FOLDING STAIRWAY

Cat 980G Wheel Dozer

Section 1. Mounting and Installation Mountings PS-24640

Pg 4

PSA-CAT-980G-FL 30-1-13

See Drawings Pg 5 and 6

PROCEDURE

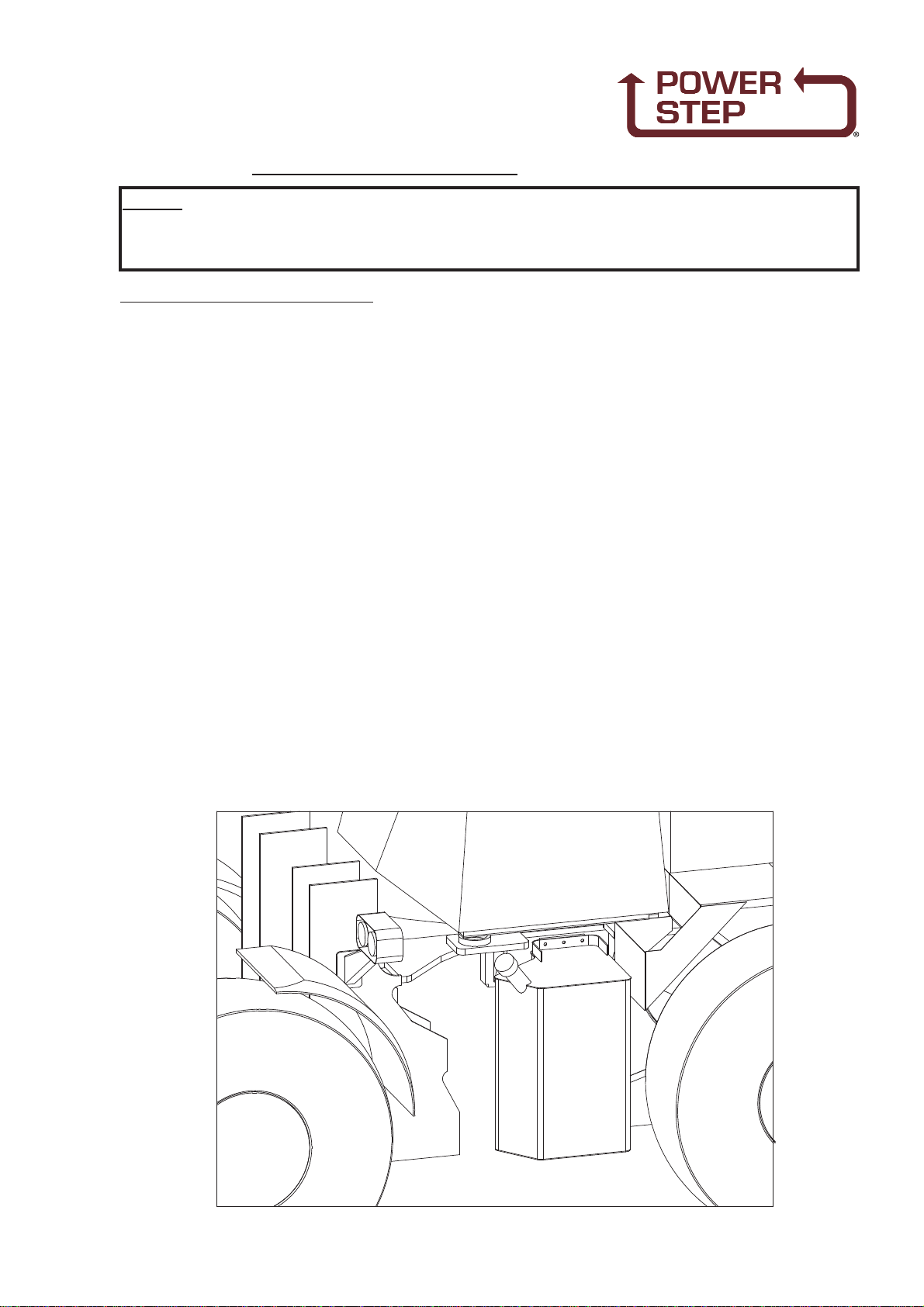

1. Support the fuel tank with blocks and/or jacks to suit. Per View 1,remove the 3

bolts that attach the underside of the fuel tank to the chassis of the machine.

Compare threads of original bolts and Tank Studs. If identical, fit the Tank Studs to

replace the bolts. Per View 2.2, fit the bottom mounting block. Do the same for the

top tank mounting - View 2.1

NOTE THATthe tank might be constructed with it’s back wall continuing down past the

tank floor to the alignment of the bottom mounting boltsper View 1 and View 6.1, or it

might be constructed with the wall plate terminating at floor level per View 6.2. There is

a rebate in the back of the Bottom Mounting Block 23 901 02 to accomodate the continued

back wall plate. If the wall plate terminates at floor level, the Mounting Block Spacer

24 637 should be attached to the Mounting Block per View 6.2 to fill the rebate.

