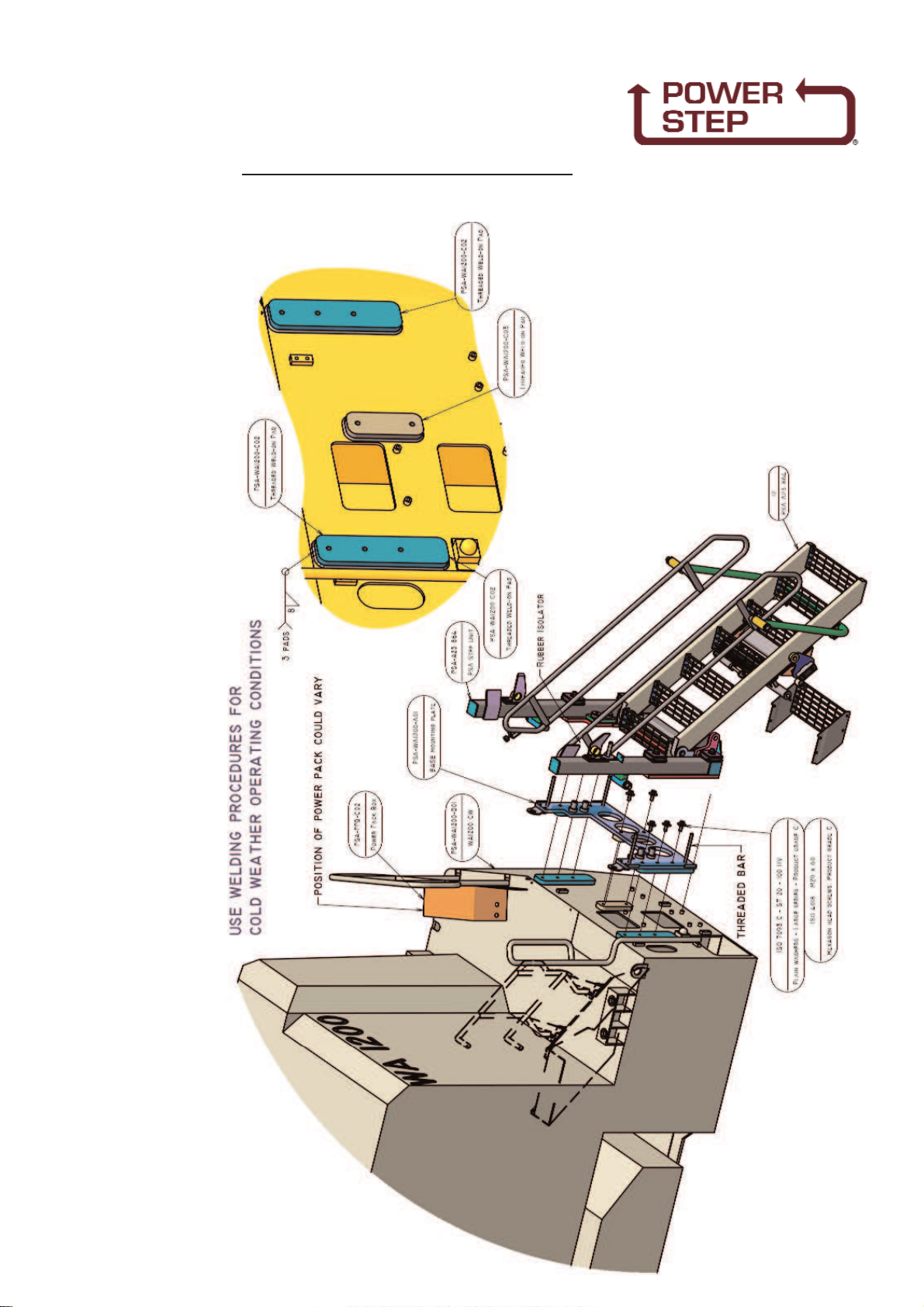

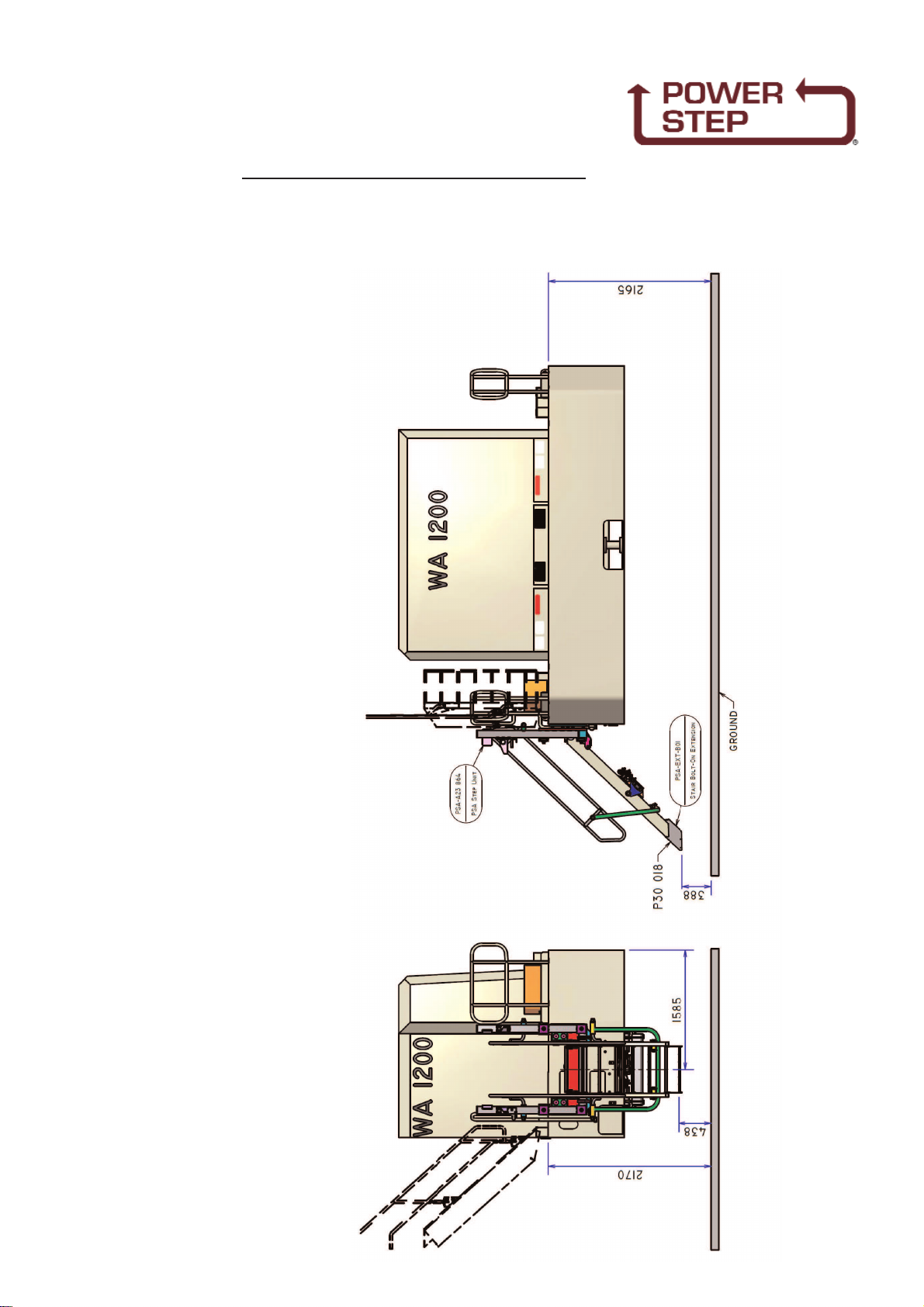

FOLDING STAIRWAY

Komatsu WA1200 Loader

Section 3 Operating Procedure

To Lower Stairway (from the machine)

Position machine in a level, safe area, away from the work face, whenever possible.

Apply park brake and lower engine speed to idle.

Check that the area below the Ladder Access System is clear of people and

obstacles, and lower ladder by operating the two position electrical switch adjacent

to the ladder, to the down position by pressing the switch down.

Hold the switch in the down position until ladder is fully lowered.

If the truck is parked on uneven ground, the bottom of the stairway may touch the

ground before the ladder is in the fully lowered position.

Should this occur, descend the ladder with caution.

To Raise Stairway

Ascend the ladder onto the landing of the Loader.

Ensure the area around the ladder is clear of people and standing to the side, clear

of the area the handrails and ladder raises into, operate the electrical switch to the

raise position (up).

Hold the switch in the up position until the ladder is in the fully raised position.

The ladder is now raised and stored.

Pg9

PSA-KOM-WA1200-FS 30-8-18A

OPERATING NOTES

NOTE: FLOW CONTROL VALVE ADJUSTMENT:

The valve should be positioned to restrict the flow and speed of the Power Step when

lowering. Adjust the knob on top of the valve by turning left or right (clockwise) when the

step is being lowered, until it is lowering at a safe and reasonable speed.

When it is adjusted, lock the adjusting knob by tightening the grub screw located on the

side of the knob.

NOTE: MAGNETIC 'GO' SWITCH ADJUSTMENT:

The switch target trigger area is located on the opposite side and end from the cable entry

point on the switch. Once it is mounted to the switch bracket, adjust the switch in or out

from the stair steel trigger point, to be within 3mm - 10mm from touching each other when

the stair is in the desired rest position.

[DO NOT EXCEED 10MM DISTANCE BETWEEN THE SWITCH AND STRIKER PLATE].

Test by raising and lowering the Power Step a couple of times and adjust again if

necessary.