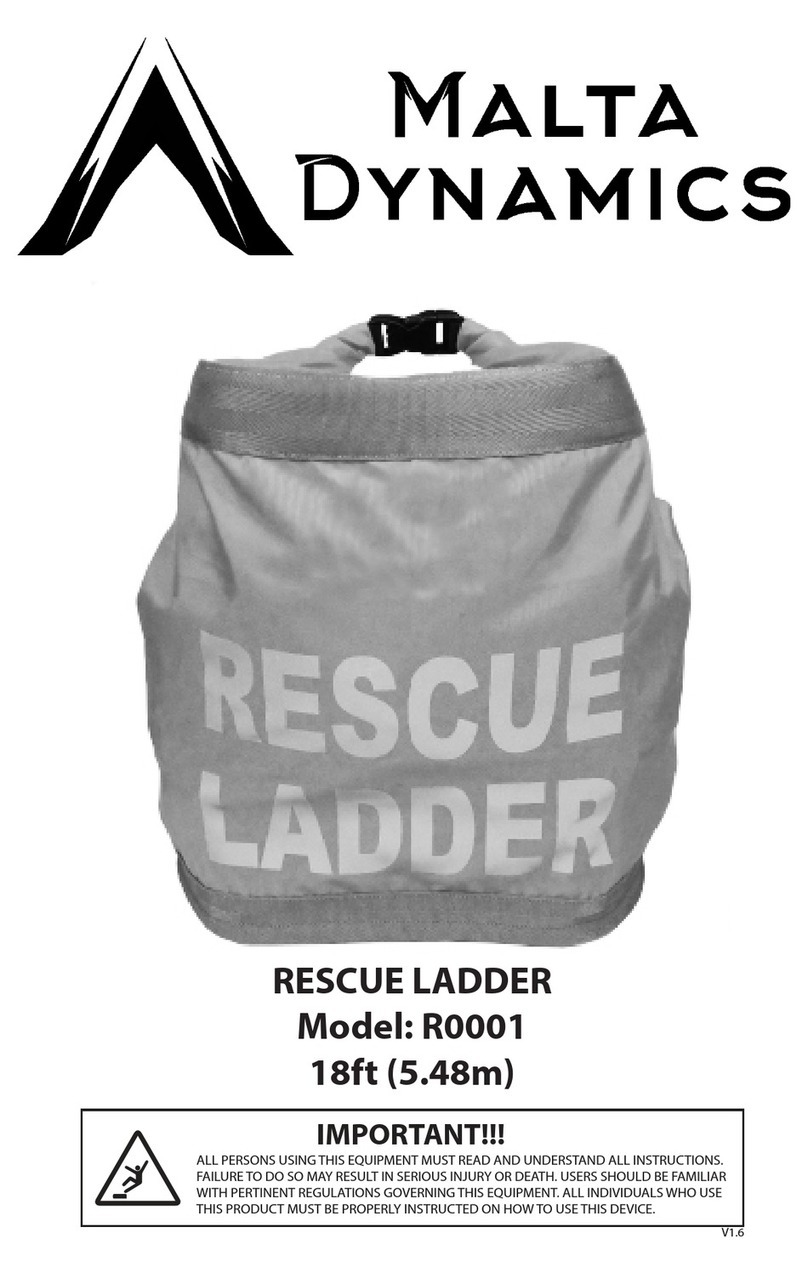

Tractel

Tractel skysafe Assembly and operating manual

AFIX

AFIX FAST FIX Assembly guide

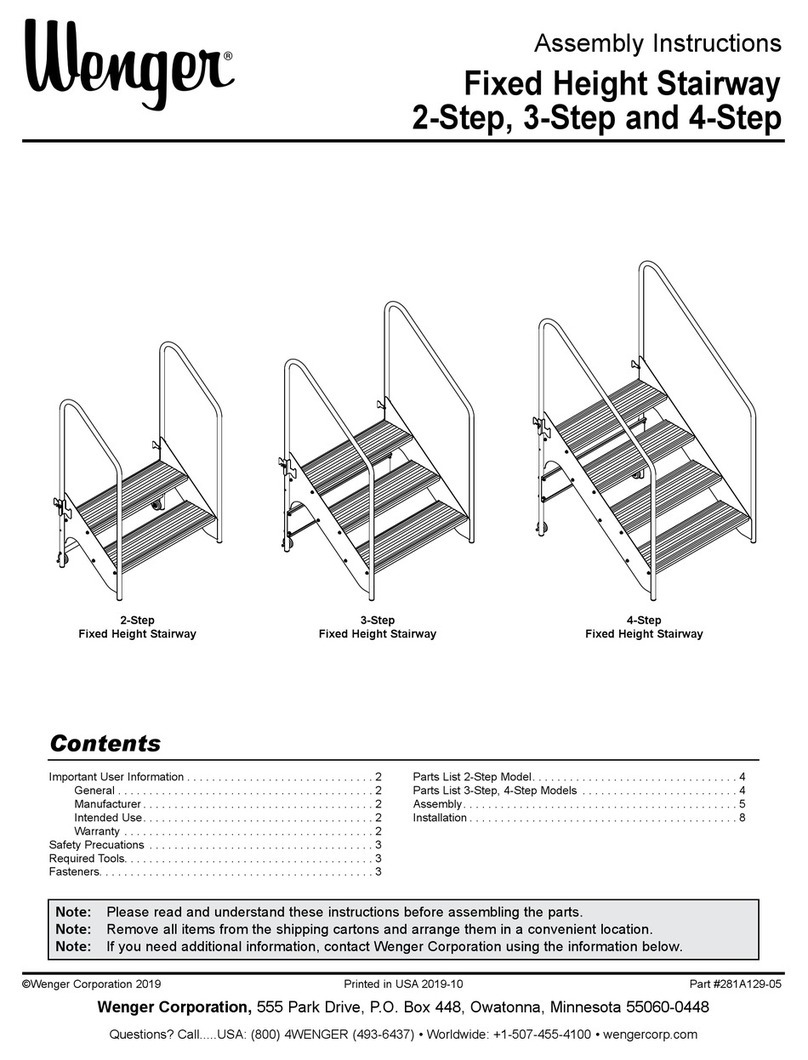

Wenger

Wenger Fixed Height Stairway 2-Step Assembly instructions