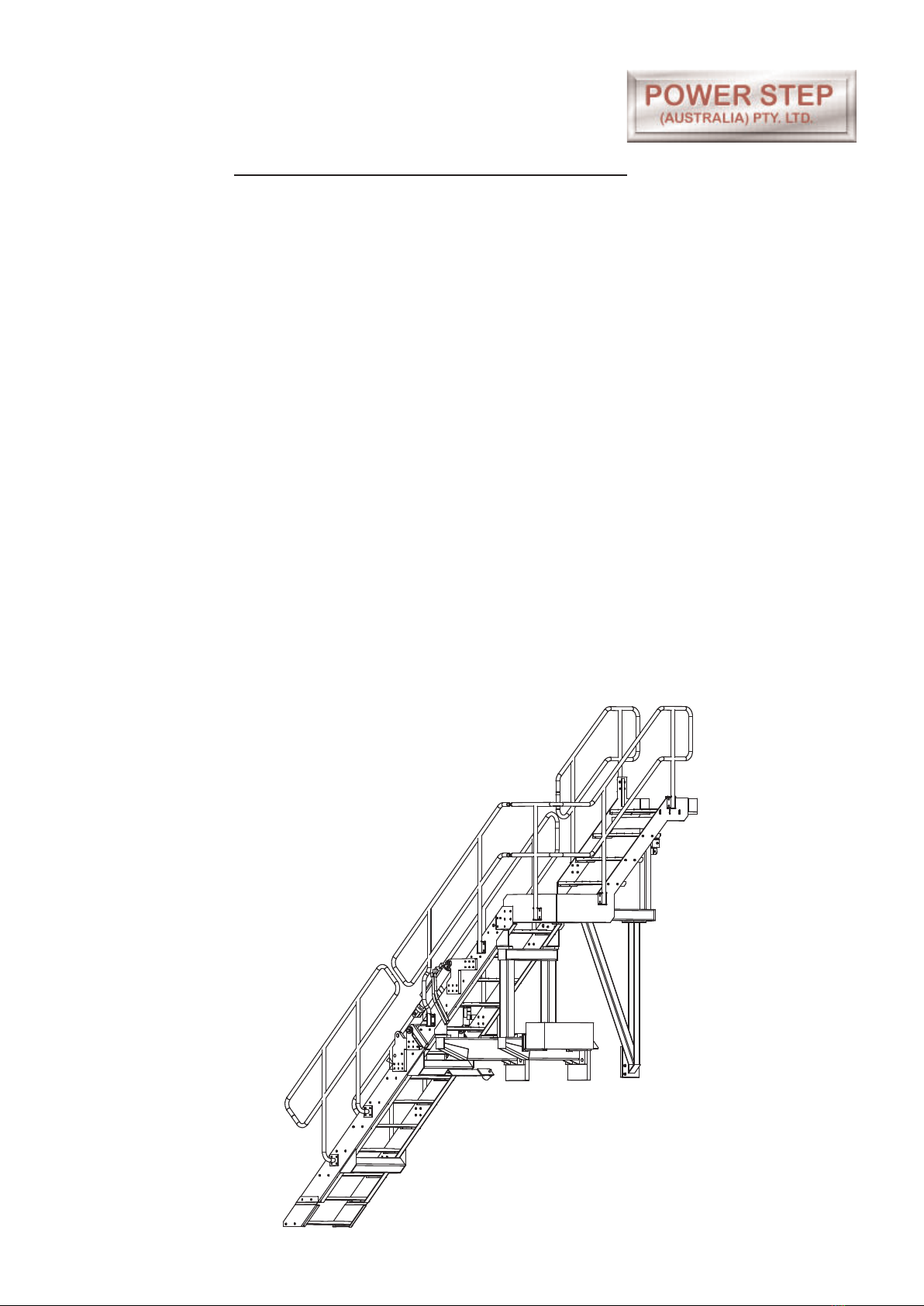

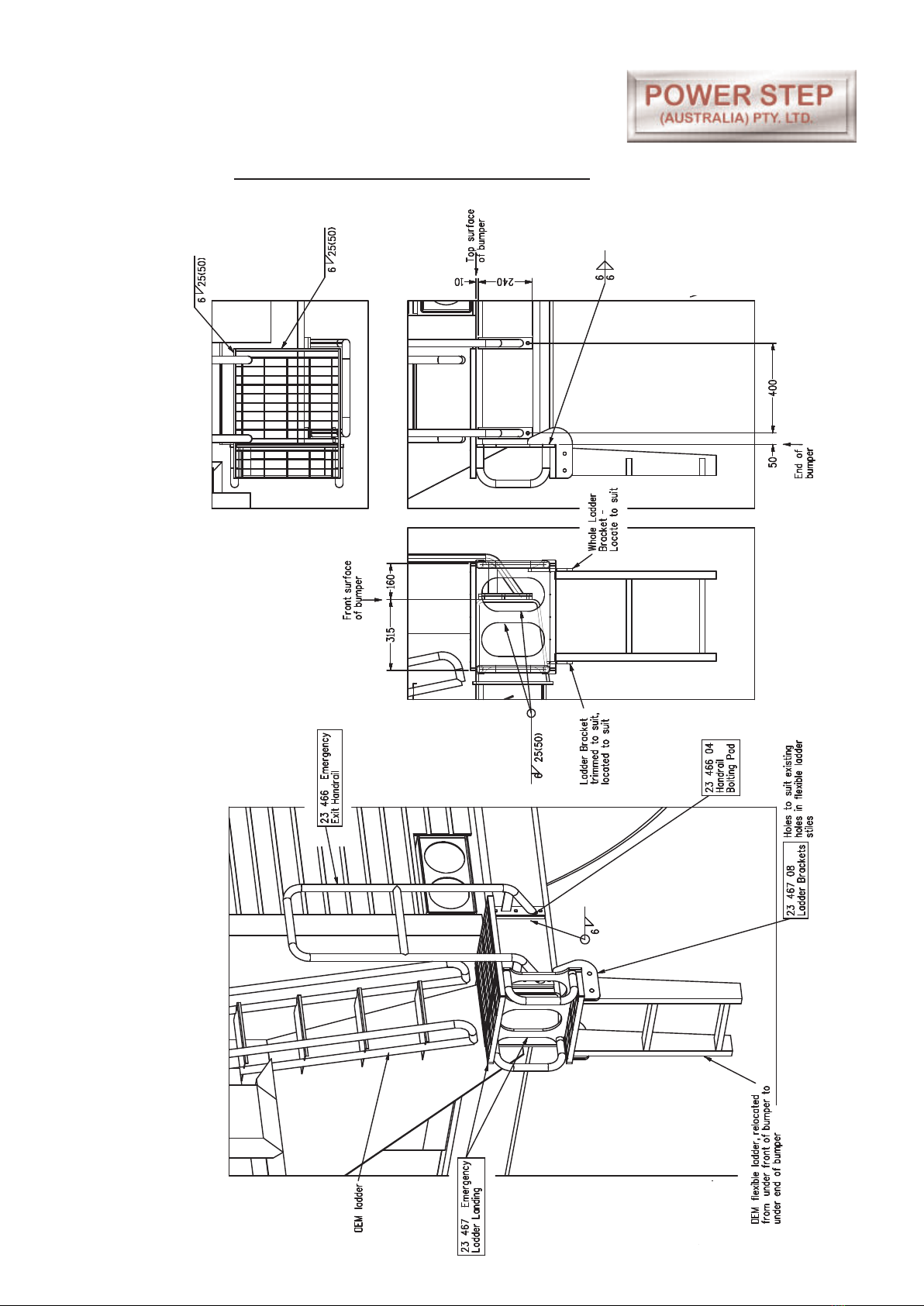

FOLDING STAIRWAY

Caterpillar 789C Haul Truck

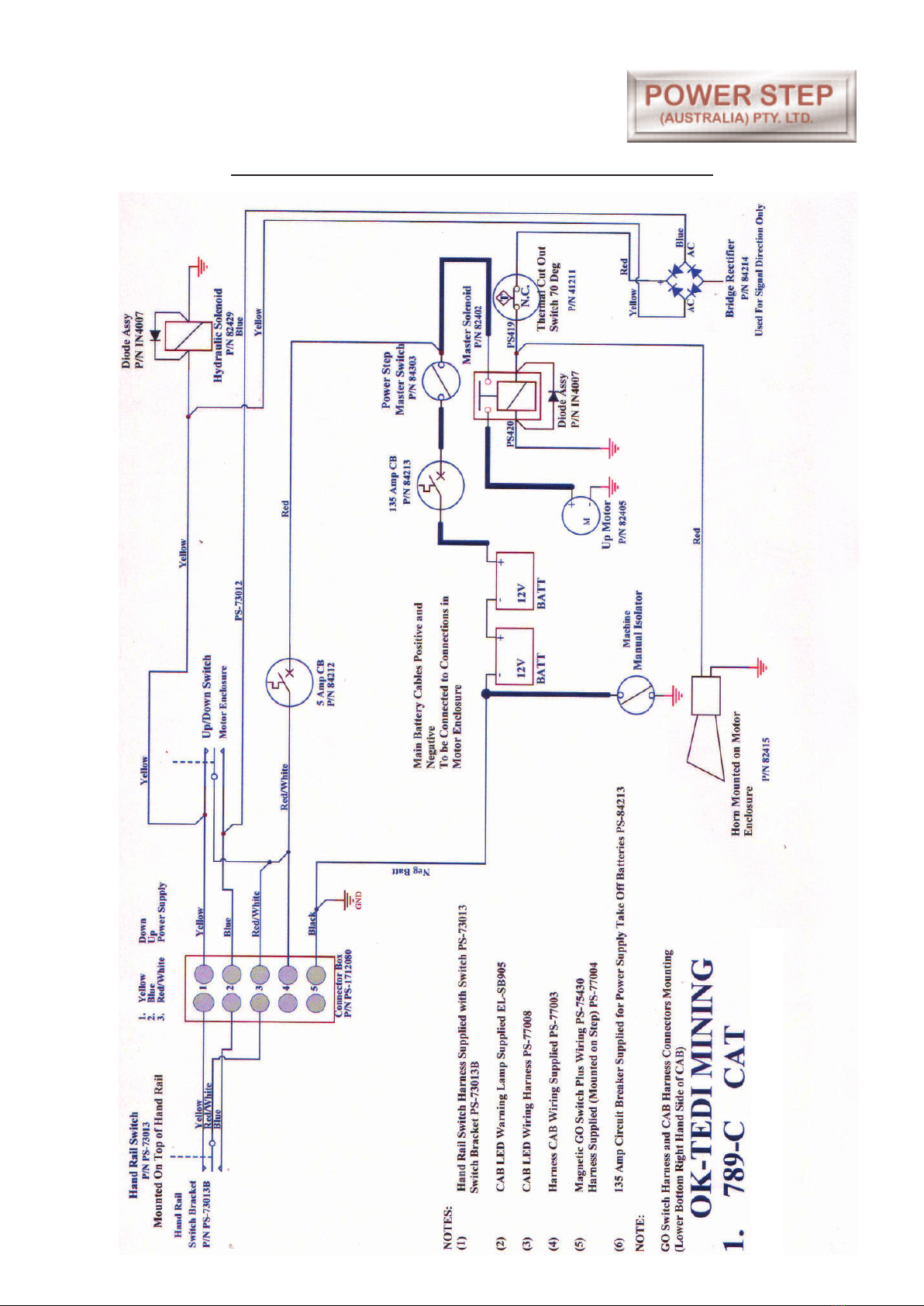

Section 2. Electrical Installation (Cabin & Wiring harnesses)

Refer also to Wiring Diagrams Electrical

Pg9

PSA789C-ASSY 12-3-10

PROCEDURE

Fit Step up/down Warning Beacon in suitable position. (In Cab) as per Photo.

Remove four (4) screws holding Caterpillar fuse panel behind operator's seat. Drill one

hole to insert Caterpillar fuse holder - fit fuse holder, into fuse indicator panel - tighten.

Drill size (12mm or 15/32").

Remove rear access panel from back of cabin and run short conduit through the main

cable gland to inside centre console, ensuring conduit goes underneath control box.

Connect blue wire start from conduit above to blue wire of cabin indicator panel harness.

In rear access, connect black wire, with 10mm eye terminal to machine ground, and blue

wire to outer terminal of newly inserted fuse holder.

Install short blue wire to screw terminal of Caterpillar circuit breaker, and other end to fuse

holder.

Run wiring harness from Power Step Stairway magnetic proximity switch and follow

cabling/hose routing up to air line/ electrical outlet on rear Right Hand Side of cabin.

Drill hole in RH Cabin access panel - route wiring harness in through access panel, and

through to under centre console - connect wires appropriately as colour coded. Hole saw/

drill size (24mm), cable tie harness as appropriate, approximately every 300mm.