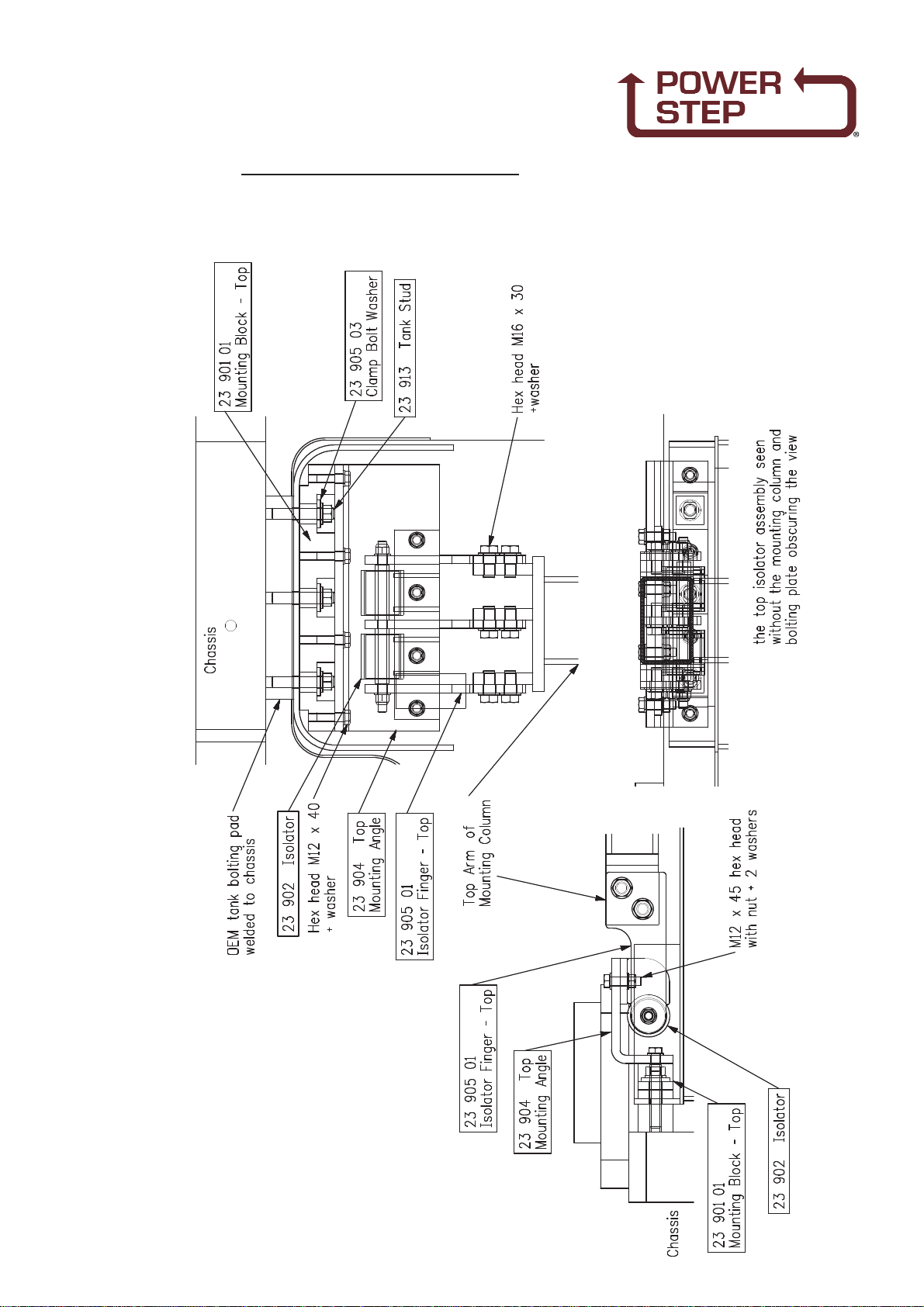

2. Per View 3, check that the M12 tapped holes in the top mounting block are aligned

with the holes in the bottom mounting block. Adjust to suit using the slotted holes in

the mounting blocks. Tighten the nuts on the studs.

3. Per Views 4.1 & 4.2, fit the top and bottom mounting angles to the mounting

blocks.

4. Per Views 5.1 & 5.2, fit the isolators, already assembled with isolator fingers. Note

that the top and bottom isolator fingers are not the same and all have to be fitted

the right way up.

5. Apply post-tightening thread locking compound to all bolts

Use safe lifting and working practices at all times.

NOTE

Follow all on-site/Mine lifting and safety procedures when installing

PSFS to Dozer.